Heat treatment method for high-lithium-content cast aluminum-lithium alloy

A heat treatment method and casting aluminum technology, applied in the heat treatment of cast aluminum-lithium alloys with high lithium content, and in the field of heat treatment process of cast aluminum-lithium alloys with high lithium content, can solve the problem that aluminum-lithium alloys cannot obtain plasticity, cannot eliminate metal compounds, and alloy plasticity Poor toughness and other problems, to avoid excessive growth, solve low plasticity problems, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

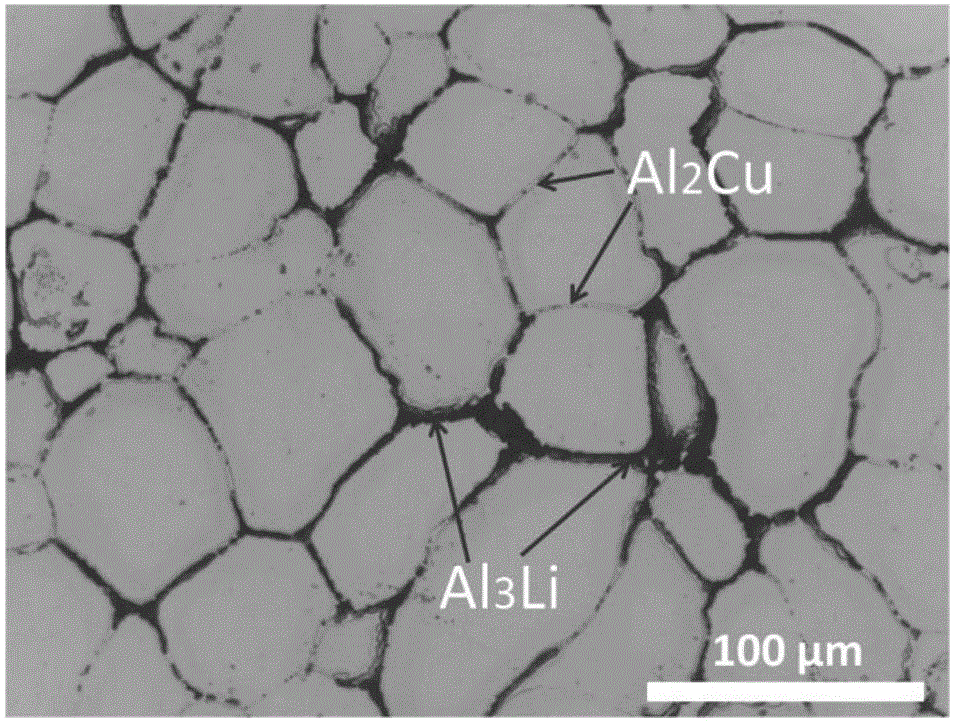

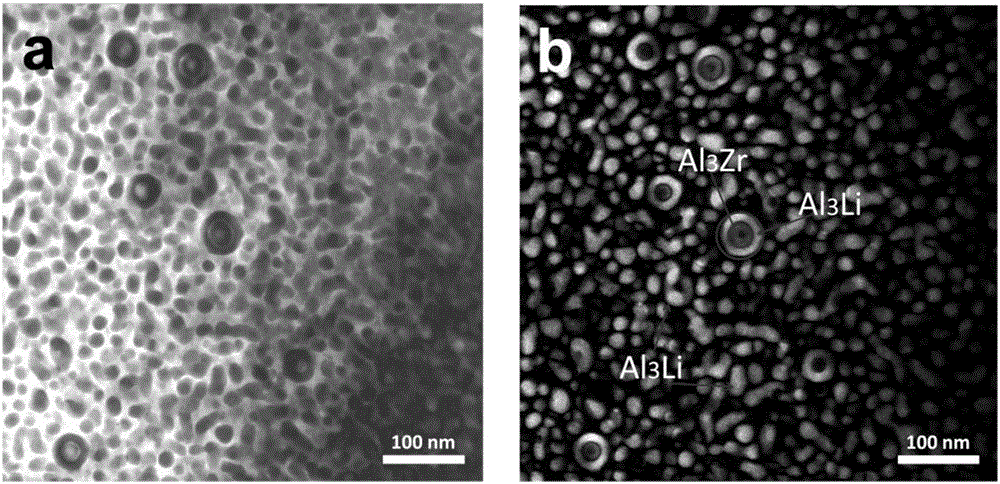

[0031] The cast aluminum-lithium alloy with high lithium content used in this example is a self-made rectangular parallelepiped slab, and its chemical composition is: Li 2.8%, Cu 1.41%, Zr 0.17%, and the rest is Al. The tensile strength in the as-cast state is 130Mpa, and the elongation is 0.6%. Such as figure 1 , the as-cast structure is composed of equiaxed grains, and continuous intermetallic compounds are enriched on the grain boundaries. According to XRD and EDS analysis, it is mainly Al 2 Cu、Al 2 CuLi and Al 3 Li.

[0032] Step 1: First, put the fine sand in a container to dry and heat up in a heat treatment furnace. After the furnace temperature is stabilized at the set first-stage solid solution temperature, the prepared cast aluminum-lithium alloy with high lithium content is buried in dry fine sand. After 10 hours of heat preservation, the temperature was raised to 560°C for 30 hours of heat preservation, and after the heat preservation was completed, it was tra...

Embodiment 2

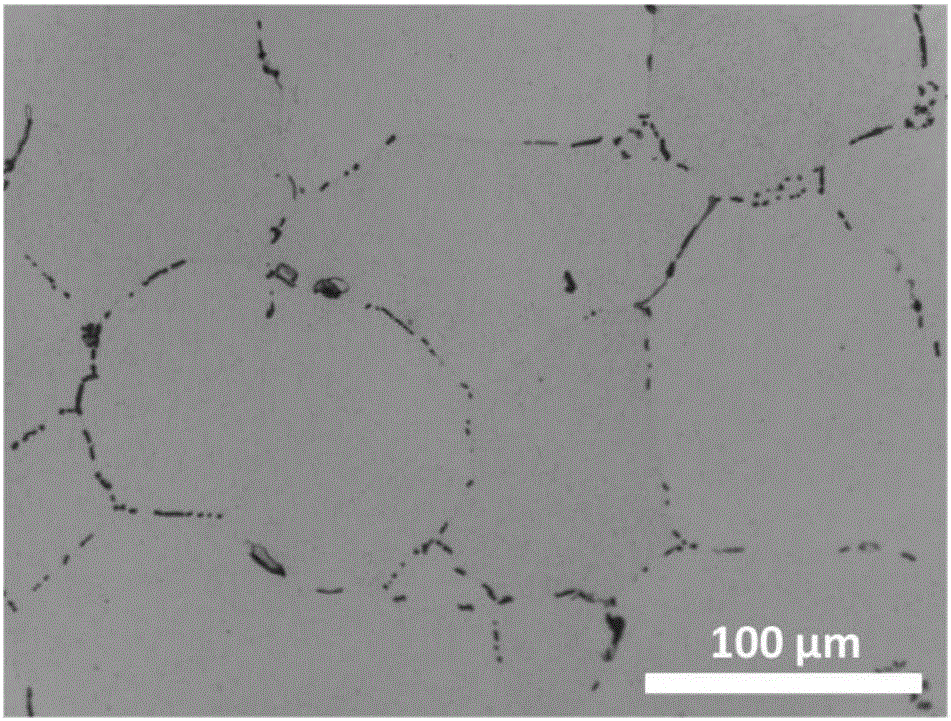

[0044] The cast aluminum-lithium alloy with high lithium content used in the embodiment of the present invention is a self-made cuboid flat ingot, and its chemical composition is: Li 3.1%, Cu 1.52%, Zr 0.18%, Ag 0.31%, Mn 0.4%, and the rest is Al. Previous research by our research group found that manganese (Mn) was added to aluminum-lithium alloys to form Al 6 Mn, Al 6 (FeMn), Al 20 mn 3 Cu 2 phase, can effectively reduce the grain size of the alloy in the as-cast state and after heat treatment, and has a significant effect on improving the plasticity of the aluminum-lithium alloy. In this example, the tensile strength of the alloy in the as-cast state is 145Mpa, and the elongation is 0.3%. Such as Figure 4 , the as-cast structure of the alloy in this example is also composed of equiaxed grains, and continuous intermetallic compounds are enriched on the grain boundaries. According to XRD and EDS analysis, it is mainly Al 2 Cu、Al 2 CuLi and Al 3 Li. Compared with Ex...

Embodiment 3

[0057] The cast aluminum-lithium alloy with high lithium content used in the embodiment of the present invention is a self-made cuboid flat ingot, and its chemical composition is: Li 2.93%, Cu 1.46%, Zr 0.18%, Ag 0.44%, Mn 0.48%, and the rest is Al. In this example, the tensile strength of the alloy in the as-cast state is 149Mpa, and the elongation is 0.4%. The as-cast structure of the alloy in this example is also composed of equiaxed grains, and continuous intermetallic compounds are enriched on the grain boundaries. According to XRD and EDS analysis, they are mainly Al2Cu, Al2CuLi and Al3Li.

[0058] Step 1: First, put the fine sand in a container to dry and heat up in a heat treatment furnace. After the furnace temperature is stabilized at the set first-stage solid solution temperature, the prepared cast aluminum-lithium alloy with high lithium content is buried in dry fine sand. After 20 hours of heat preservation, the temperature was raised to 560°C for 30 hours of he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com