A combined vertical cable pay-off frame

A pay-off frame and cable technology, which is applied in the field of wire release, can solve the problems of support wheel and chassis wear, affect the construction progress, support wheel burden, etc., and achieve the effect of convenient disassembly and installation, improvement of construction safety, and beautiful style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

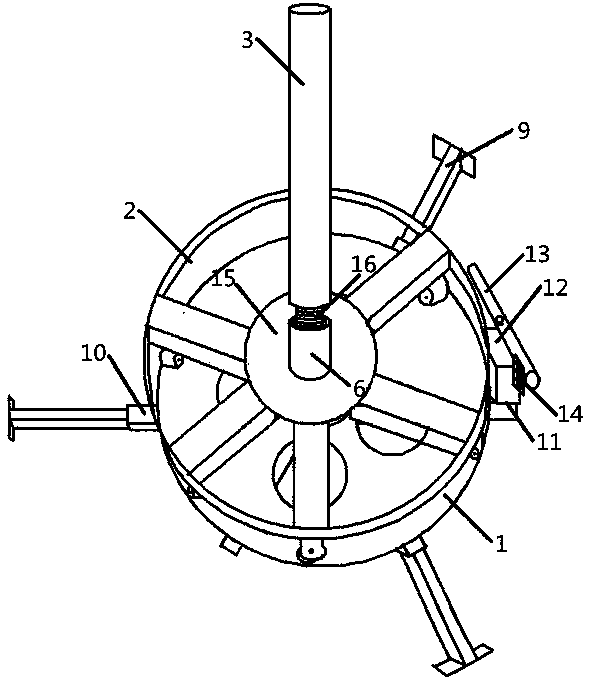

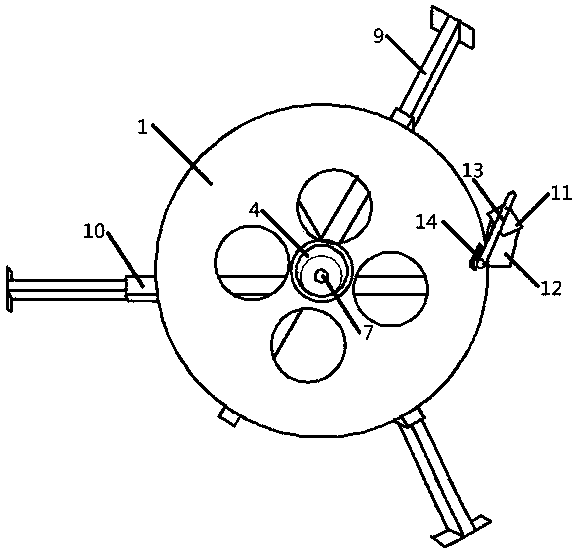

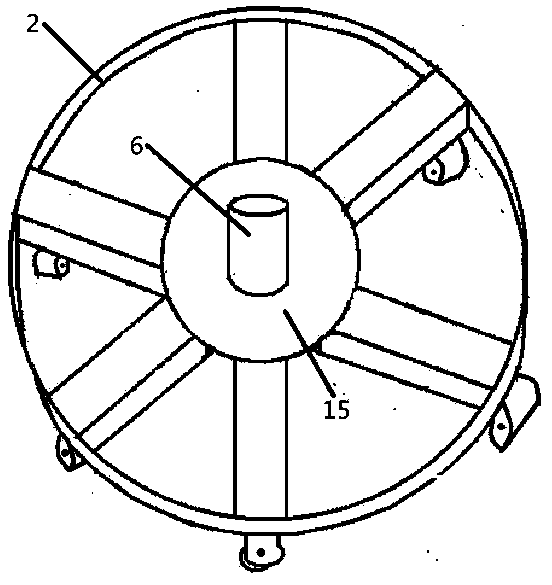

[0024] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

[0025] A combined vertical cable pay-off frame, comprising a base 1 made of cast steel, a runner 2 and a vertical shaft 3, the center of the base 1 is provided with a circular groove 4, and the bottom of the base 1 is provided with three telescopic Fixed rod 9, described telescopic fixed rod 9 is installed in the square tube 10, and described square tube 10 is fixed on the bottom of base 1, and the junction of three square tubes 10 is the center of base 1, and the adjacent square tube 10 The center of the bottom of the runner 2 is provided with a tapered bearing 5, the diameter of the outer ring of the tapered bearing 5 is equal to the diameter of the circular groove 4, and the height of the tapered bearing 5 is the same as that of the circular groove 4. The depth of the shaped groove 4 is equal, the outer edge of the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com