Vertical packaging machine for soft package battery

A soft-pack battery and packaging machine technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problem of the difficulty in guaranteeing the service life and reliability of soft-pack batteries and affecting the quality of finished batteries. , affecting the quality of finished battery products, etc., to achieve the effect of rapid action, high degree of automation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

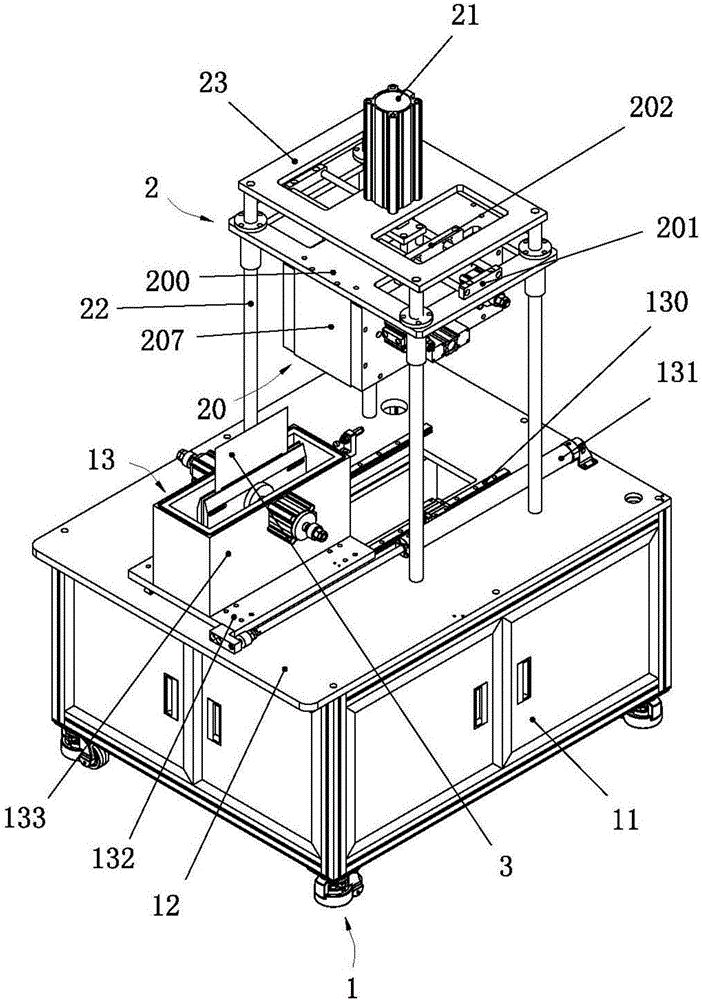

[0023] The invention is used for secondary packaging of the pouch battery that has undergone the pre-sealing process, vacuumizes and encapsulates the pouch battery that has undergone the pre-sealing process in an upright state, and separates and recovers the electrolyte mixed in the extracted gas , which solves the problem of electrolyte corrosion and electrolyte waste of the whole equipment in the past. see figure 1 , shows the structural composition of the present invention.

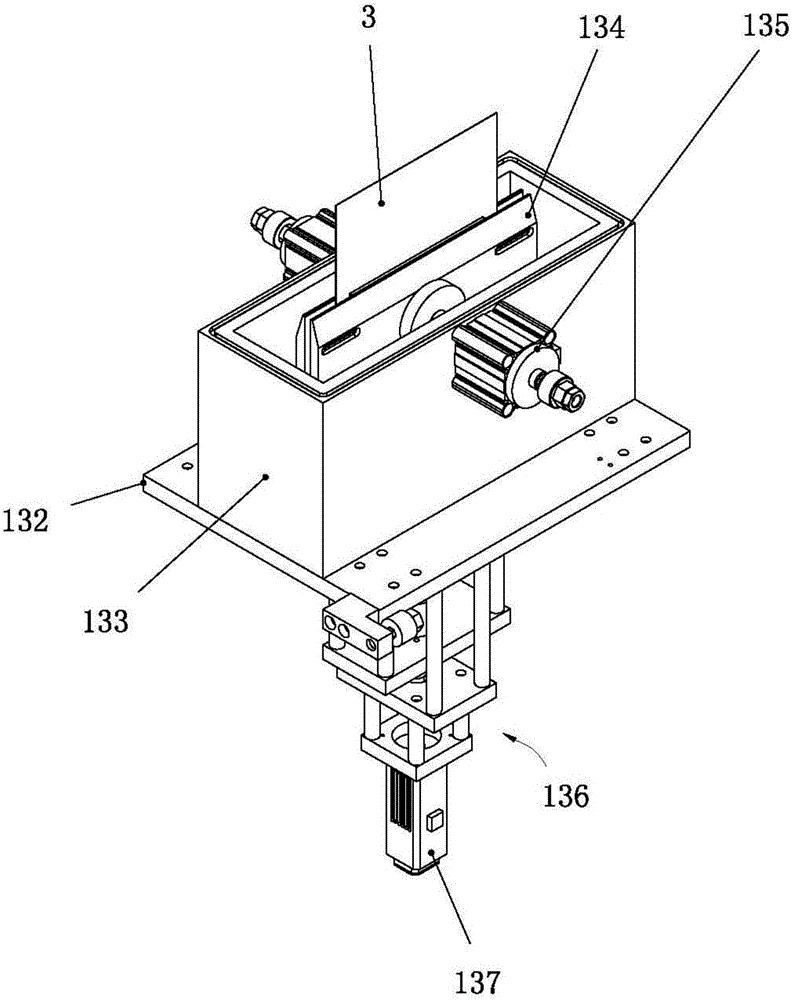

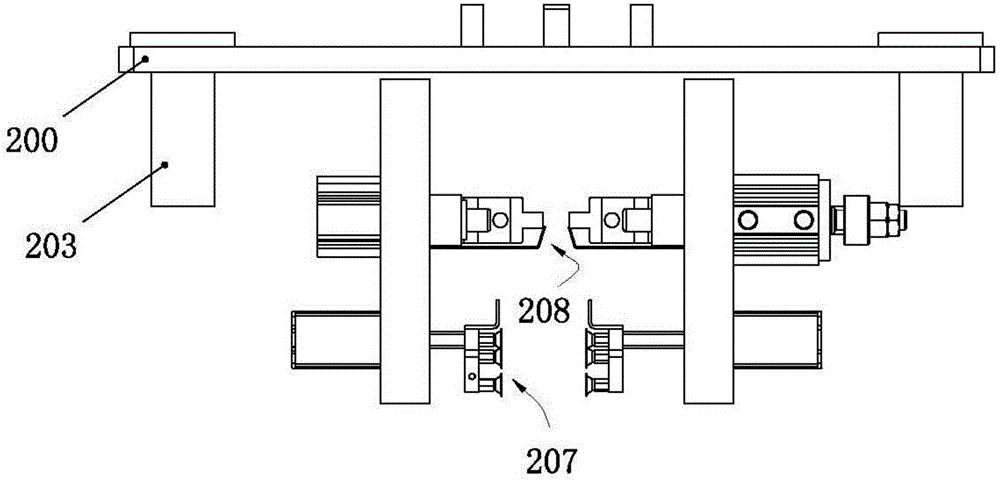

[0024] see Figure 1 to Figure 4 , a vertical packaging machine for pouch batteries provided in this embodiment, including a loading and unloading mechanism for vertically clamping and transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com