grinder

A technology of grinding machine and grinding cup, which is applied in the field of grinding machines, can solve the problems of material clogging above the grinding gap, grinding motor stalling, and grinding is not fine enough, so as to avoid material clogging and ensure the effect of grinding efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

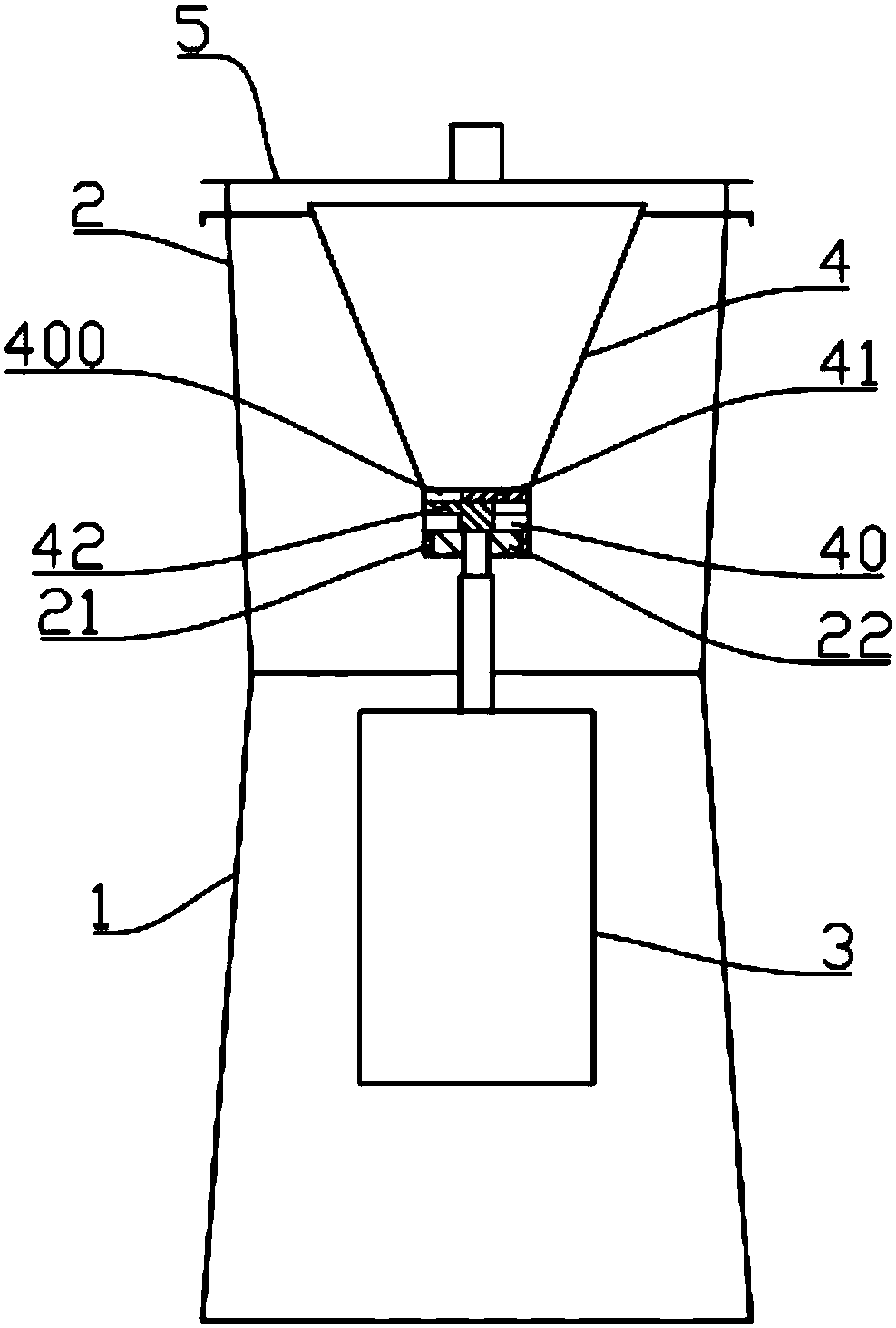

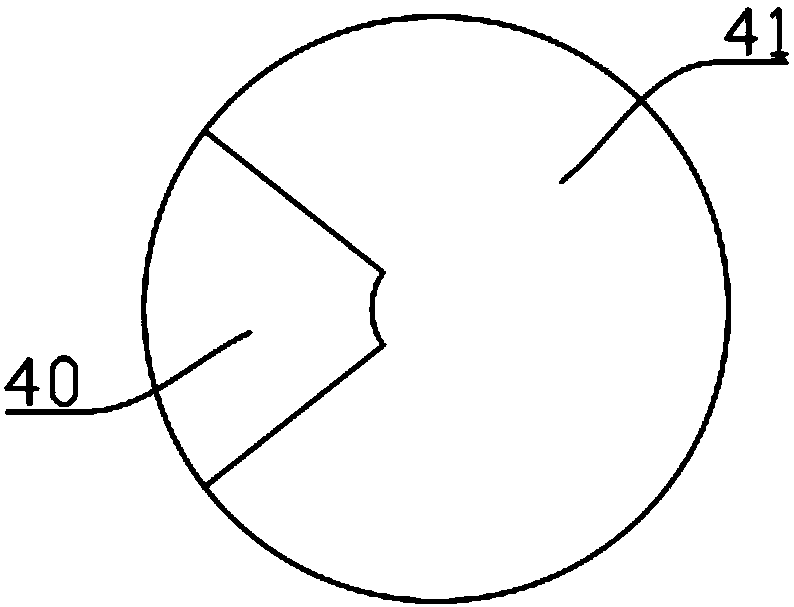

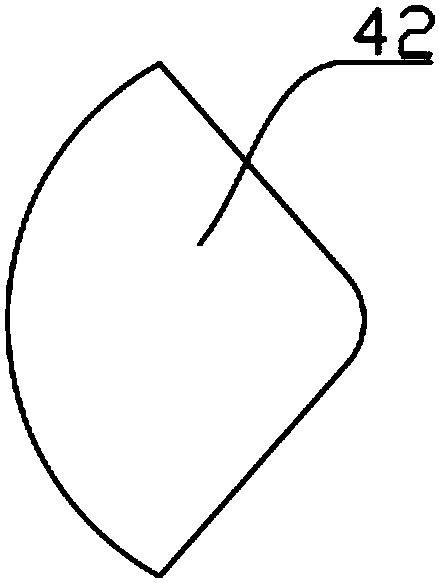

[0024] Such as figure 1 As shown, the grinding machine includes a base 1, a grinding cup 2 and a cup cover 5, the grinding cup 2 is installed on the top of the base 1, and the cup cover 5 covers the upper opening of the grinding cup 2, so The machine base 1 is provided with a grinding motor 3, the inside of the grinding cup 2 is provided with a feed hopper 4, and the bottom of the feed hopper 4 is provided with a grinding assembly, and the grinding assembly includes mutually matched Static grinding head 21 and dynamic grinding head 22, described static grinding head 21 is fixed on the described feed hopper 4, described moving grinding head 22 is arranged in the hollow cavity of static grinding head 21, and grinds The output shaft of the motor 3 is affixed; the top of the grinding assembly in the feed hopper 4 is provided with a fixed baffle 41, and part of the side of the fixed baffle 41 is connected with the side wall of the feed hopper 4, so The other side of the fixed baff...

Embodiment 2

[0029] In order to store water in the feed hopper 4 and realize grinding with water, on the basis of Embodiment 1, the movable baffle in this embodiment is sealed and attached to the bottom surface of the fixed baffle, so that it can be directly stored in the feed hopper 4. Mixture of water and material.

[0030] Such as Figure 4 As shown, a sealing rubber 43 can be provided on the movable baffle, and the sealing fit can be realized by the sealing rubber 43 being in close contact with the fixed baffle 41 . The sealing rubber 43 can be arranged along the edge of the movable baffle, and also can completely cover the movable baffle.

Embodiment 3

[0032] On the basis of embodiment 1 or embodiment 2, such as Figure 5 As shown, an upwardly protruding rib 411 is provided on the top surface of the fixed baffle 41 at the edge of the outlet 400 . The ribs can lift the material to prevent the material from clogging at the discharge port. In this embodiment, due to the influence of the ribs, the movable baffle is preferably attached to the bottom surface of the fixed baffle.

[0033] In addition, it can also be realized by setting a plurality of convex points on the top surface of the fixed baffle, or implementing ribs and convex points together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com