Ride-on rice transplanter or ride-on direct seeder

A technology of live broadcast machine and rice transplanter, which is applied in the direction of steering mechanism, vehicle parts, steering tie rod, etc., which can solve the problems of large impact load, increase the weight of gearbox, etc., and achieve improved support strength, reduced uneven wear, and reduced possibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

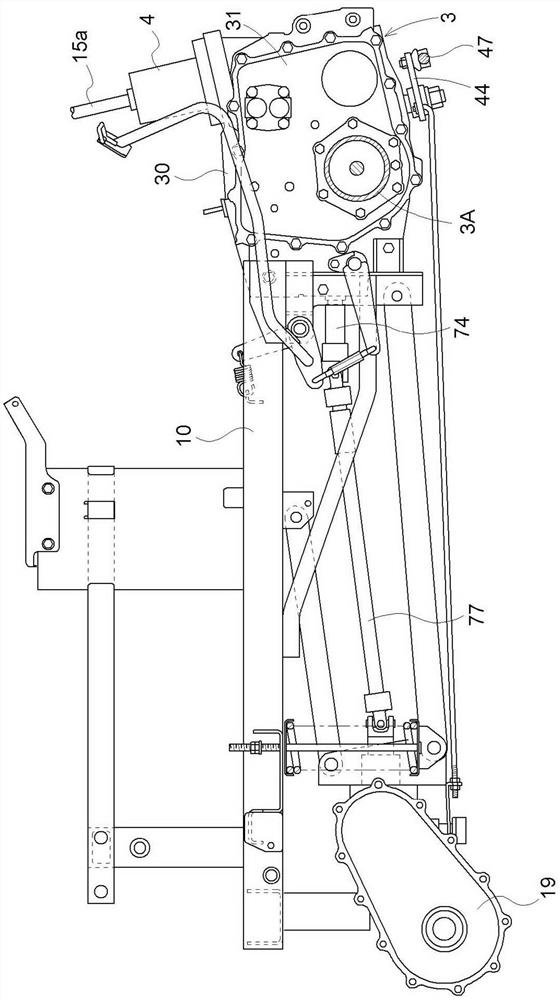

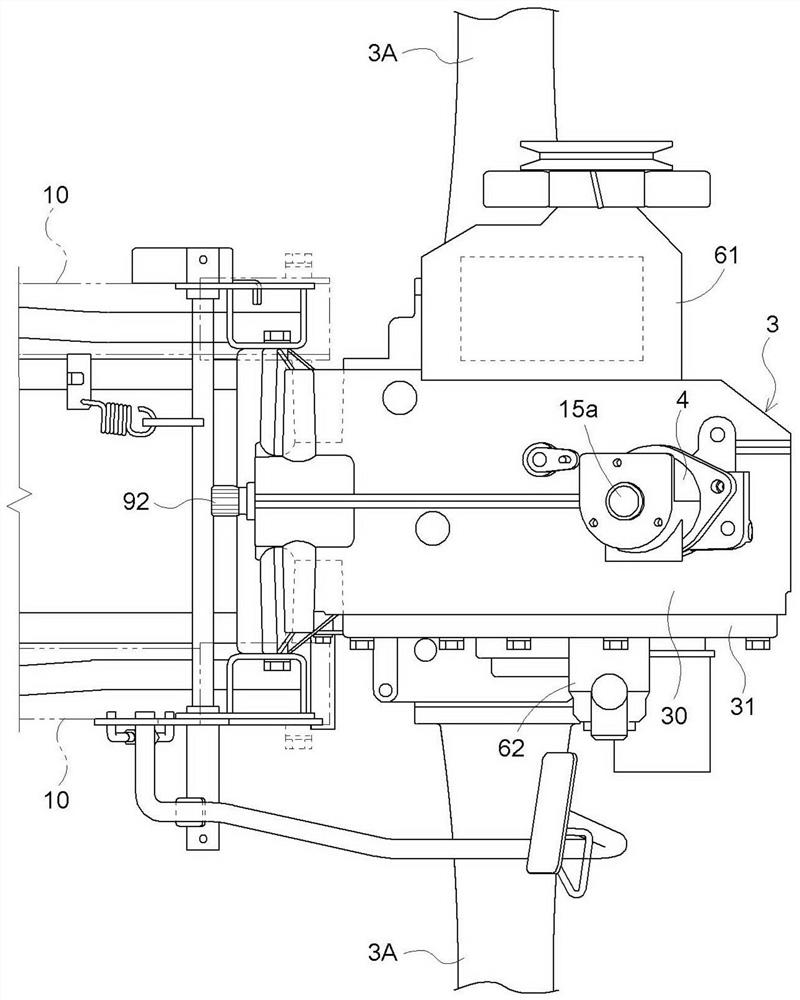

[0152] An example of an embodiment of the present invention will be described below with reference to the accompanying drawings.

[0153] [the whole frame]

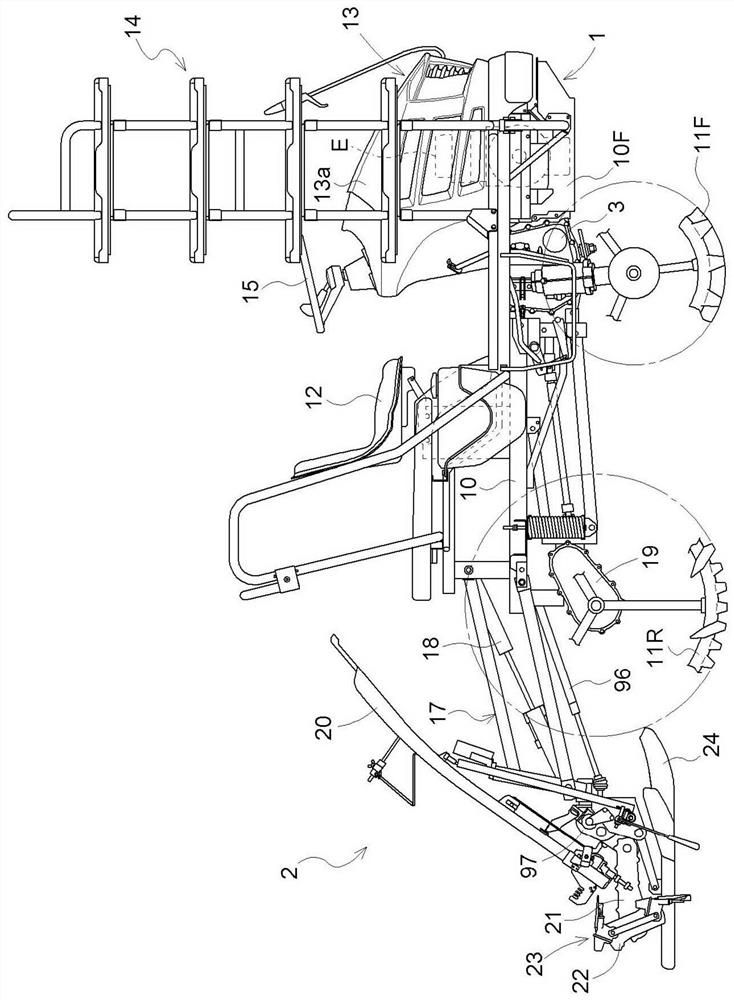

[0154] figure 1 The right side of the riding-type rice transplanter which is an example of a work vehicle is shown.

[0155] This ride-on rice transplanter has a self-propelled traveling vehicle body 1, and the traveling vehicle body 1 has a pair of left and right steering and drivable front wheels 11F and a pair of left and right rear wheels that can be driven freely under the vehicle body frame 10. 11R, and receives power from the engine E mounted on the vehicle body frame 10 to drive the front wheels 11F and rear wheels 11R.

[0156]On the traveling vehicle body 1, there is a power unit 13 in which the engine E is built in the front part of the body, and a preliminary seedling loading stand 14 is provided on both left and right sides. On the rear side of the power unit 13 , at the center portion in the front-rear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com