Compact moving-iron telephone receiver,

A receiver, compact technology, applied in the direction of sensors, electrical components, etc., can solve problems such as troublesome application of end customers, achieve the effect of improving low-frequency sensitivity, reducing low-frequency distortion, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

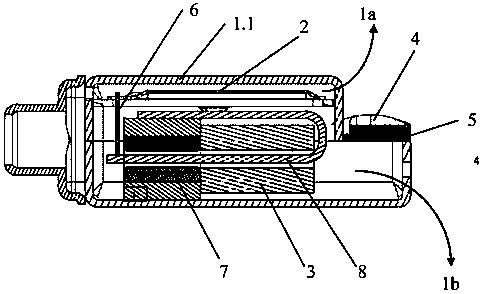

[0023] Such as figure 1 , 2 As shown, a compact moving iron receiver includes an electromagnetic shielding shell 1, a diaphragm 2, a coil 3, a PCB board 4, a connecting rod 6, a magnet 7, and a tongue 8. The electromagnetic shielding shell 1 is buckled together The upper cover 1.1 and the lower cover 1.2 are composed. The diaphragm 2 is fixed in the upper cover 1.1. The internal space of the electromagnetic shielding shell is divided into a front cavity 1a and a rear cavity 1b. The space formed between the diaphragm 2 and the top plate of the upper cover is the front cavity 1a The remaining space inside the electromagnetic shielding shell is the rear cavity 1b, the coil 3, the magnet 7, and the tongue reed 8 are arranged in the rear cavity 1b. One end of the connecting rod 6 is fixed at the end of the tongue 8 and the other end is connected to the diaphragm 2.

[0024] The width of the upper cover 1.1 and the lower cover 1.2 are the same. The front end of the upper cover 1.1 and t...

Embodiment 2

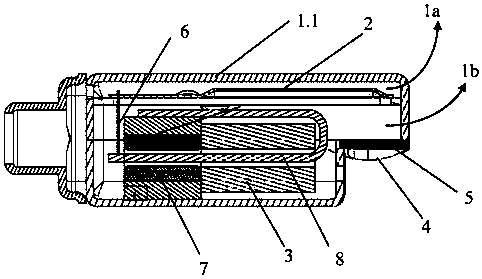

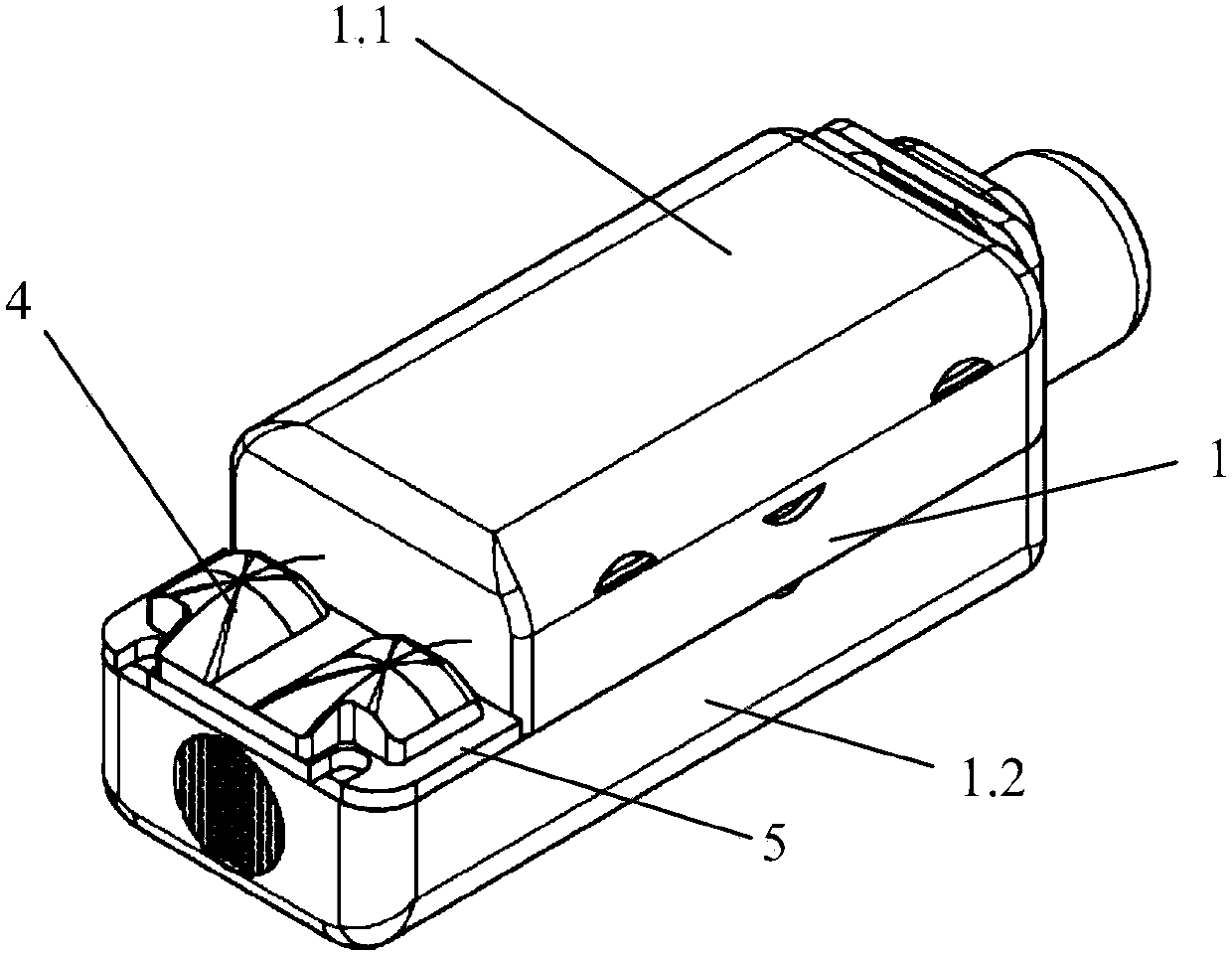

[0027] Such as image 3 , 4 As shown, a compact moving iron receiver includes an electromagnetic shielding shell 1, a diaphragm 2, a coil 3, a PCB board 4, a connecting rod 6, a magnet 7, and a tongue 8. The electromagnetic shielding shell 1 is buckled together The upper cover 1.1 and the lower cover 1.2 are composed. The diaphragm 2 is fixed in the upper cover 1.1. The internal space of the electromagnetic shielding shell is divided into a front cavity 1a and a rear cavity 1b. The space formed between the diaphragm 2 and the top plate of the upper cover is the front cavity 1a The remaining space inside the electromagnetic shielding shell is the rear cavity 1b, the coil 3, the magnet 7, and the tongue reed 8 are arranged in the rear cavity 1b. One end of the connecting rod 6 is fixed at the end of the tongue 8 and the other end is connected to the diaphragm 2.

[0028] The width of the upper cover 1.1 and the lower cover 1.2 is the same, the front end of the upper cover 1.1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com