A simple device and its operation method for realizing the rapid penetration of super-long steel tie rods

A steel tie rod and pipe threading technology, which is applied in erecting/assembling bridges, bridges, buildings, etc., can solve complex and unsafe problems, and achieve the effects of increasing pipe threading speed, improving efficacy, and improving pipe threading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

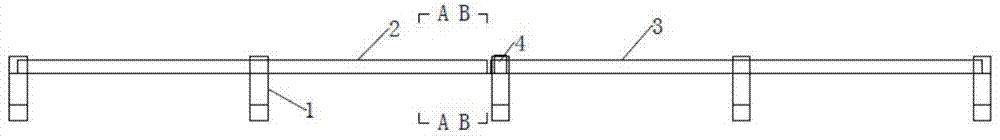

[0029] A simple device for fast threading of super-long steel tie rods. It has multiple vertically arranged pedestals 1, which are assembled with angle steel and set at intervals of 1.5m. Each pedestal is leveled with a level;

[0030] Half of the pedestal 1 is used to install a semicircular auxiliary steel pipe 2, which is connected and fixed with the pedestal 1; the length of the auxiliary steel pipe 2 is consistent with the length of the steel tie rod, and its diameter is the same size as the outer steel pipe 3 of the steel tie rod; the auxiliary steel pipe 2 is used for wearing The placement of the steel tie rod in front of the pipe, after the steel tie rod is installed with the positioning ring, it is placed in the auxiliary steel pipe 2, so that it can be smoothly sent into the steel tie rod jacket steel pipe;

[0031] The other half of the pedestal 1 is used to place the steel tie rod jacket steel pipe 3 for wearing the pipe; and a hoop 4 is set to fix the steel tie rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com