Feeding and discharging mechanical arm of thermal forming press

A thermoforming and manipulator technology, applied in the field of manipulators, can solve the problems of affecting the punching beat of the press, the high cost of using robots, and the low utilization rate of robot performance, so as to reduce costs and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

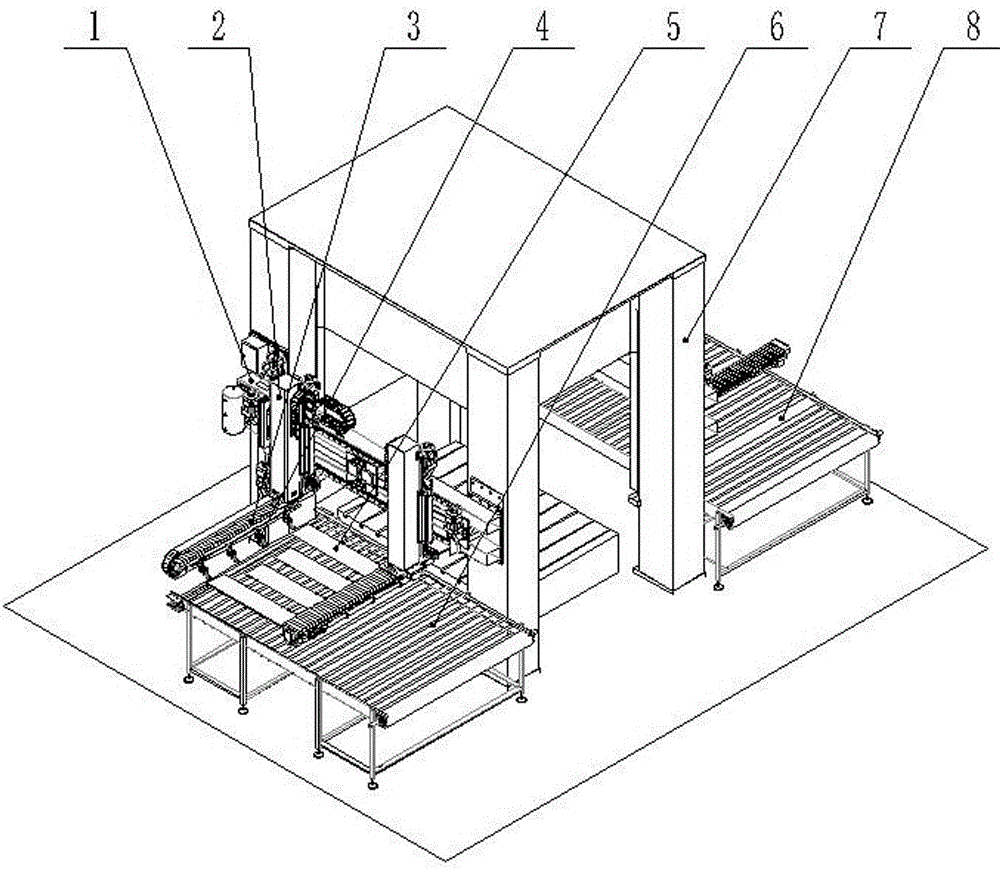

[0021] Attached below figure 1 to attach Figure 5 The present invention will be further described.

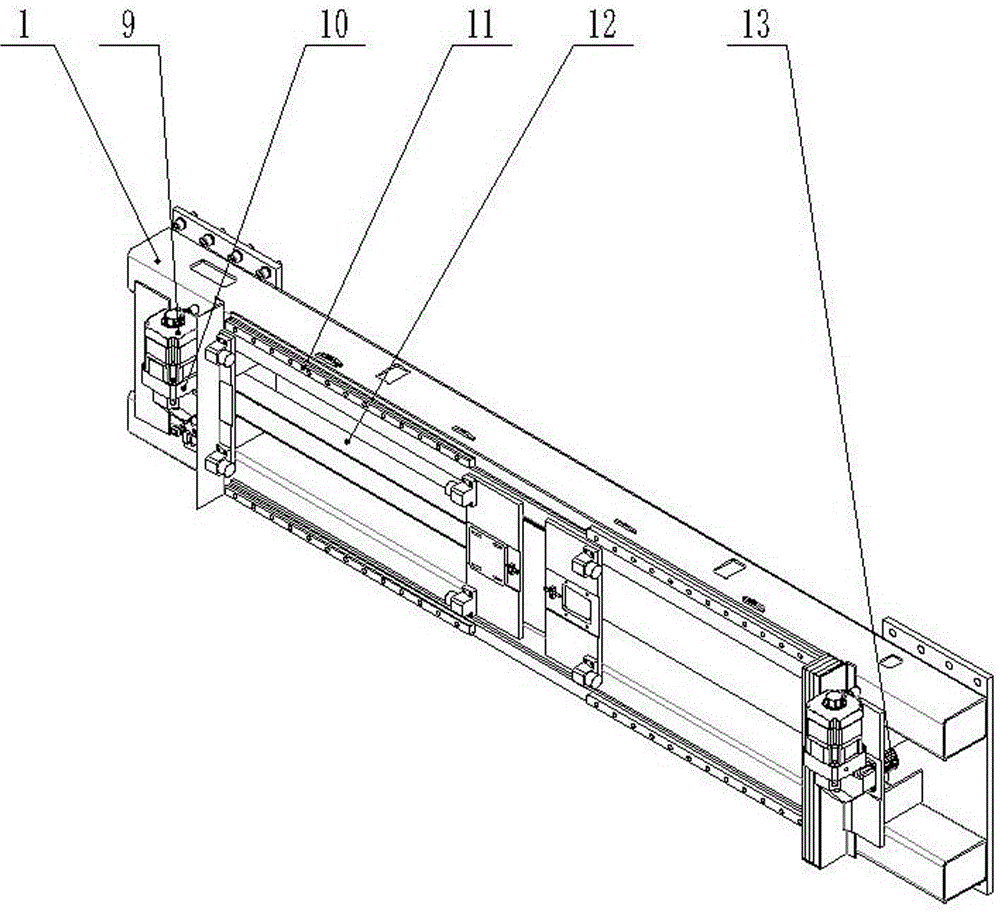

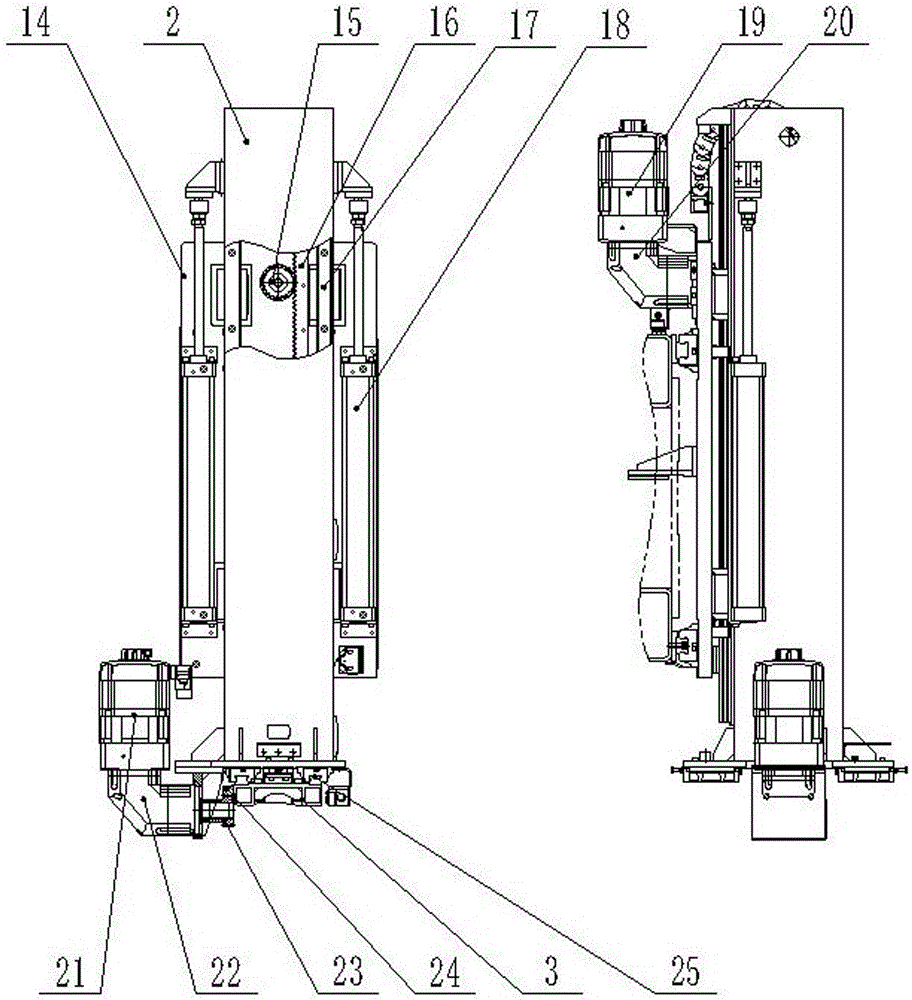

[0022] A loading and unloading manipulator for a thermoforming press, comprising: a crossbeam 1 horizontally installed on the feed side and discharge side of the press 7 respectively, horizontally slid and installed on the crossbeam 1 in the left and right direction through the guide rail I 11 fixed on the crossbeam 1 The supporting plate 14, the lifting arm 2 installed on the supporting plate 14 by sliding vertically through the guide rail II 17 fixed on the lifting arm 2, and the lifting arm 2 installed on the lifting arm horizontally sliding in the front and rear direction through the guide rail III 25 fixed on the lower end of the lifting arm 2 2 The shuttle arm 3 at the lower end and the end picker 4 arranged at the lower end of the shuttle arm 3 for clamping the workpiece 5 on the loading table 6 or the unloading table 8, and the beam 1 is provided with a drive plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com