Cigarette missing detector

A technology for detectors and cigarettes, which is applied in the directions of automatic packaging control, packaging, and packaging protection. It can solve the problems of long debugging time, production progress, increased production costs, and consumption of large cigarettes, so as to achieve low use and maintenance costs and increase Reliability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

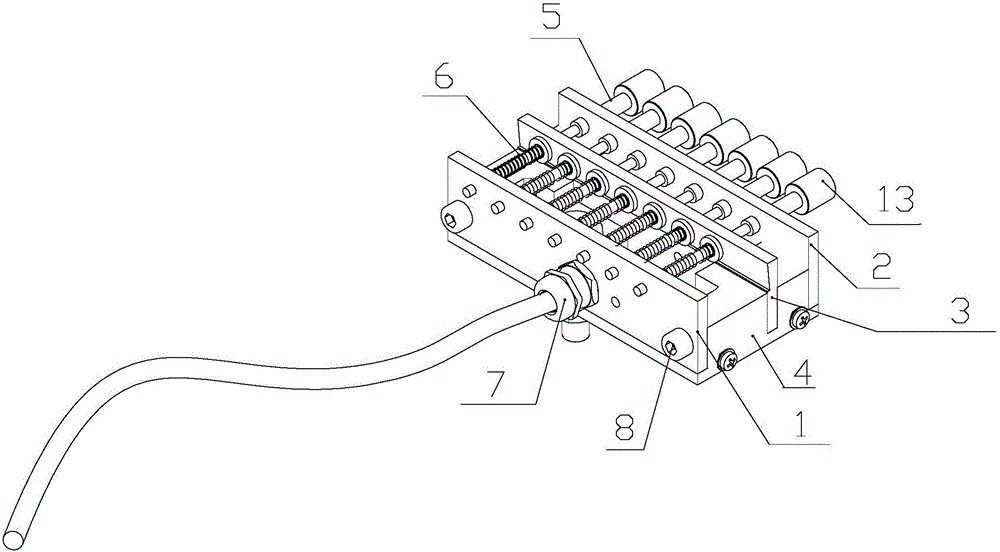

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0024] see Figure 1-7 :

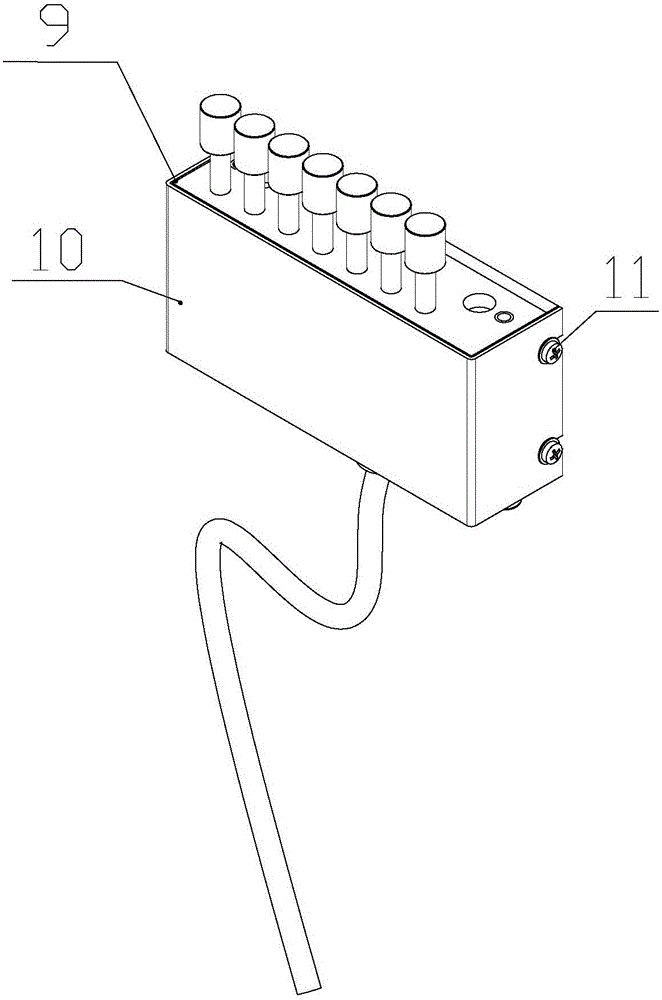

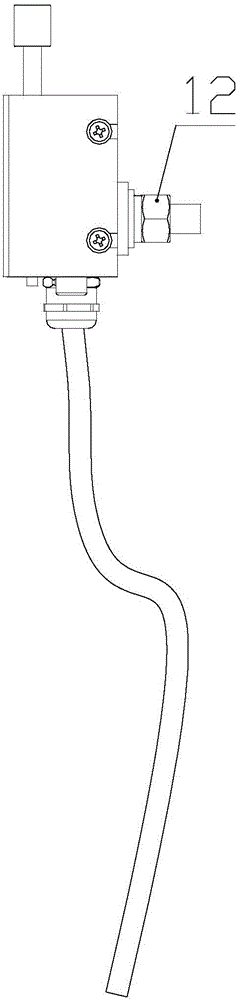

[0025] The cigarette holder provided by the present invention adopts the following technical scheme: the lack of a detector for the cigarette is composed of a connector board 1 (cr12 signal connection terminal A), a main baffle 2 (cr12), a copper middle board 3 (H62), Base 4, guide rod body 5, compression spring 6, signal line connection port 7, adjusting bolt 8, insulating paper 9, shell 10 (LY12), M3 fastening bolt 11, M8 mounting bolt 12.

[0026] The connector board 1 is connected to the signal line A end, and the copper middle plate 3 is connected to the signal line B end to form the signal output AB end. The signal line connection port 7 is installed on the connector plate 1, the compression spring 6 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com