A kind of graphene oxide composite non-woven fabric and its preparation method and application

A graphene composite, non-woven technology, applied in textiles and papermaking, electrical components, circuits, etc., can solve problems such as poor electronic and ionic conductivity, low conductivity, and reduced ionic conductivity, and prevent micro-short circuits. , the effect of reducing the size and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

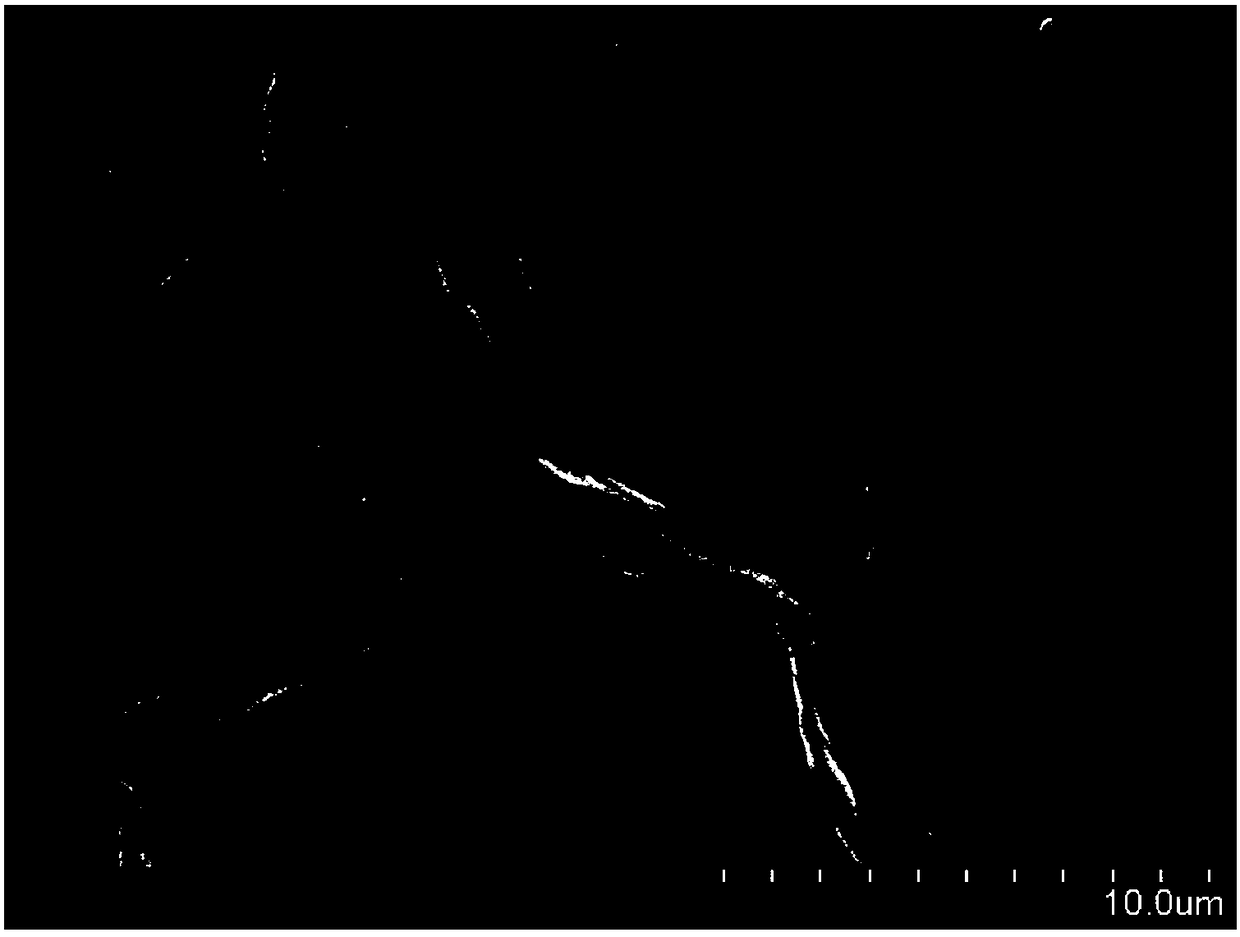

[0039] Put 1 g of graphene oxide into 20 g of a mixed solution of deionized water and ethanol (1:1, v:v) and stir magnetically for 5 h. Using polyvinylidene fluoride (PVDF) non-woven fabric as the base material, the obtained solution and the non-woven fabric base material are used to prepare graphene oxide composite non-woven fabric. The obtained slurry is evenly coated on one side of the PVDF nonwoven fabric, and the thickness of the coating layer is controlled at 3 μm. Preheat with an electric heating plate at 60°C, and after most of the solvent volatilizes, put it into a vacuum oven at 60°C to dry overnight to completely remove the solvent, and obtain a graphene oxide composite non-woven fabric (the graphene oxide composite non-woven fabric scanning electron microscope photo is shown in Fig. figure 1 shown).

Embodiment 2

[0041] Put 1 g of graphene oxide and 1 g of perfluorosulfonic acid resin into 50 g of a mixed solution of deionized water and ethanol (1:1, v:v) and stir magnetically for 10 h. Using polyethylene terephthalate (PET) non-woven fabric as the base material, the obtained solution and the non-woven fabric base material are used to prepare graphene oxide composite non-woven fabric. The resulting slurry is evenly poured inside the PET non-woven fabric, and the quality of the poured polymer is 5mg / cm 3 . Preheat at 60°C with an electric heating plate, wait for most of the solvent to volatilize, put it in a vacuum oven and dry at 60°C overnight to completely remove the solvent, and obtain a graphene oxide composite non-woven fabric.

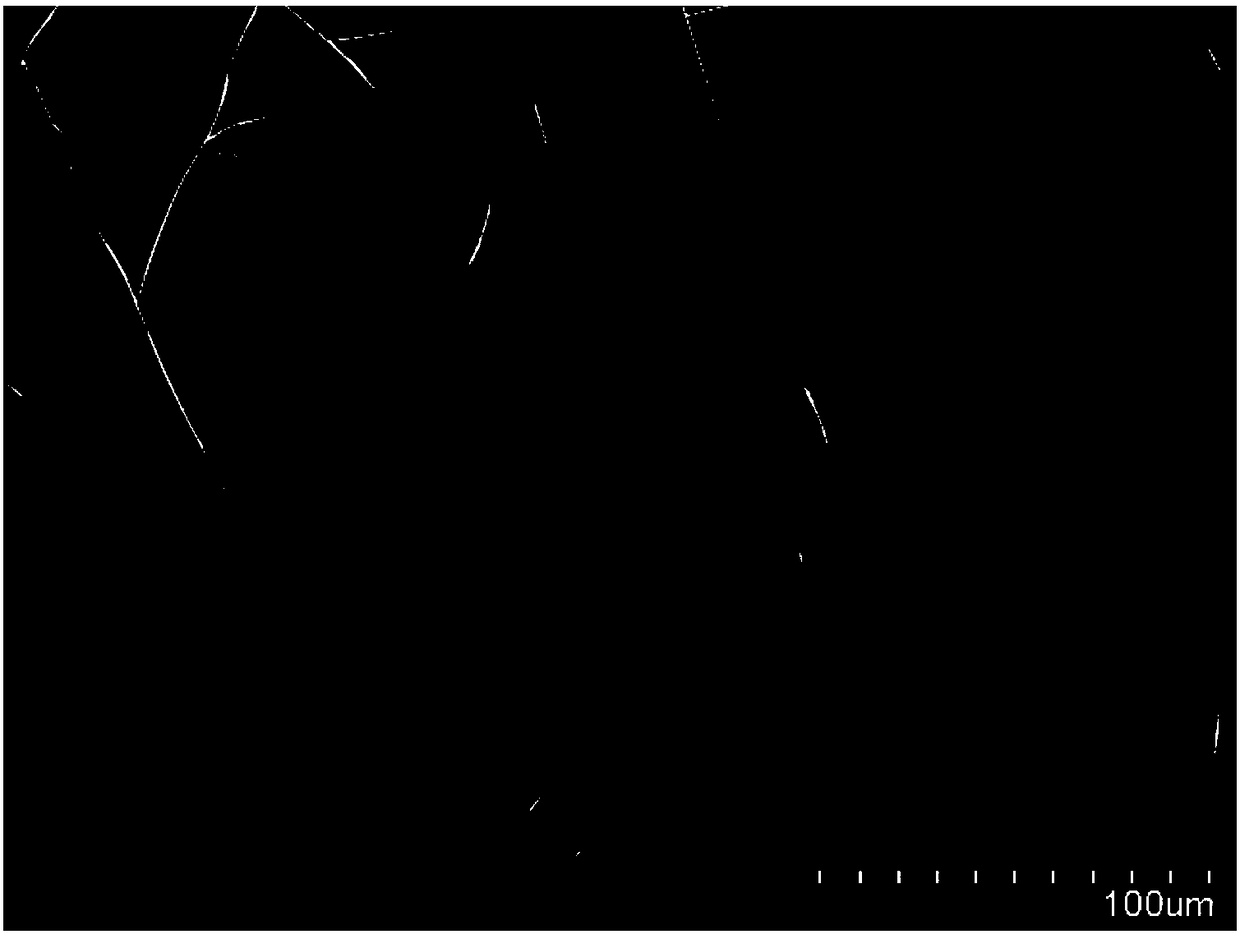

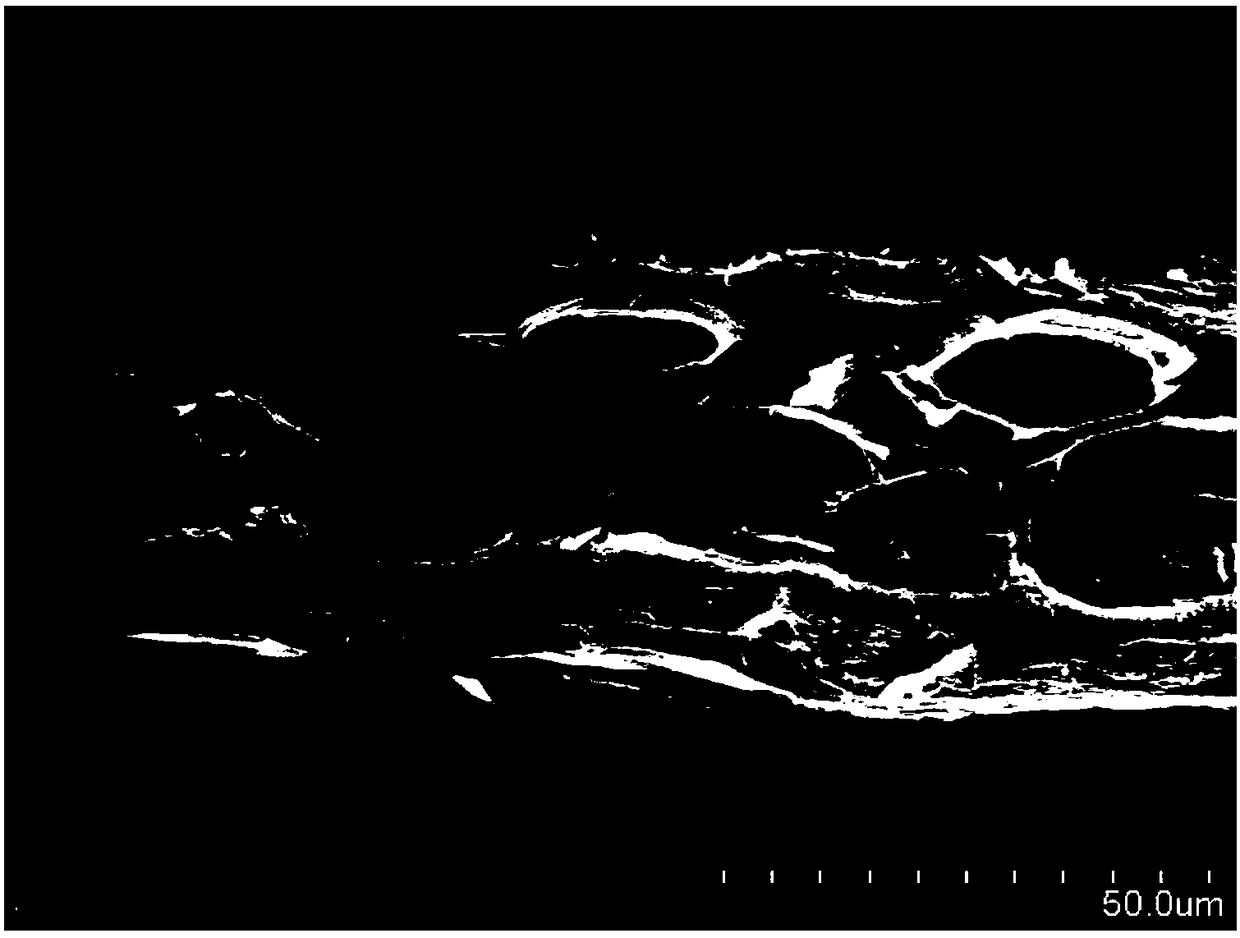

[0042] figure 2 It is the scanning electron micrograph of the surface of PET non-woven fabric. image 3 It is the scanning electron microscope image of the cross-section of the graphene oxide composite non-woven fabric.

Embodiment 3

[0044] Put 0.5 g of graphene oxide and 0.5 g of polyacrylonitrile (PAN) into 100 g of a mixed solution of nitrogen methylpyrrolidone and acetone (1:1, v:v) and magnetically stir for 20 h. The obtained solution was coated on a polyethylene terephthalate (PET) non-woven fabric as a substrate. The resulting slurry is evenly poured inside the PET non-woven fabric, and the quality of the poured polymer is 10mg / cm 3 . Preheat at 60°C with an electric heating plate, wait for most of the solvent to volatilize, put it in a vacuum oven and dry at 60°C overnight to completely remove the solvent, and obtain a graphene oxide composite non-woven fabric.

[0045] Figure 4 It is a comparison chart of graphene oxide composite non-woven fabric and ordinary PE separator to prevent the penetration of polysulfide ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com