A construction method of pvc piping for the inlet and outlet lines of the distribution box at the bottom of the beam

A construction method and power distribution box technology, which are applied in the processing of building materials, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the difficulty of fixing PVC lug joints, the low turnover life of formwork, piping Large damage and other problems, to reduce the difficulty of fixing and piping connection, easy to ensure quality, and ensure the effect of piping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] (1), integrated module processing and production:

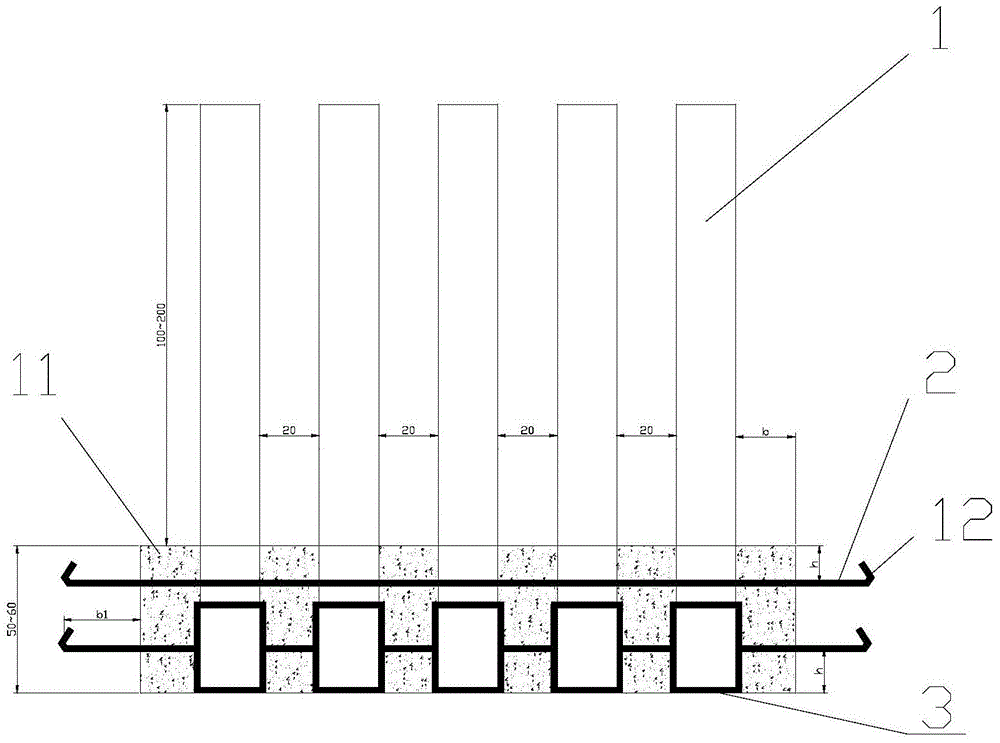

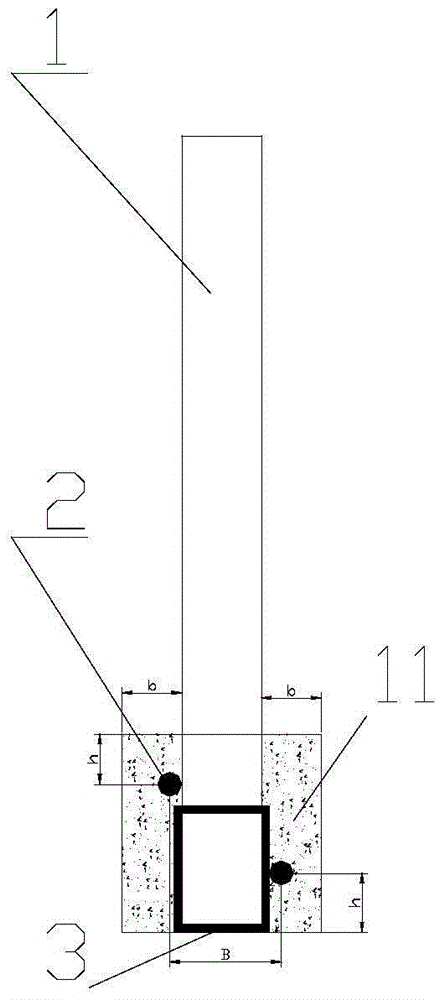

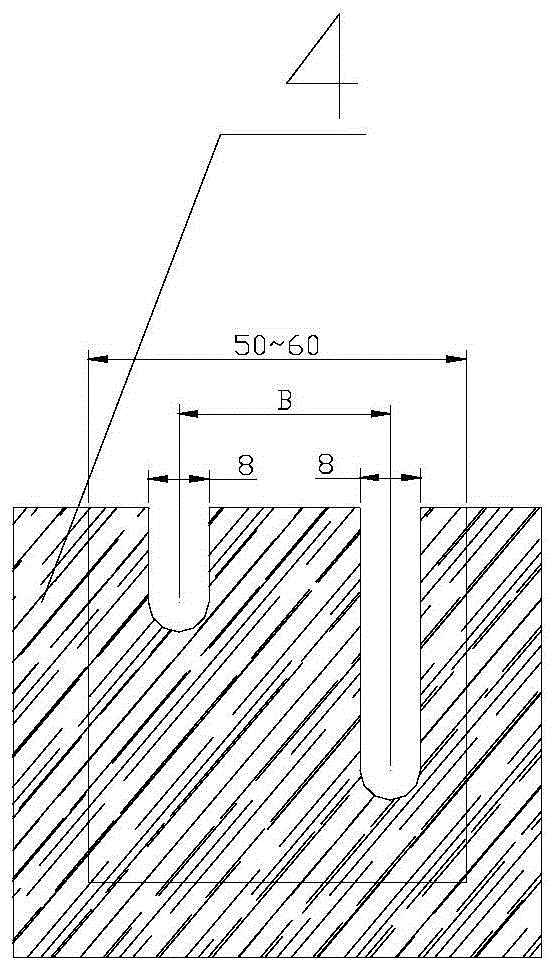

[0022] see figure 1 , figure 2 and image 3 , according to the design of the PVC pipes in and out of the distribution box, design the size and processing mold of the integrated module of the PVC pipe joints, and according to the quantity and specification of the reserved PVC pipes 1, the distance between the reserved PVC pipes 1 is 15mm-25mm, preferably 20mm , one end of the reserved PVC pipe 1 has been installed with prefabricated PVC joint 3 with PVC special glue; between multiple reserved PVC pipes 1, two Φ6 threaded steel bars 2 and binding wires are used to fix the position, reserved PVC pipe 1, prefabricated The PVC joint 3 and the threaded steel bar 2 are integrated into the wooden mold 4, the two ends of the Φ6 threaded steel bar 2 exceed the mold by 20 mm to 40 mm (b1), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com