Twin-roller type aluminum alloy roller press

An aluminum alloy, double-roller technology, applied in the field of rolling machines, achieves the effect of improving product quality, good processing stability, and reducing relative motion and friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

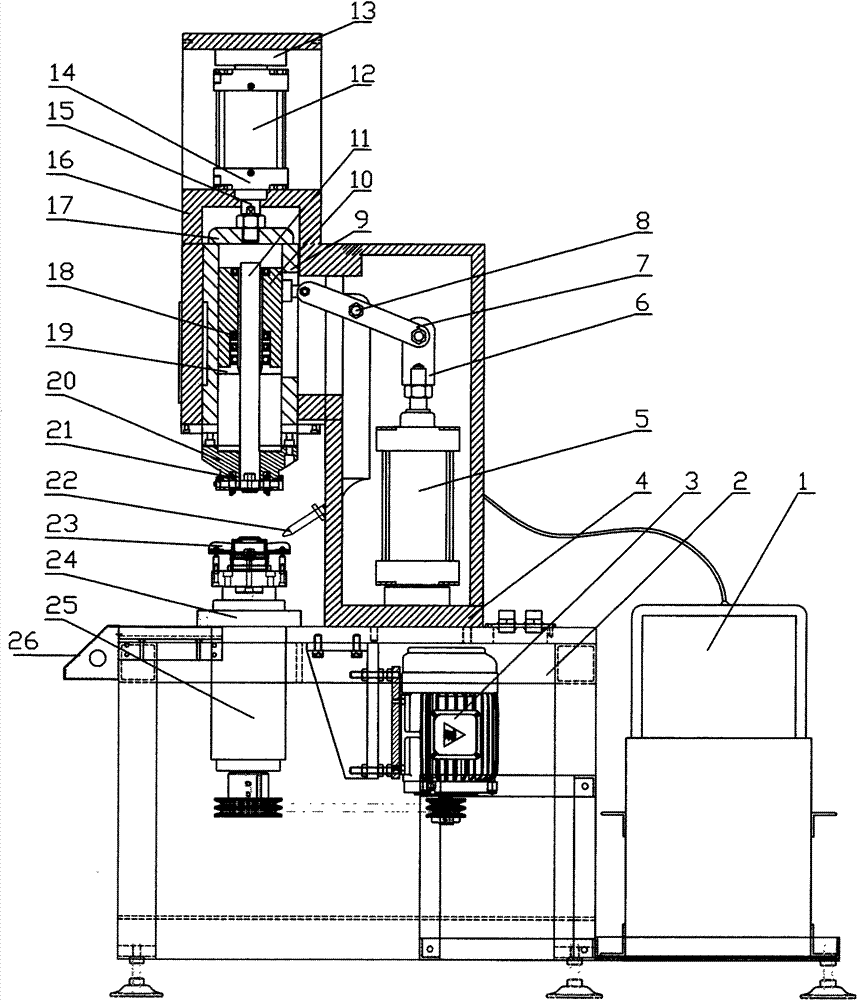

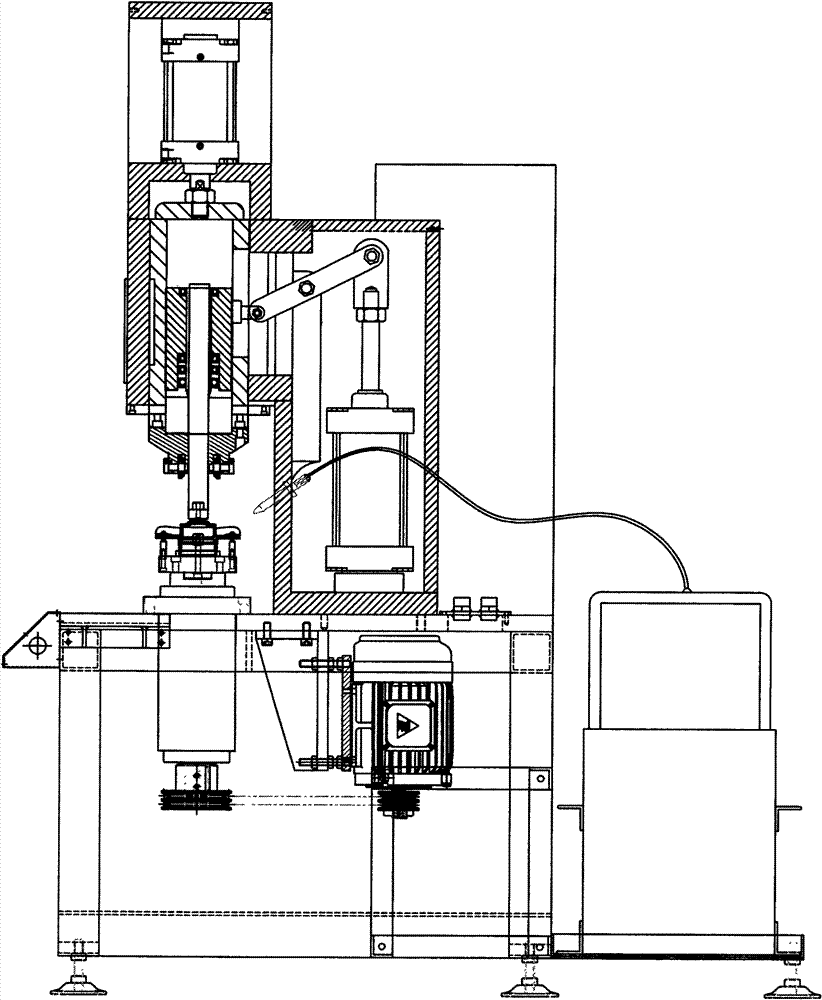

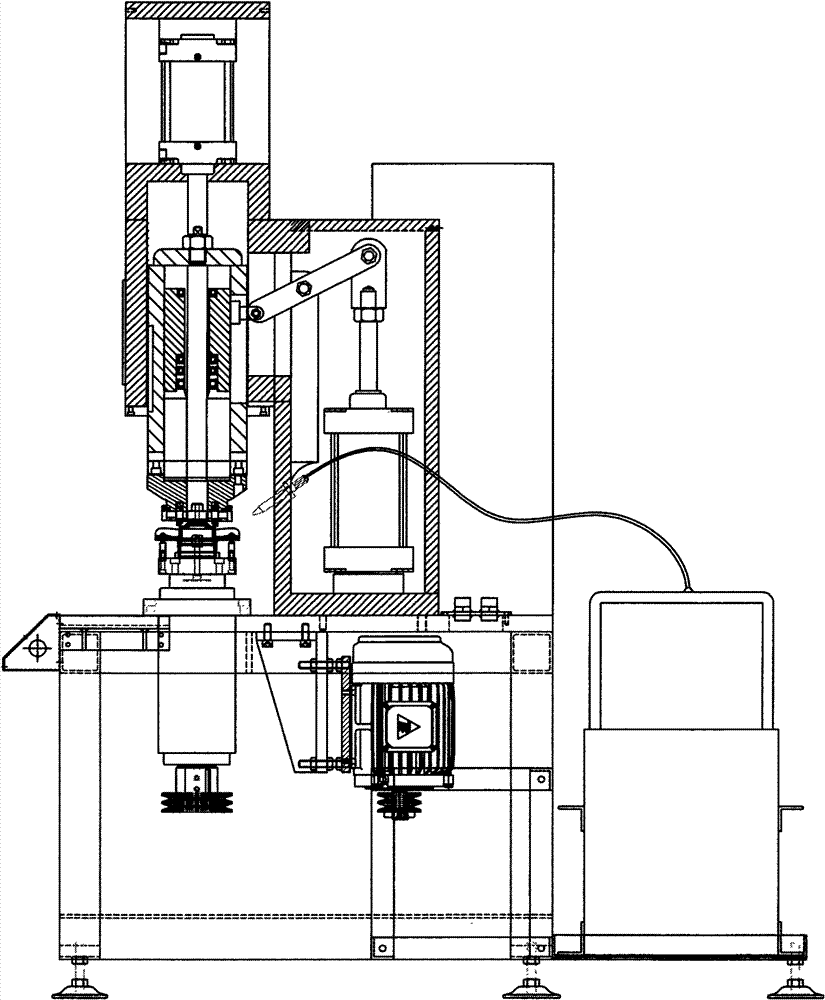

[0015] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

[0016] The rotating base 24 and the motor 3 are respectively fixed on the upper and lower surfaces of the frame 2 with screws. The motor 3 is connected to the main shaft 25 through a belt, and the main shaft is connected to the workpiece 23 through the through hole in the middle of the rotating base 24. The cylinder base 4 is fixed with screws, the rolling cylinder 5 is fixed on the cylinder base 4 with screws, one end of the piston rod 6 on the upper end of the rolling cylinder is fixedly connected with the lower end of the connecting rod 7, and the upper end of the connecting rod 7 passes through the side of the cylinder base 4 The gap on the upper part is fixed at the boss on the side wall of the sliding body 10, the pin shaft 8 passes through the through hole in the middle of the connecting rod, and the connecting rod 7 is movably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com