Bag-type dust remover AC and DC matrix control circuit

A bag filter and matrix control technology, applied in the direction of converting AC power input to DC power output, irreversible AC power input converting to DC power output, and no intermediate conversion to AC conversion equipment, etc., can solve the problem that the matrix circuit cannot be used. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

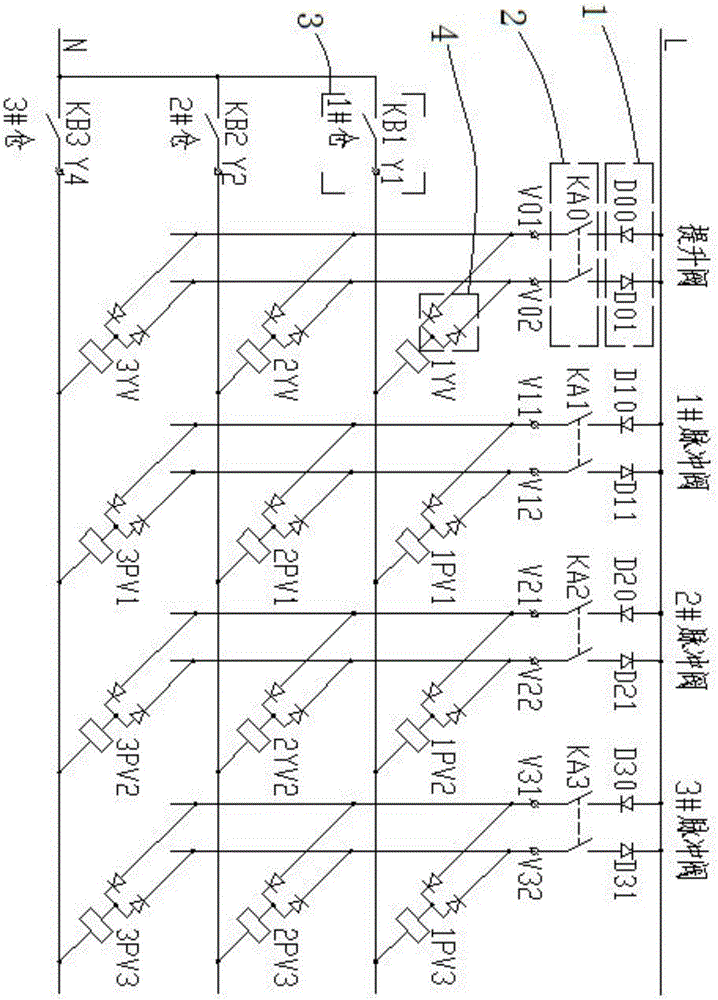

[0021] An AC and DC matrix control circuit for bag filter, see figure 1 ,against figure 1 The control principles are described as follows:

[0022] figure 1 It shows a bag filter. Due to the limited page width, it only shows 3 chambers, each chamber has 1 poppet valve and 3 pulse valves; no matter how many chambers there are, how many chambers are there? A poppet valve and a pulse valve have exactly the same principle;

[0023] KB1 is the relay contact controlling the 1# warehouse, KB2 is the relay contact controlling the 2# warehouse, and KB3 is the relay contact controlling the 3# warehouse;

[0024] KA0 is the relay contact controlling the poppet valve in each chamber, KA1 is the relay contact controlling the 1# pulse valve in each chamber, KA2 is the relay contact controlling the 2# pulse valve in each chamber, KA3 is the relay contact controlling each The relay contact of the 3# pulse valve in each chamber;

[0025] 1YV is the poppet valve coil of 1# chamber, 2YV is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com