Novel background wall and installation method thereof

An installation method and background wall technology, applied in the field of background walls, can solve the problems of no thermal insulation, waterproof and fire prevention, poor decorative effect of thermal insulation, inconvenient transportation and installation, etc., so as to increase thermal insulation performance and facilitate transportation and installation , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

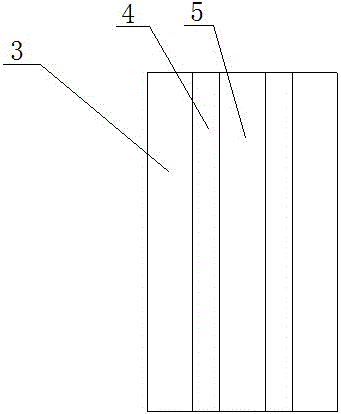

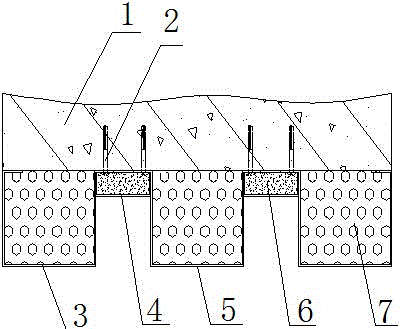

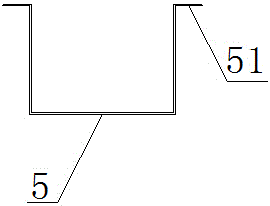

[0027] Such as figure 1 , figure 2 As shown, the present invention discloses a new type of background wall, including a base body 1, a raised module 5, a groove module 4 and an expansion nail 2; the groove module 4 is arranged between two raised modules 5, and the raised module 5 passes through The expansion nail 2 is connected to the base 1; and the protrusion module 5 and the groove module 4 are arranged on the base 1 parallel to each other. Such as image 3 As shown, the protruding module 5 is a long straight groove made of a composite plate, and its two sides in the length direction are symmetrically provided with an outer flange A51 that is bent outward and is convenient for connecting with the base body 1; There are several connection holes A for the installation of expansion nails 2; the groove module 4 is a long straight groove made of a composite plate, and the groove module is buckled between two protruding modules 5, and its bottom surface is filled with Gypsum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com