Self-install oil production platform and installation method thereof

An oil production platform and an installation method technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of high installation costs, large investment, and affecting the progress of project installation, so as to reduce construction costs, improve rigidity and resistance The effect of wave power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

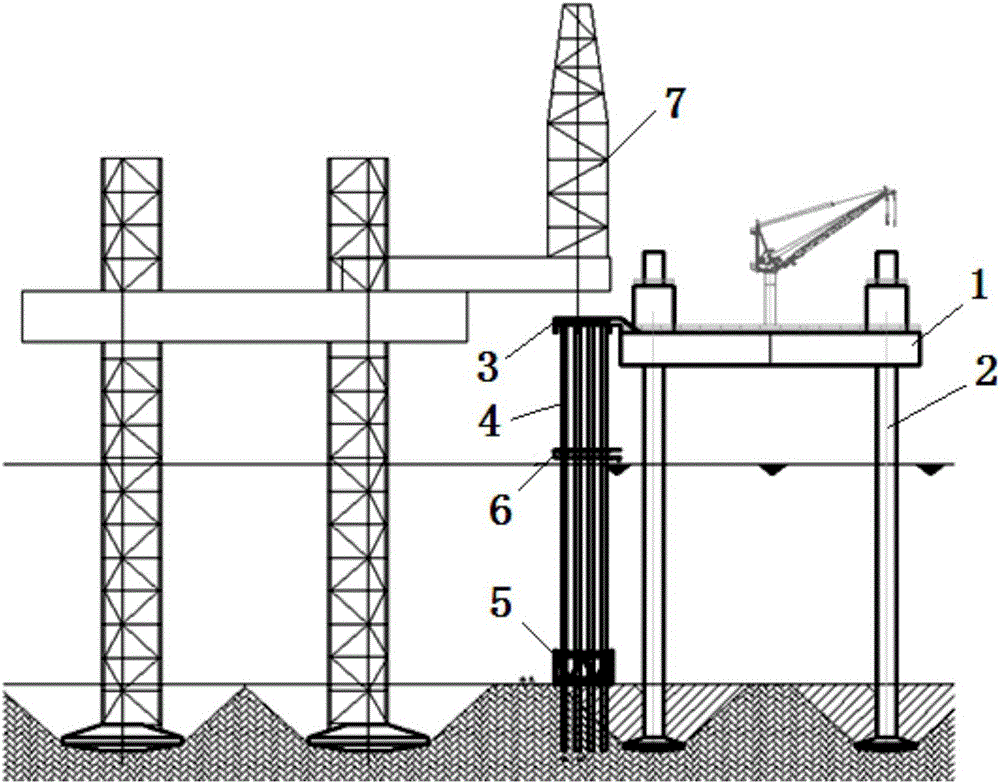

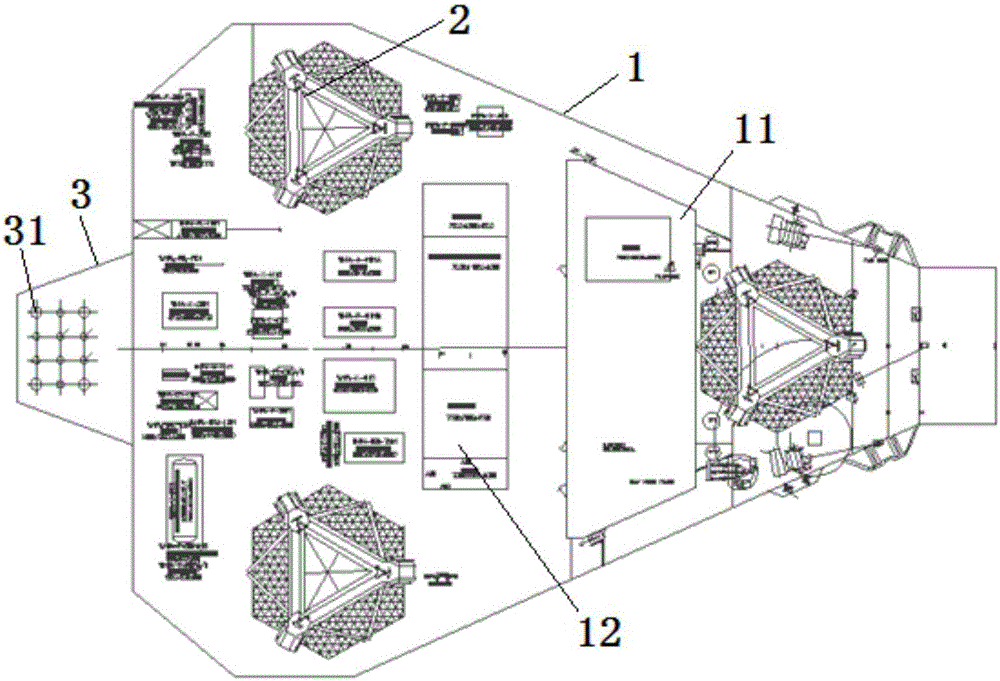

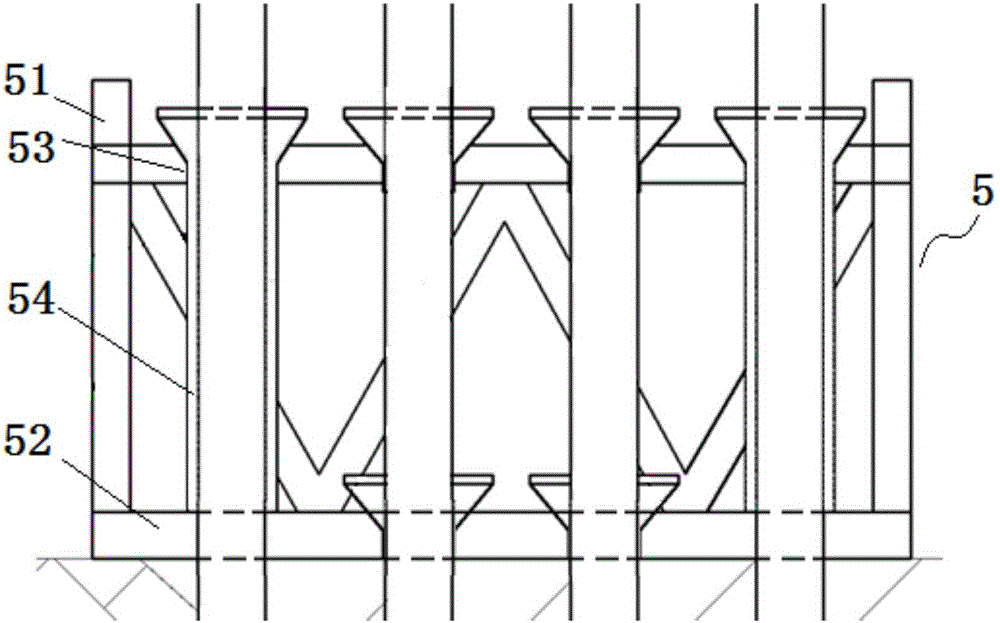

[0021] Such as figure 1 , figure 2 , image 3 As shown, the device of the present invention includes a platform 1 floating on the sea surface, and a plurality of liftable legs 2 inserted in the seabed are arranged at the bottom of the platform 1 . On one side of the platform 1, there is a wellhead area 3 that extends outwards so that the drilling ship can drill wells in place. A plurality of wellheads 31 are opened on the wellhead area 3, and a water-proof jacket is arranged in each wellhead 31. Pipes 4 form a Christmas tree, and one end of each water-resistant casing 4 communicates with the wellhead 31, and the other end is vertically inserted on the seabed. Each water-resisting casing 4 also runs through the underwater base plate 5 arranged on the bottom surface of the seabed. The underwater base plate 5 and the wellhead area 3 are positioned up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com