A vertical buoy type decanter

A buoy-type and decanter technology, which is applied in the field of buoyancy decanters, can solve the problems of small water inlet hole area of orifice pipes and muddy water intake, and achieve the effects of constant water outlet flow, prevention of mud running, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

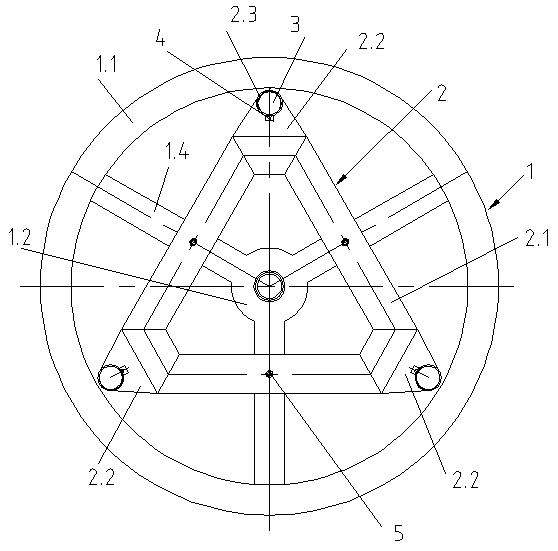

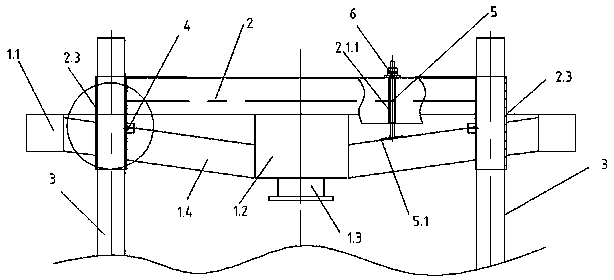

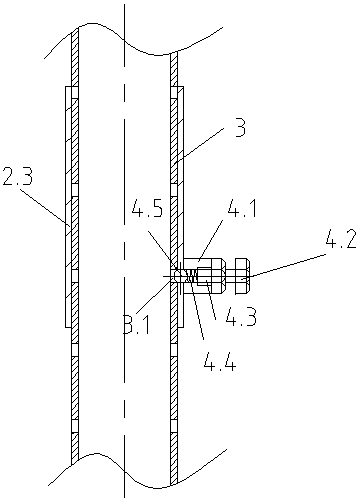

[0012] Embodiment 1: A kind of vertical buoy type water decanter, comprises decanter pan 1, buoy 2 and three guide rods 3, and buoy 2 is the triangle that is spliced by three stainless steel tubes 2.1 that thickness is 1.5mm, and diameter is 250mm, and stainless steel tube The connection of 2.1 is welded with a triangular connecting plate 2.2, and a vertical guide hole is opened on the triangular connecting plate 2.2, and a guide sleeve 2.3 is welded in the guide hole, and the side wall of the guide sleeve 2.3 is provided with a ball regulator 4, and the guide sleeve 2.3 is set on the guide On the rod 3, the guide rod 3 is spaced from top to bottom with adjustment holes 3.1 corresponding to the ball regulator 4, and the decanting tray 1 includes a tray body 1.1, an overflow weir 1.2 arranged at the center of the tray body 1.1, and an overflow weir arranged at the overflow The drainage pipe 1.3 at the bottom of the weir 1.2 and the three connecting arms 1.4 connecting the pan ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com