Roller system of a robot intelligent rolling hemming system

A robot intelligence, rolling hemming technology, applied in the field of roller system, can solve problems such as the influence of hemming angle, stacking quality, poor quality, etc., to achieve the effect of solving the wrinkling of stacking materials and ensuring the quality of hemming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

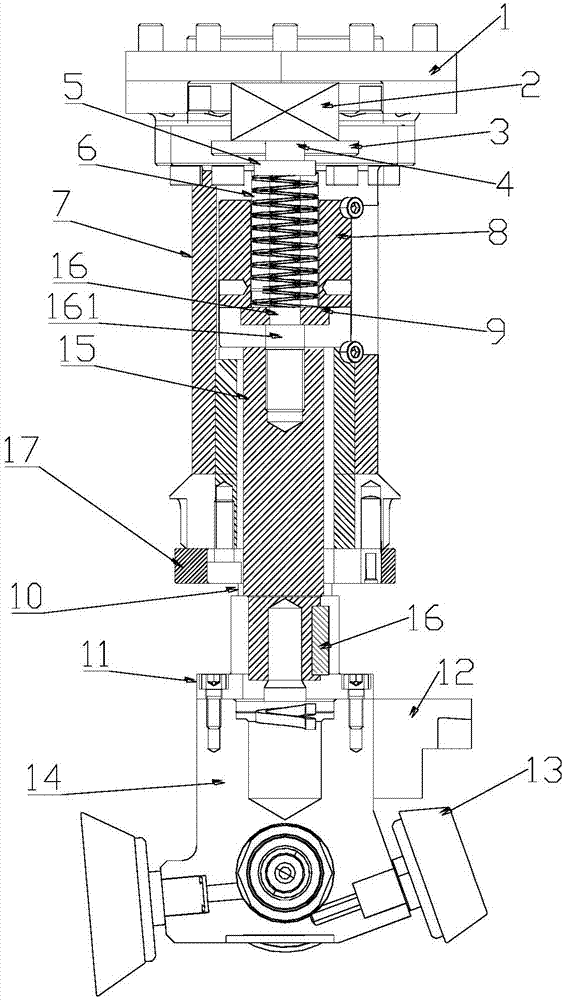

[0020] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

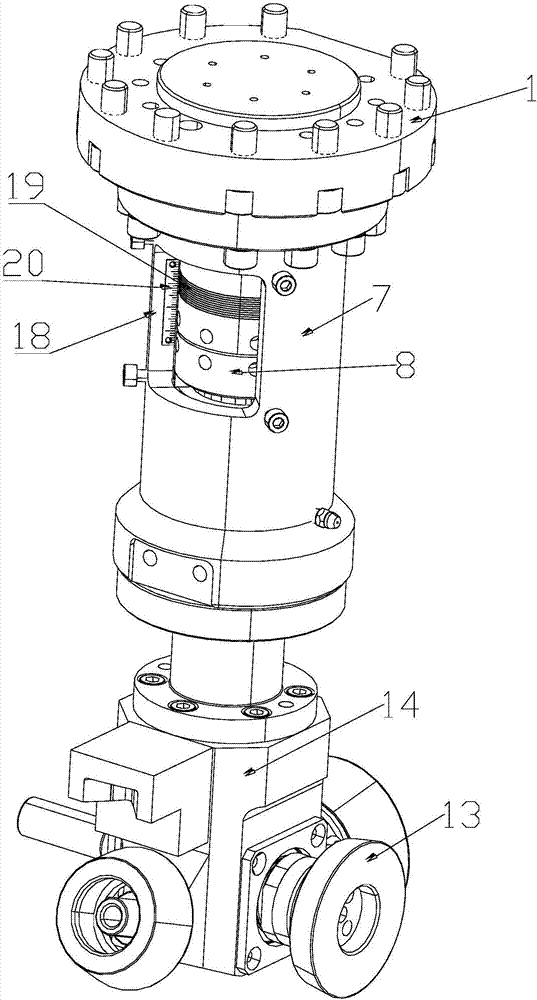

[0021] Such as figure 1 , figure 2 As shown, a roller system of a robot intelligent rolling hemming system includes a robot connecting flange 1, the lower end of the robot connecting flange 1 is connected with a main shaft 7, the end of the main shaft 7 is equipped with a roller head 14, and the roller head 14 is equipped with several Roller 13, the inside of the main shaft 7 is provided with a cylindrical cavity, a pressure sensor 2 is installed near the end of the cavity connecting the flange 1 of the robot, and an annular end cover 3 is installed below the pressure sensor 2, and the annular end cover 3 connects the pressure sensor 2. Compress and fix. The lower end of the pressure sensor 2 is equipped with a pressure sensing pressure head 4. The pressure sensing pressure head 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com