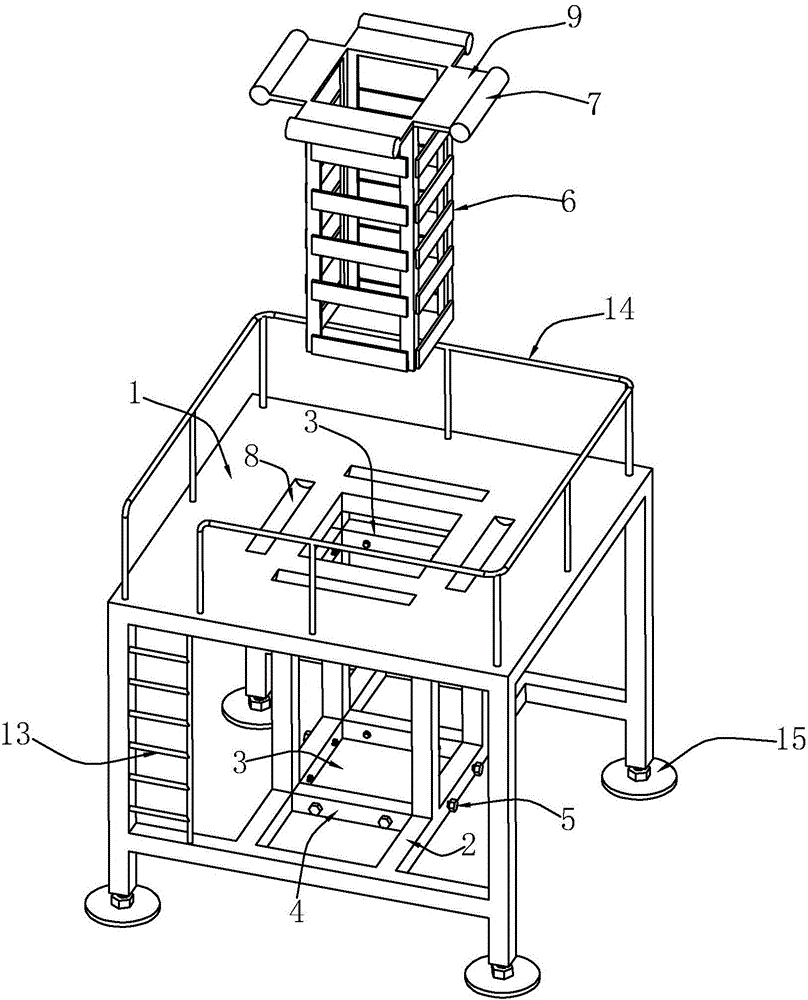

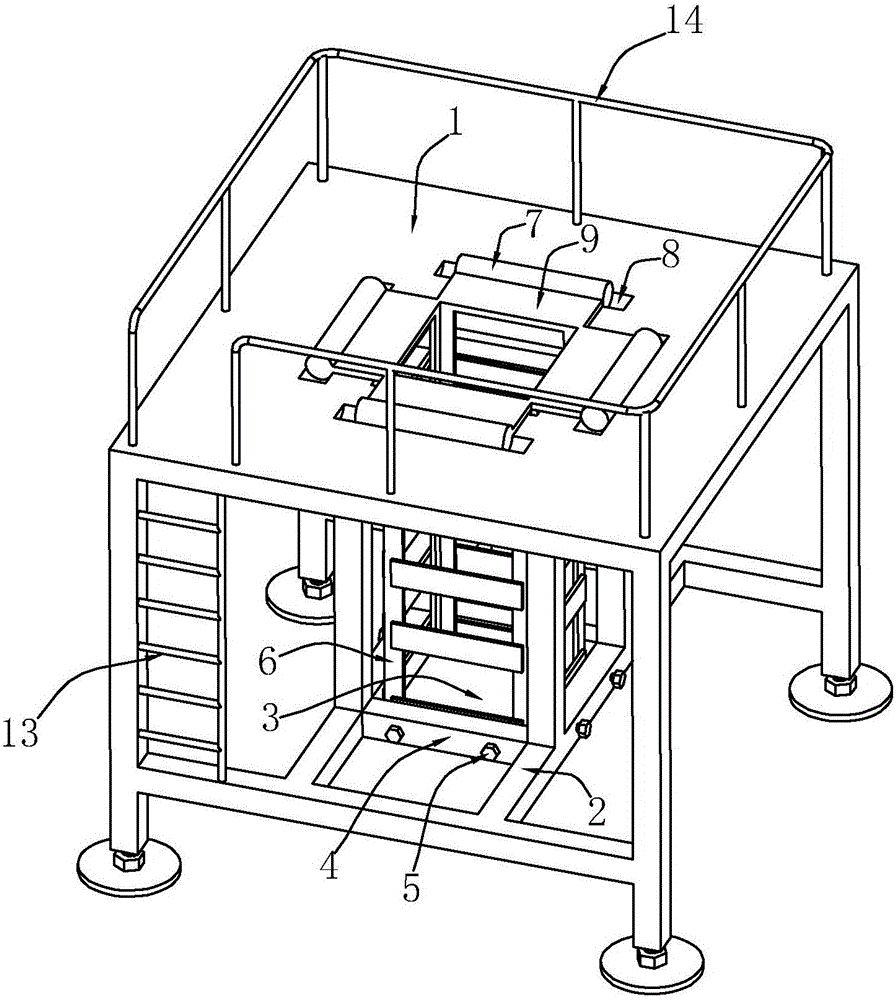

Construction method for embedding latticed column through reverse building method

A construction method and lattice column technology, which are used in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of positioning and direction accuracy, and difficult to control verticality, and achieve the effect of easy control and easy verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

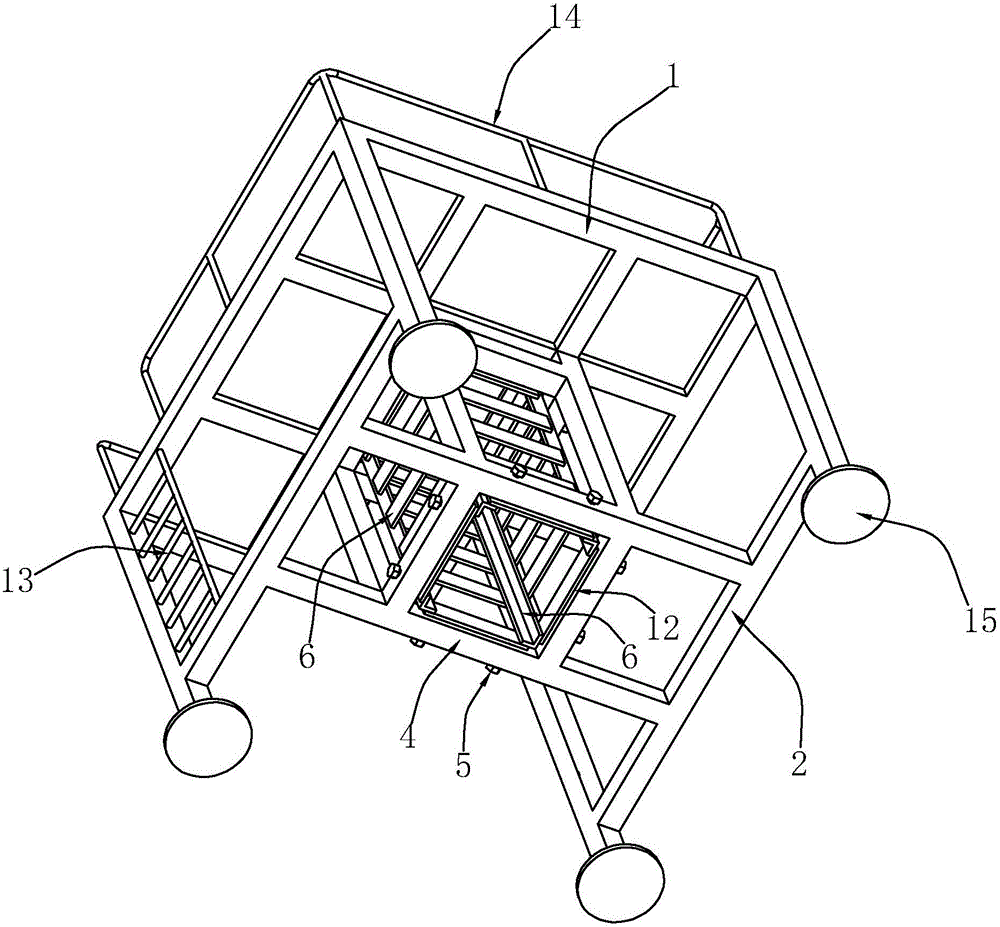

[0046] Embodiment 2, a construction method of pre-embedded lattice column by reverse method, comprising the following steps:

[0047] 1) Customized positioning frame,

[0048] The positioning frame is the same as the first embodiment;

[0049] 2) The site is flat,

[0050] Before the pile holes are formed, repair and reinforce the damaged parts and trenches on the site to ensure that the positioning frame is placed stably; site reinforcement measures: measure the positions of the four feet 15 on the ground through measurement and lofting, and excavate with equal length, width and height. For a 500mm pothole, pour concrete, smooth the concrete surface, and install the positioning frame after 15 days;

[0051] 3) Pile stake out,

[0052] When setting out, multiple checks and reviews must be carried out, and a cross centerline is set at the hole. The center of the cross centerline follows the principle of coincident with the centerline in the vertical direction of the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com