Three-section type screw rotor and twin-screw vacuum pump comprising same

A three-stage, rotor technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the weak ability of leakage and backflow between stages, low utilization rate of cross-sectional line area, large leakage and backflow between stages, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and embodiments.

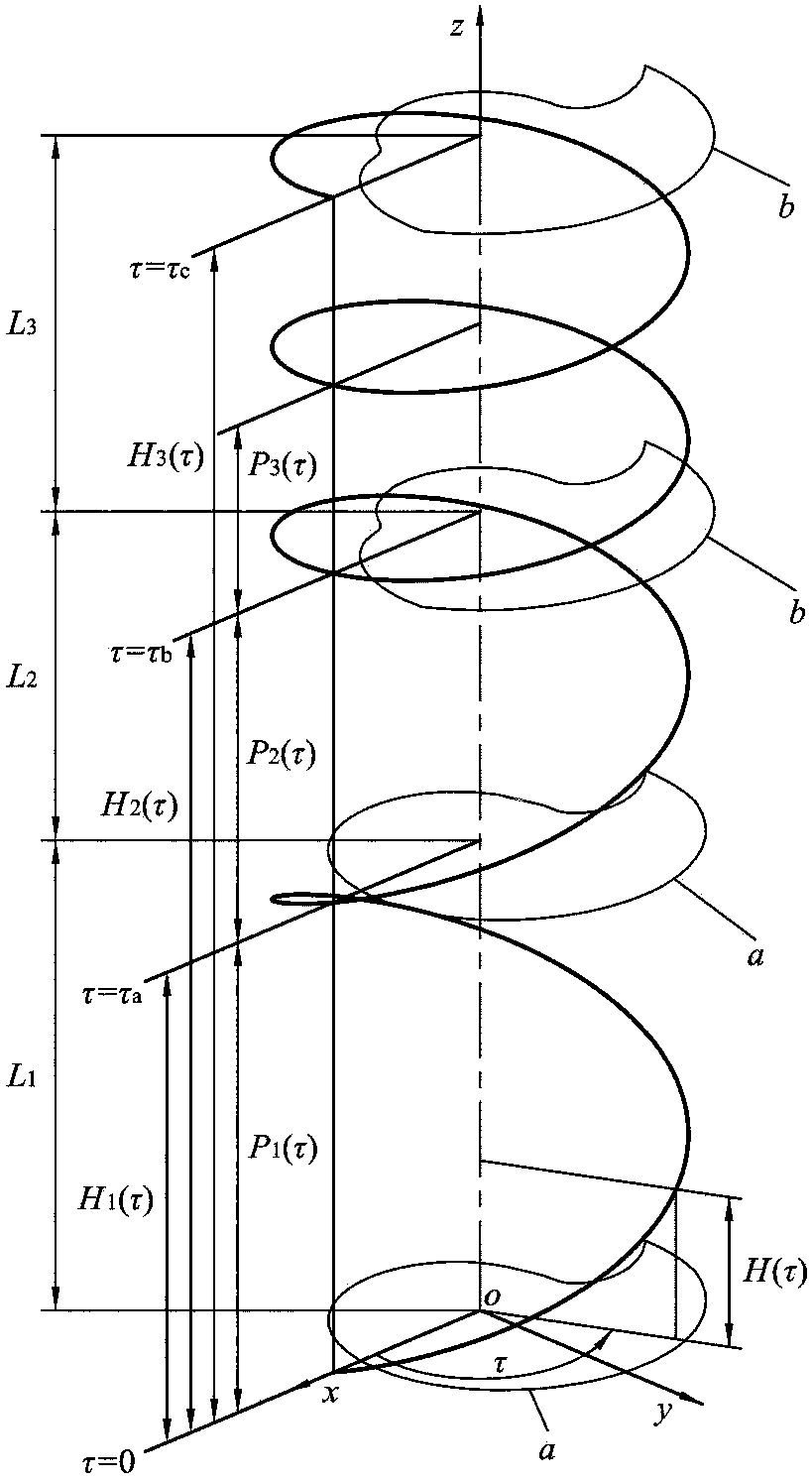

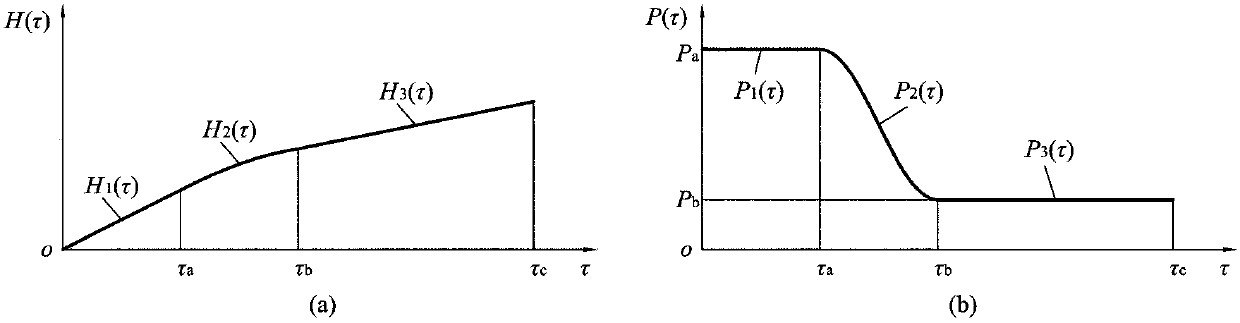

[0038] Such as figure 1 Shown is the cross-sectional profile and axial distance diagram of the three-section screw rotor. The three-section screw rotor consists of the suction section L 1 , Compression section L 2 And exhaust section L 3 Composition, suction section L 1 , Compression section L 2 And exhaust section L 3 The range of the spiral expansion angle τ is 0≤τ≤τ a , Τ a ≤τ≤τ b And τ b ≤τ≤τ c ; Inspiratory section L 1 And exhaust section L 3 Is equal pitch, suction section L 1 And exhaust section L 3 Compressed section L between 2 Transition, compression section L 2 It is a variable pitch; the formula of the axial distance H(τ) and the pitch P(τ) of the screw rotor is as follows:

[0039] H ( τ ) = H 1 ( τ ) , 0 ≤ τ ≤ τ a H 2 ( τ ) , τ a ≤ τ ≤ τ b H 3 ( τ ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com