Closestool

A technology for toilets and sewage pipes, which is applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of air leakage, stability and sealing effect that are not as good as water sealing structures, and the sealing effect is easy to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

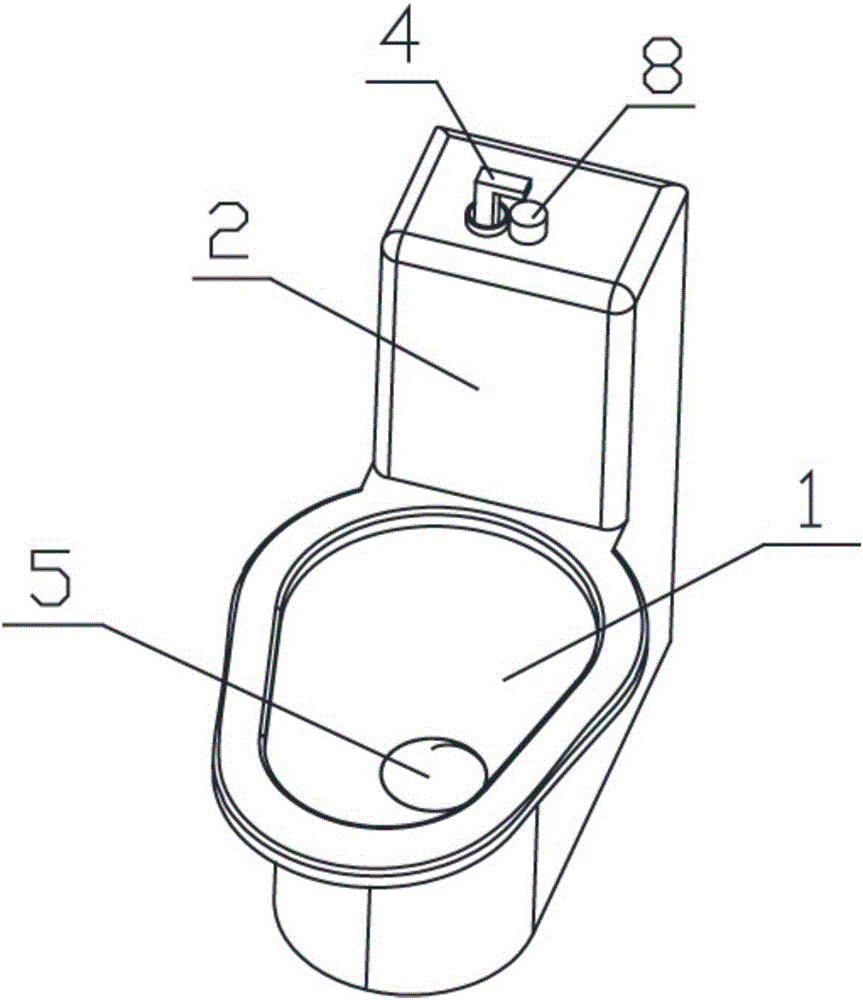

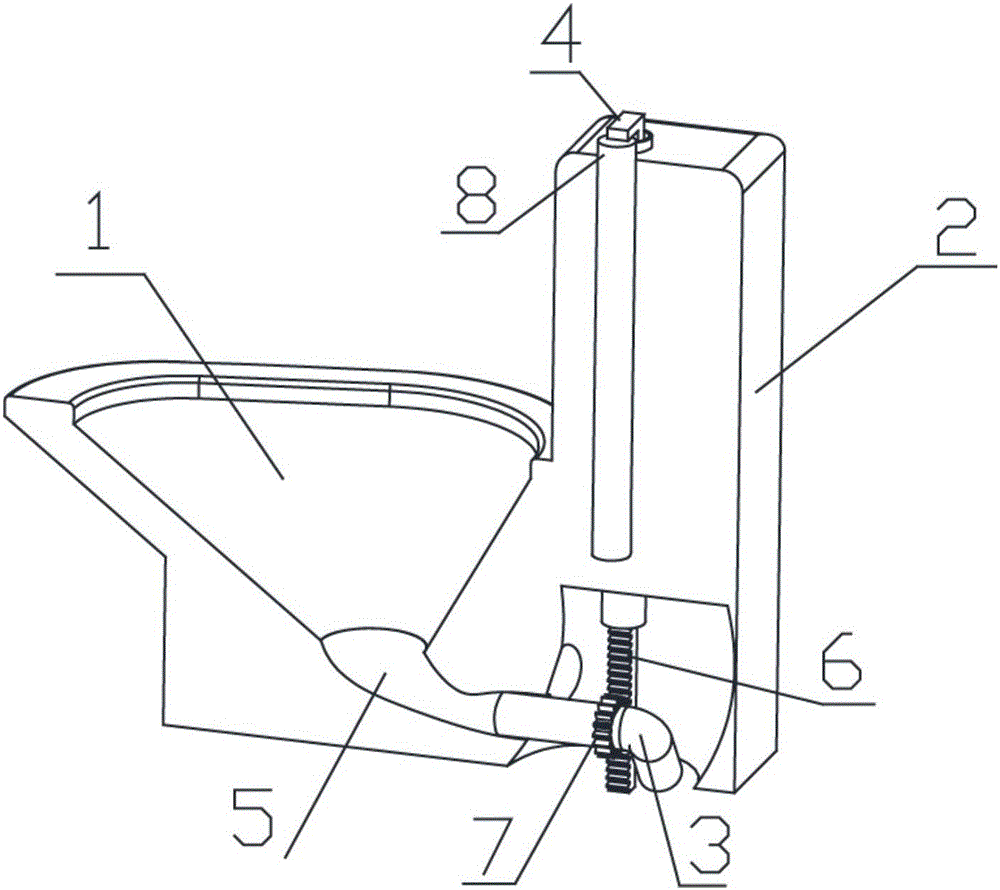

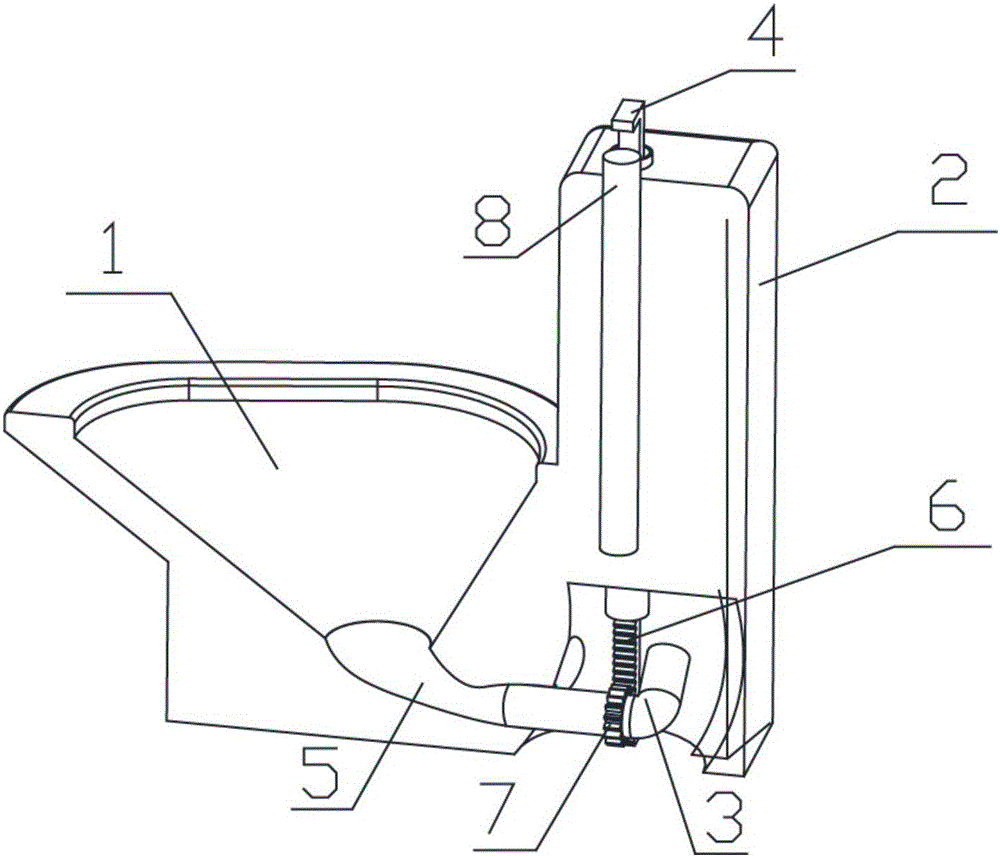

[0031] to combine Figure 1 to Figure 3 As shown, a toilet provided by the embodiment of the present invention includes a sewage pipe 3, the inlet end of the sewage pipe 3 communicates with the sewage outlet 5 of the barrel body 1, and the outlet end of the sewage pipe 3 is accommodated in the sewer and can be turned upside down . After the outlet end of the sewage pipe 3 is turned upwards, that is, the outlet end of the sewage pipe 3 can be as high as above the sewage outlet 5 of the barrel body 1, or at least higher than a part of the sewage pipe 3 connected with the outlet end, Thus, a U-shaped water storage channel can be formed, and a water seal can be formed between the inner space of the bucket body 1 and the sewer through the U-shaped water storage channel; That is, the outlet end of the sewage pipe 3 can be lowered to below the sewage outlet 5 of the barrel body 1 or the rest of the sewage pipe 3, or at least lower than the outlet end in the upturned state, that is, ...

Embodiment approach

[0035] The outlet end of the sewage pipe 3 is provided with a bending part, which is a curved section of the sewage pipe 3, such as an L-shaped curved structure; The mouth 5 is connected by rotation, that is, the inlet end of the sewage pipe 3 can be arranged in two separate sections, and the two sections are connected by rotation, or the sewage pipe 3 and the sewage outlet 5 of the barrel body 1 are rotated. The way of connection, these two ways can make the outlet end where the bending part is located to turn up and down through its own rotation; moreover, on the sewage pipe 3 and between the inlet end and the outlet end of the sewage pipe 3 There is also a gear 7, that is, the gear 7 is located on the part of the sewage pipe 3 between the rotating connection part or the rotating connection position and the bending part, and can specifically be sleeved on the part of the sewage pipe 3; in addition, A control rod 4 is set, and a bar-shaped tooth 6 is arranged at the bottom en...

Embodiment 2

[0042] The toilet provided by the second embodiment of the present invention is different from the first embodiment in that:

[0043] to combine Figure 1 to Figure 3 As shown, the top of the control rod 4 is not fixedly connected with the drain switch 8 of the water tank 2 or moves downward synchronously, but a pressing part is provided on the top of the control rod 4, and the pressing part is arranged at intervals between the drain switch 8 of the water tank 2. 8, used to trigger the drain switch 8 in the process of falling, so that the water tank 2 is drained. That is to say, before triggering the drain switch 8, the control rod 4 has moved down a certain distance in advance, so that the outlet of the sewage pipe 3 is turned down in advance, so that the water accumulated in the bottom of the barrel body 1 and the sewage pipe 3 Dirt forms a naturally flowing pre-discharge. Thus, after the pressing part triggers the drain switch 8, the water gushing out from the water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com