Self-installation deep draft production and storage platform

A deep draft, self-installation technology, applied in transportation and packaging, special-purpose ships, ships, etc., can solve problems such as construction resource dependence, and achieve the effect of reducing development costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

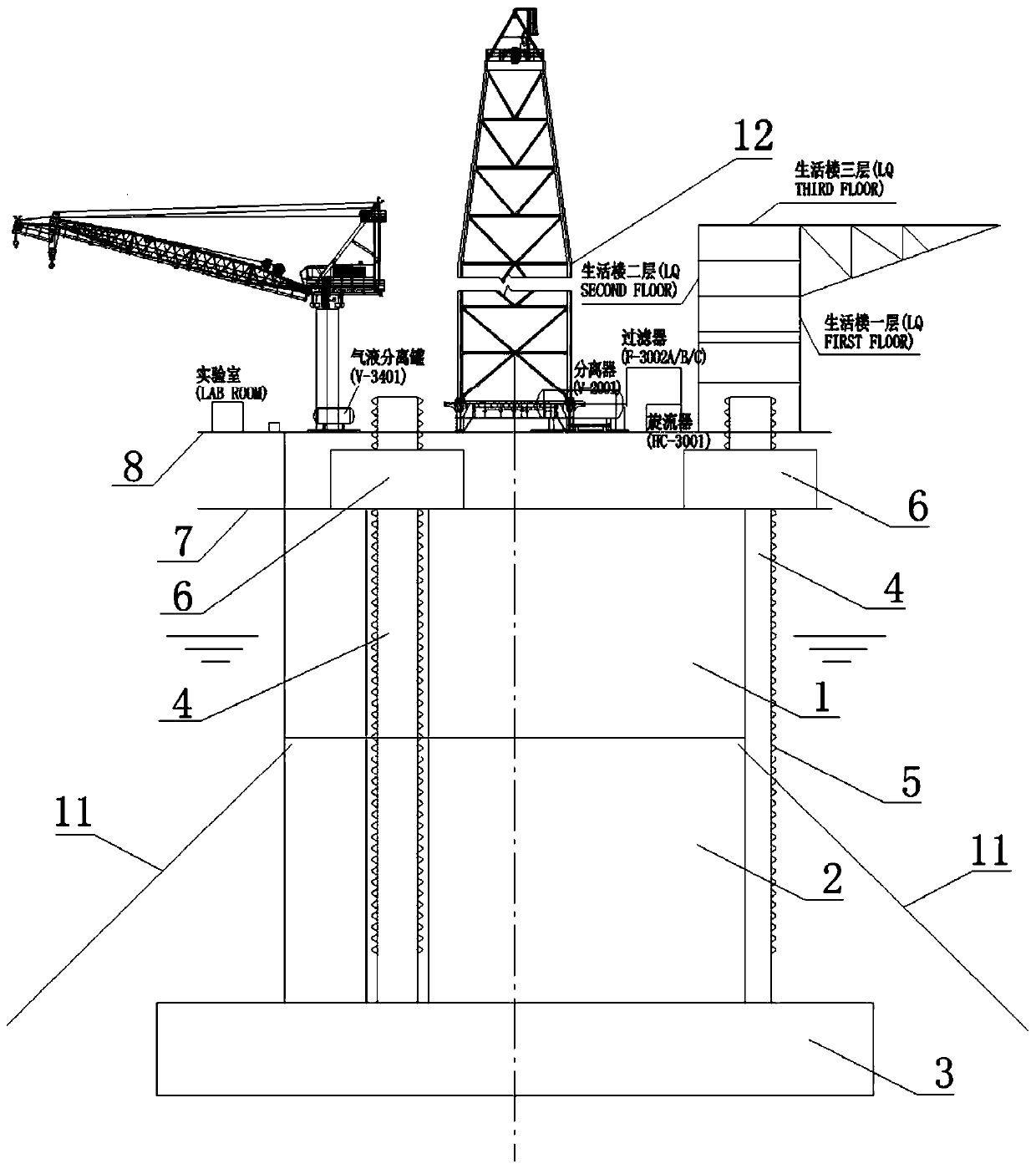

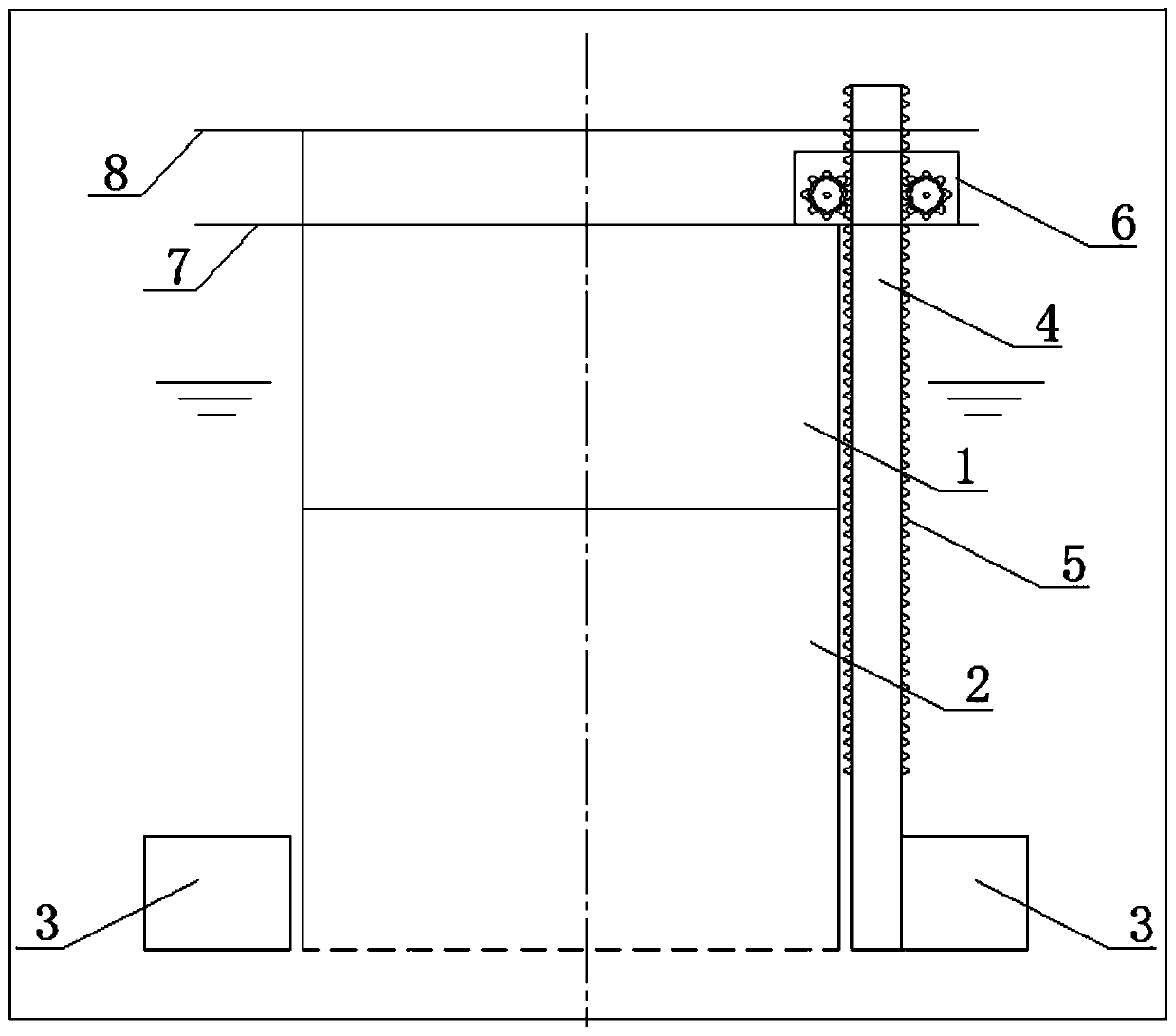

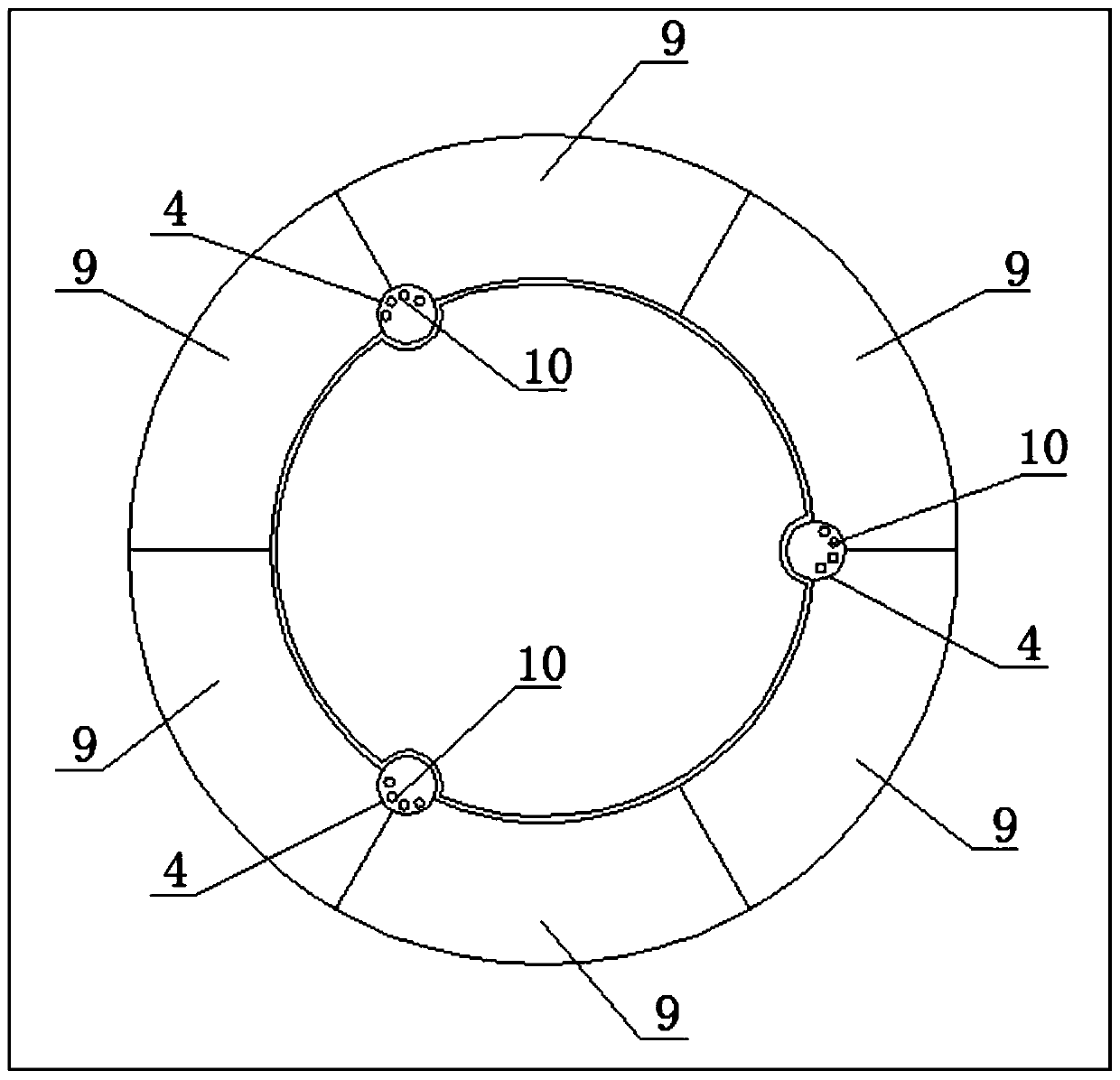

[0025] Such as figure 1 — image 3 As shown, the present invention includes: a floating body 1, an oil recovery production treatment module arranged on the upper part of the process deck 8 of the floating body 1, a platform drilling rig 12 arranged on the upper part of the process deck 8 of the floating body 1, an extension shell arranged on the lower part of the floating body 1 and extending downwards body structure 2, an annular structure 3 arranged under the extension shell structure 2, wherein the cross section of the extension shell structure 2 is consistent with the cross section of the floating body 1, and the bottom of the extension shell structure 2 is provided with an opening, the opening The hole is connected to the seawater; the upper part of the annular structure 3 is rigidly connected to the leg 4 by welding or bolts, and the leg 4 is connected to the floating body 1 through the gear device 6 arranged on the main deck 7 .

[0026] The above-mentioned ring struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com