Passive stagnation control for solar collectors

A technology for solar collectors and solar energy absorption, applied in solar collector controllers, solar collectors, components of solar collectors, etc., can solve unit failures, increase collector costs, and exceed heat deflection temperature And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

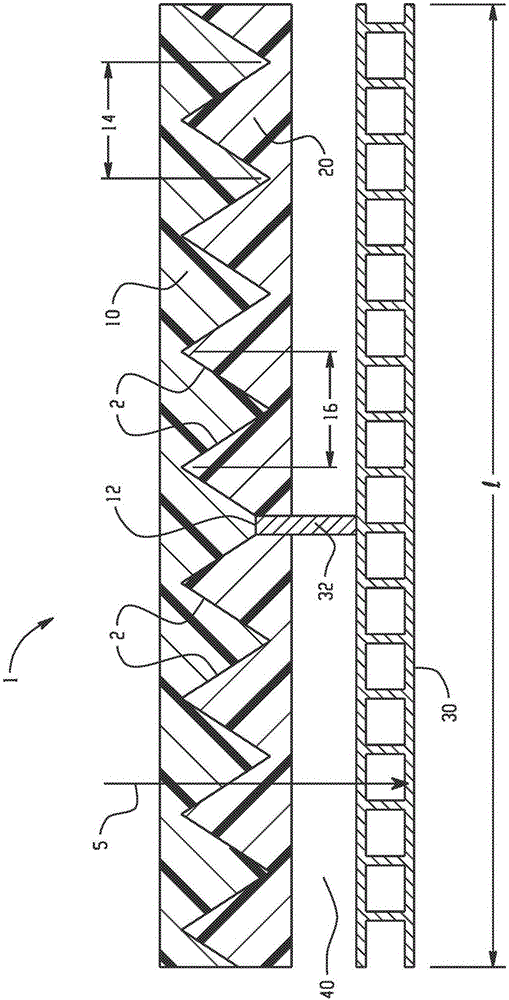

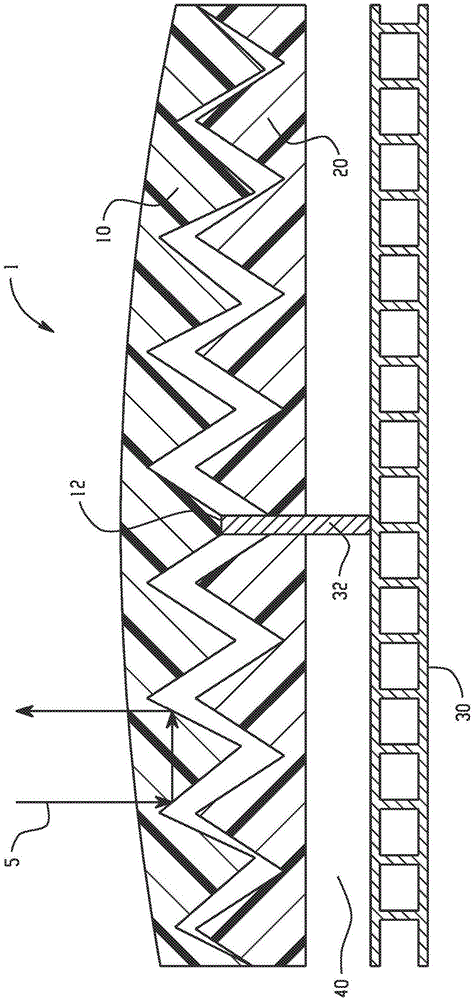

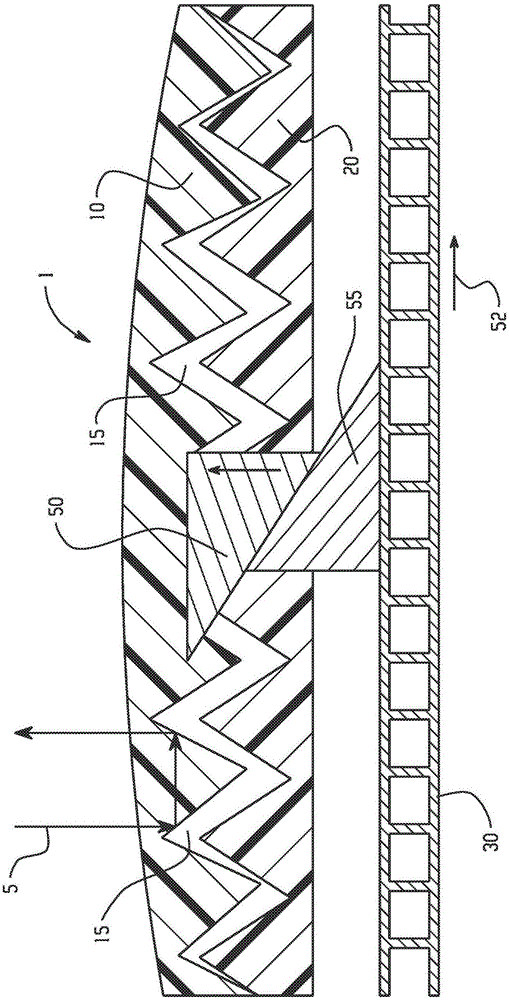

[0046] Embodiment 1: A solar collector comprising: a solar absorbing substrate; a first layer and a second layer above the solar absorbing substrate, each of the first and second layers comprising respective surfaces facing each other morphologies and defining an interface, the surface morphologies configured to transmit a selected portion of solar energy across the interface when aligned with each other, a transmittance greater than or equal to 80% as measured in accordance with ISO 9060:1990; and an actuator coupled to the solar energy absorbing substrate , in thermal communication with the solar absorbing substrate, the actuator is mechanically coupled to at least one of the first layer and the second layer; wherein the actuator is configured to receive thermal energy from the solar absorbing substrate and move the first layer and the second layer layer, to move the corresponding surface topography out of alignment, and have a light transmittance through the first layer of l...

Embodiment approach 2

[0047] Embodiment 2: The solar collector of Embodiment 1, wherein the respective surface topography comprises a complementary geometry at the interface between the first layer and the second layer.

Embodiment approach 3

[0048] Embodiment 3: The solar collector of any one of Embodiments 1 or 2, wherein each geometric configuration comprises a trapezoidal, zigzag, sinusoidal, laminar, triangular, abs(sin)-shaped, cycloidal shape, and At least one of the pyramidal geometric configurations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com