Multi-axis hinge and terminal machine using the multi-axis hinge

A hinge and machine technology, applied in the field of multi-axis hinges and tablet notebook computers using the multi-axis hinge, can solve the problems of rough appearance, large installation space, complex structure of synchronous rotation mechanism, etc., and achieve the effect of simple and neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

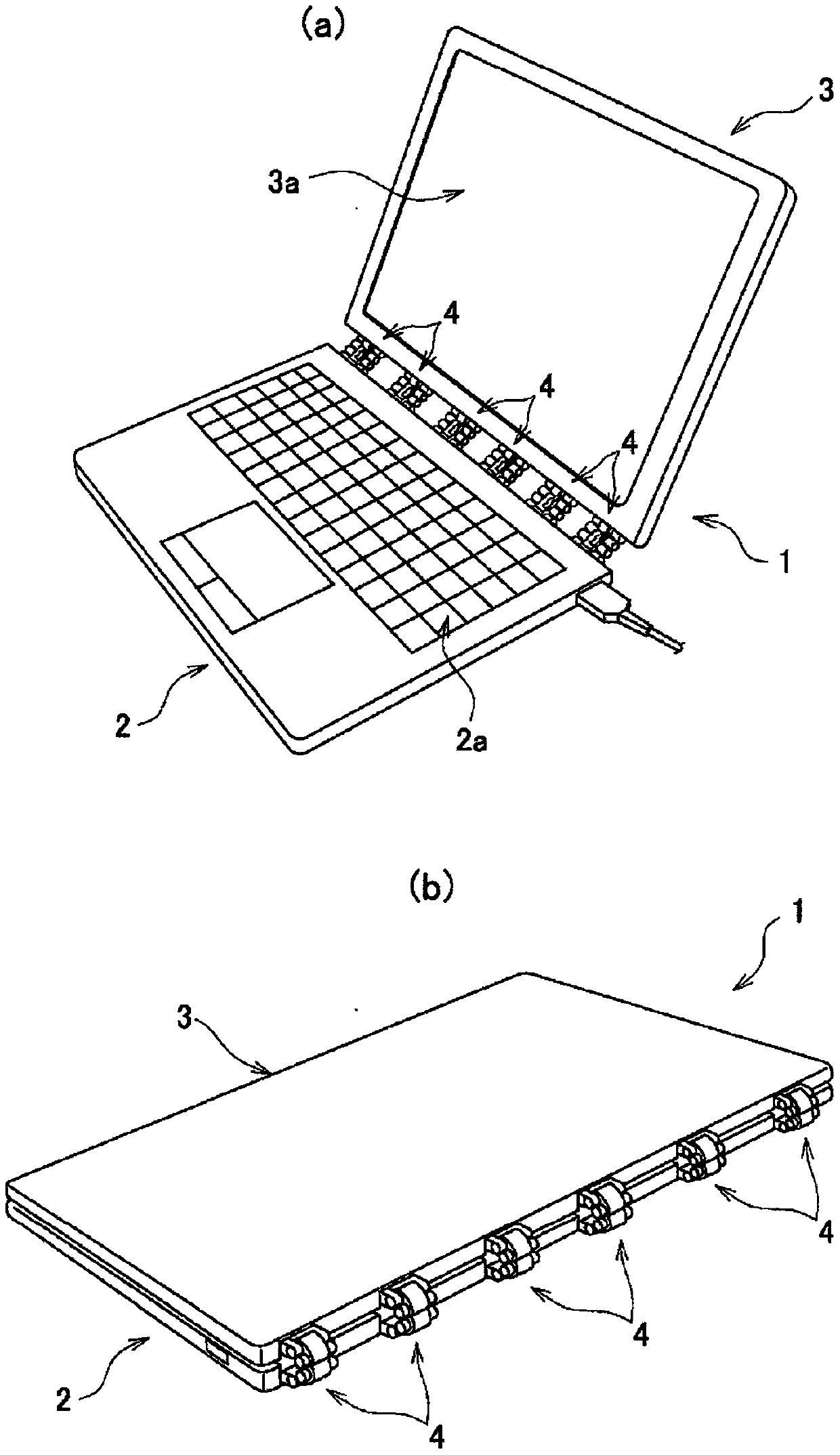

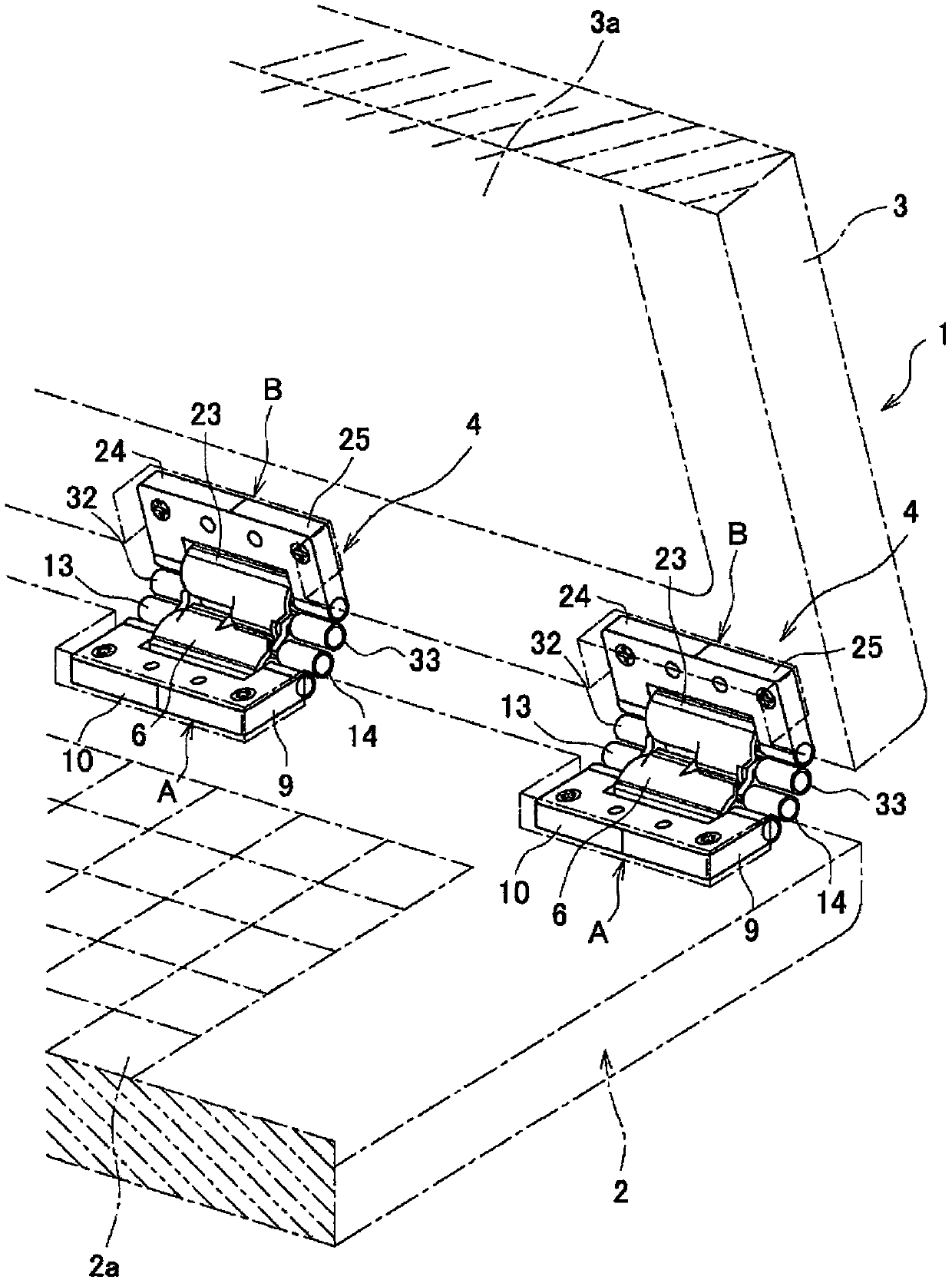

[0152] Example 1: figure 1 (a) and (b) are schematic diagrams of a notebook computer 1 using the multi-axis hinge of the present invention, and the notebook computer 1 is an example of a terminal device. The notebook computer 1 includes a first casing 2 provided with a keyboard portion 2a and a second casing 3 provided with a display portion 3a, and a plurality of multi-axis hinges 4 of the present invention can be opened and closed to connect the first casing 2 and the second casing. The rear end of the second casing 3. Although the figure shows a notebook computer using a total of six multi-axis hinges 4 as an example, the present invention does not limit the number of multi-axis hinges 4 . Only the composition of one of the multi-axis hinges 4 will be described below. In addition, other multi-axis hinges may have different configurations as long as the operation is not affected.

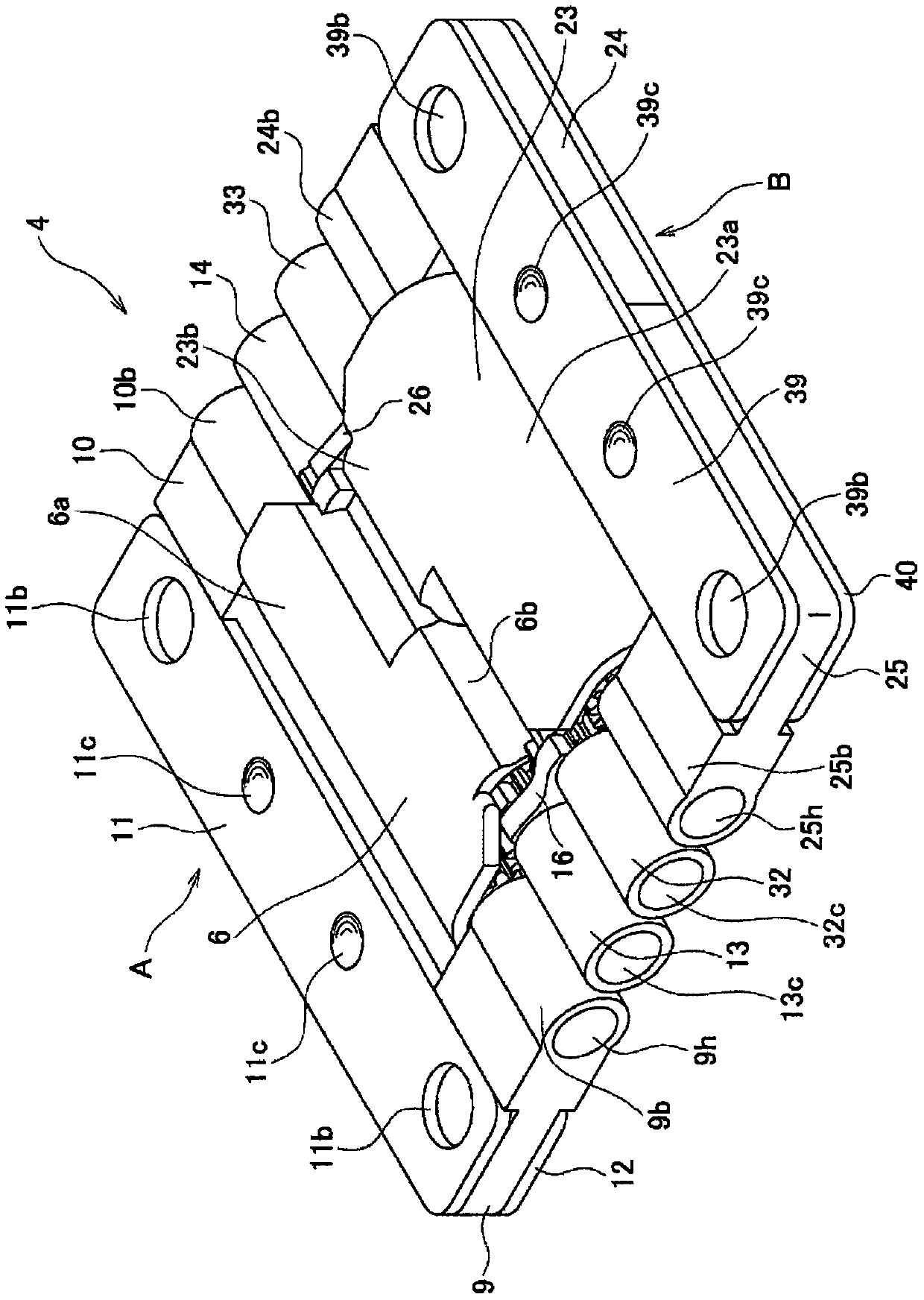

[0153] Figure 2 to Figure 18 It is a schematic diagram of a multi-axis hinge according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com