A self-healing multifunctional composite structure

A composite material and multi-functional technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of sacrificing structural weight and efficiency, low load-bearing stress level, etc., to increase the ability of impact damage resistance and The effects of anti-fatigue delamination expansion ability, recovery bearing capacity, increase in interlaminar fracture toughness and anti-delamination generation and expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

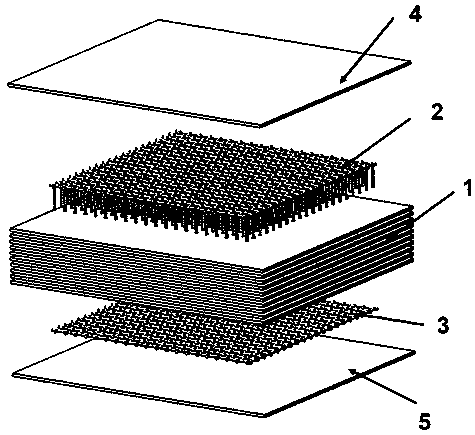

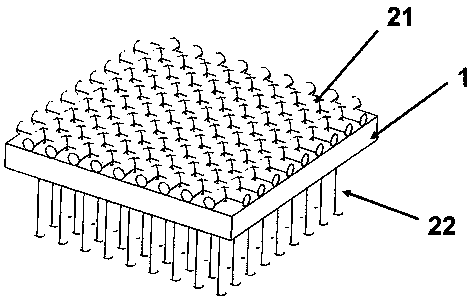

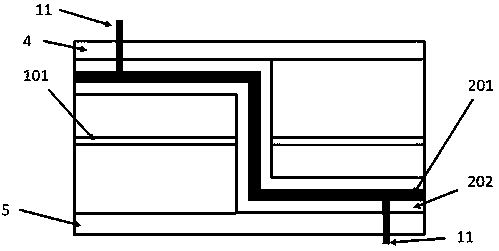

[0027] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a composite material main body 1, the upper surface of the composite material main body 1 is coated with a three-dimensional metal network 2, the lower surface is coated with a planar metal network 3, and the upper surface of the three-dimensional metal network 2 is coated with a composite material upper cover plate 4. The lower surface of the planar metal network 3 is coated with a composite material lower cover plate 5; the top of the three-dimensional metal network 2 is a planar interwoven metal mesh 21, and the metal mesh 21 extends in the vertical direction with a metal wire 22 connected to it; The metal wire 22 of the three-dimensional metal network 2 runs through the composite material main body 1 and is connected with the planar metal network 3 at the bottom; the surfaces of the three-dimensional metal network 2 and the planar metal network 3 are coated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com