A low-carbon hydrocarbon fluidized bed aromatization device and its application

A carbon-hydrocarbon fluidized bed and aromatization reactor technology, which is applied in organic chemistry, hydrocarbon production from oxygen-containing organic compounds, and condensation hydrocarbon production with dehydrogenated hydrocarbons, etc., can solve problems such as poor economy and achieve production Low cost, reduced circulation, and the effect of facilitating the balanced utilization of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] ZSM-5 molecular sieve, kaolin, and aluminum sol are formulated into a mixed slurry, and composite particles are obtained by spray granulation. The prepared composite particles are roasted in a horse boiling furnace at a specific temperature. The active metal mixed solution and the calcined composite particles are stirred, impregnated and dried, and then calcined at a specific temperature for several hours to obtain the final catalyst, which is a special catalyst for aromatization.

Embodiment 2

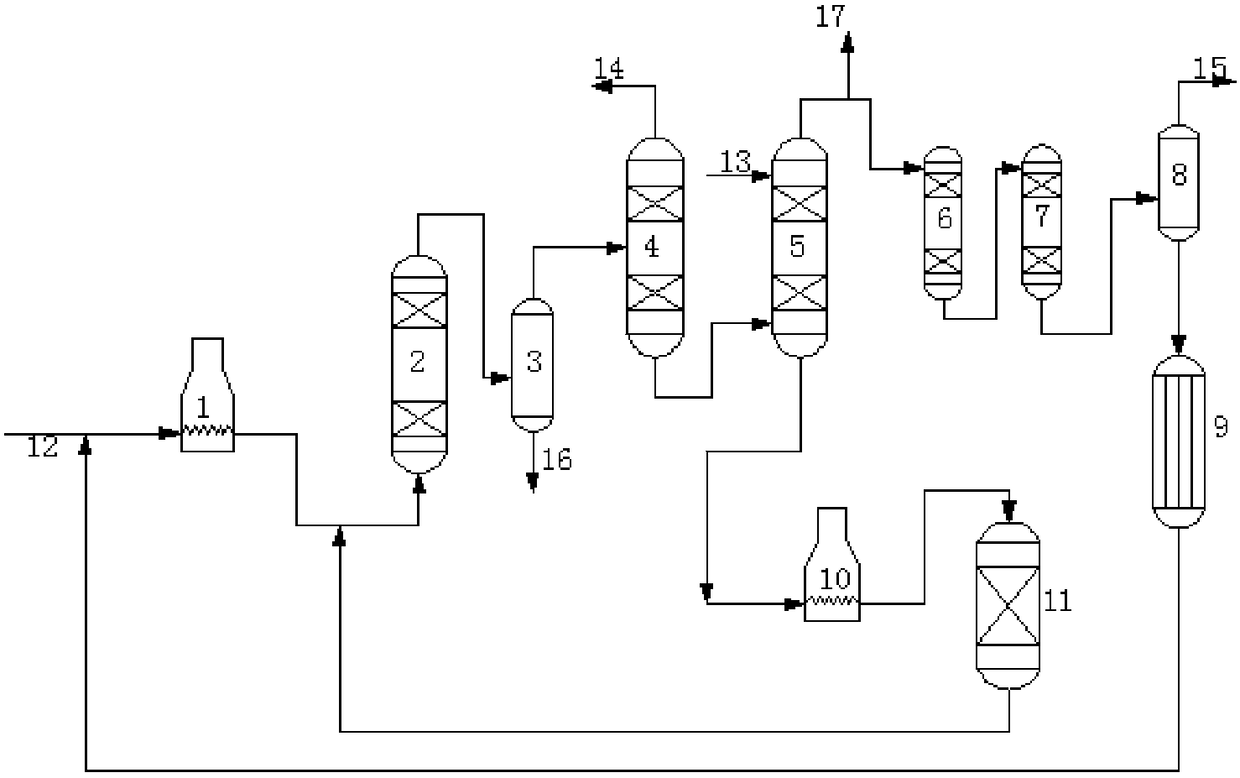

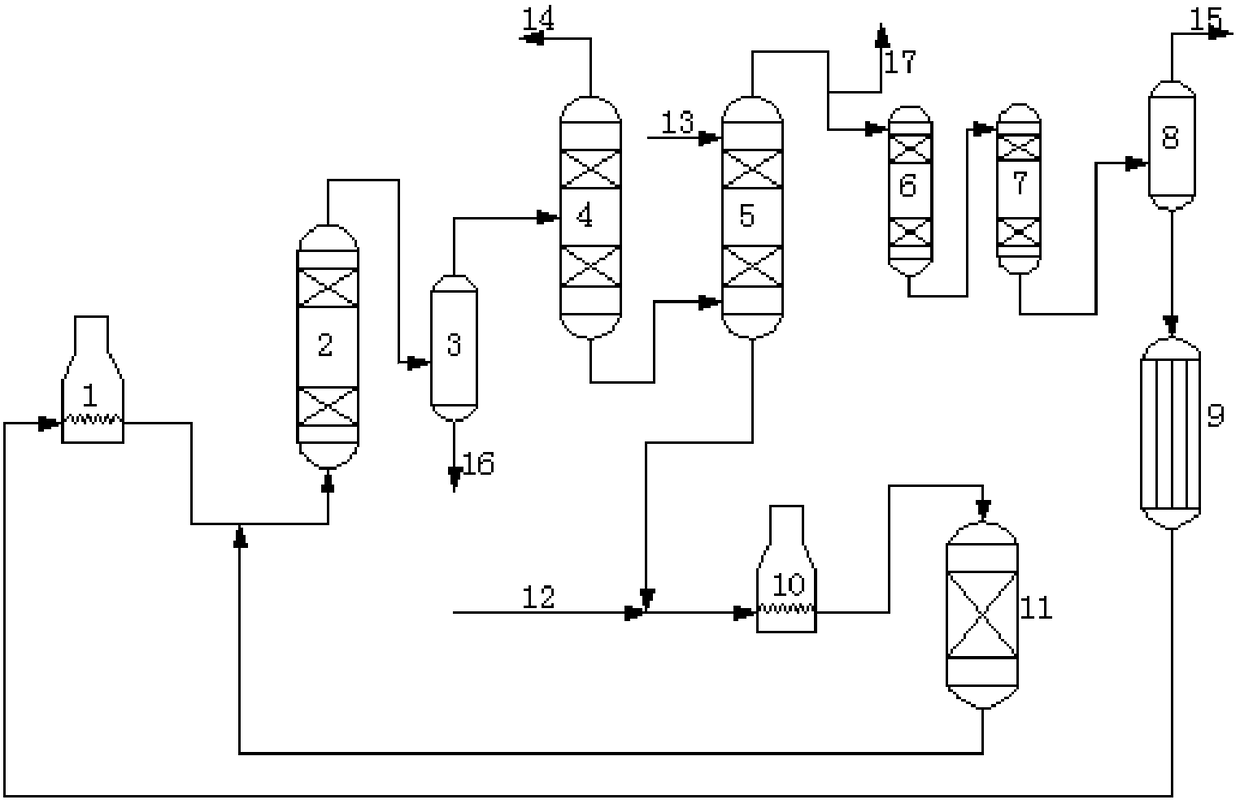

[0034] Weigh 880 g of the catalyst obtained in Example 1 and put it into the fluidized bed aromatization reactor 2 .

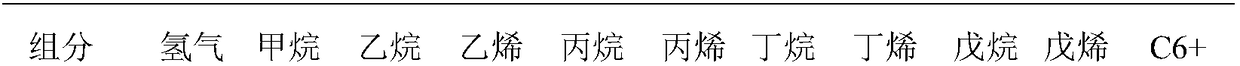

[0035] The mixed low-carbon hydrocarbons 12 with the composition and content shown in Table 1 enter the fluidized bed aromatization reactor 2 after being preheated by the raw material preheating furnace 1 to undergo aromatization reaction, and are separated by the aromatic hydrocarbon gas-liquid separator 3 to obtain The liquid phase is the aromatic product 16, and the obtained gas phase enters the pressure swing adsorption separator 4, where the hydrogen gas 14 is separated by adsorption, and the rest of the gas phase enters the absorption tower 5, and after being absorbed by the absorbent 13, it is divided into two paths, the top and the bottom. It is divided into two paths again, and the path containing only methane passes through the methane conversion reactor 6 and the methanol synthesis tower 7 to obtain a mixture containing methanol and non-condensable g...

Embodiment 3

[0039] The reaction temperature of whole device is 475 ℃, and others are all identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap