Grinding plate for ultra-fine grinding cyclic machining of steel balls and method for preparing steel balls by using grinding plate

A technology for cyclic processing and grinding plates, which is applied in the direction of ultra-finishing machines, metal processing equipment, grinding devices, etc., can solve the problems of batch production quantity decline, poor product consistency, bruises, etc., to ensure surface quality and dimensional accuracy, Ensure consistent quality and ease the effect of flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

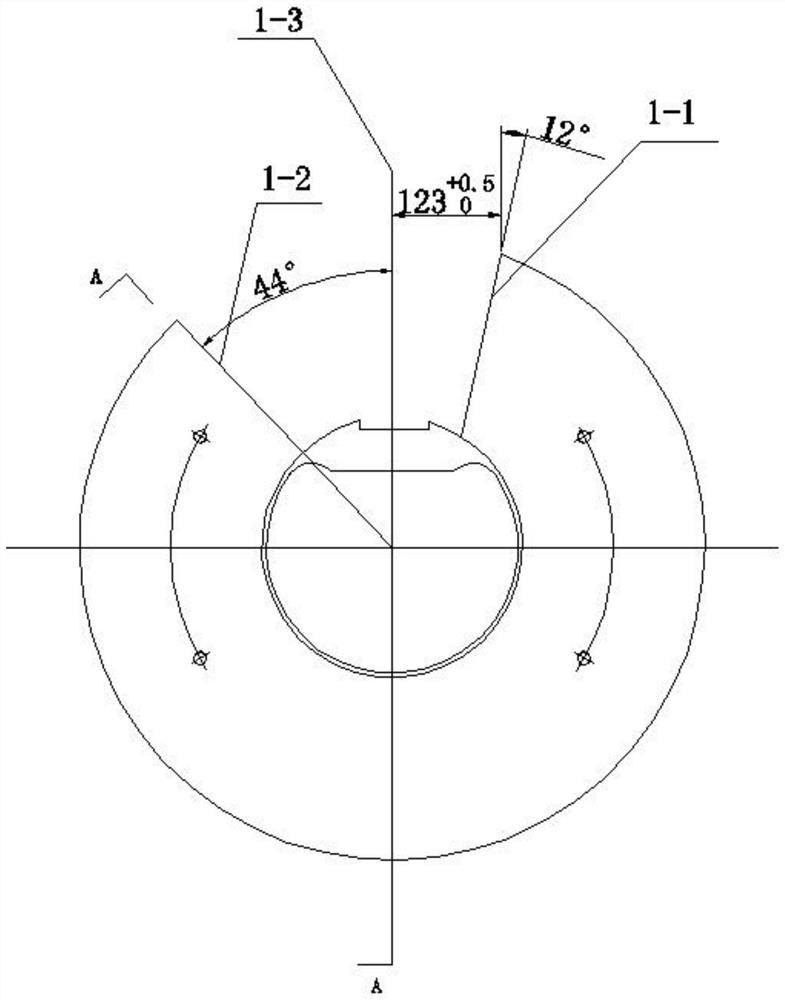

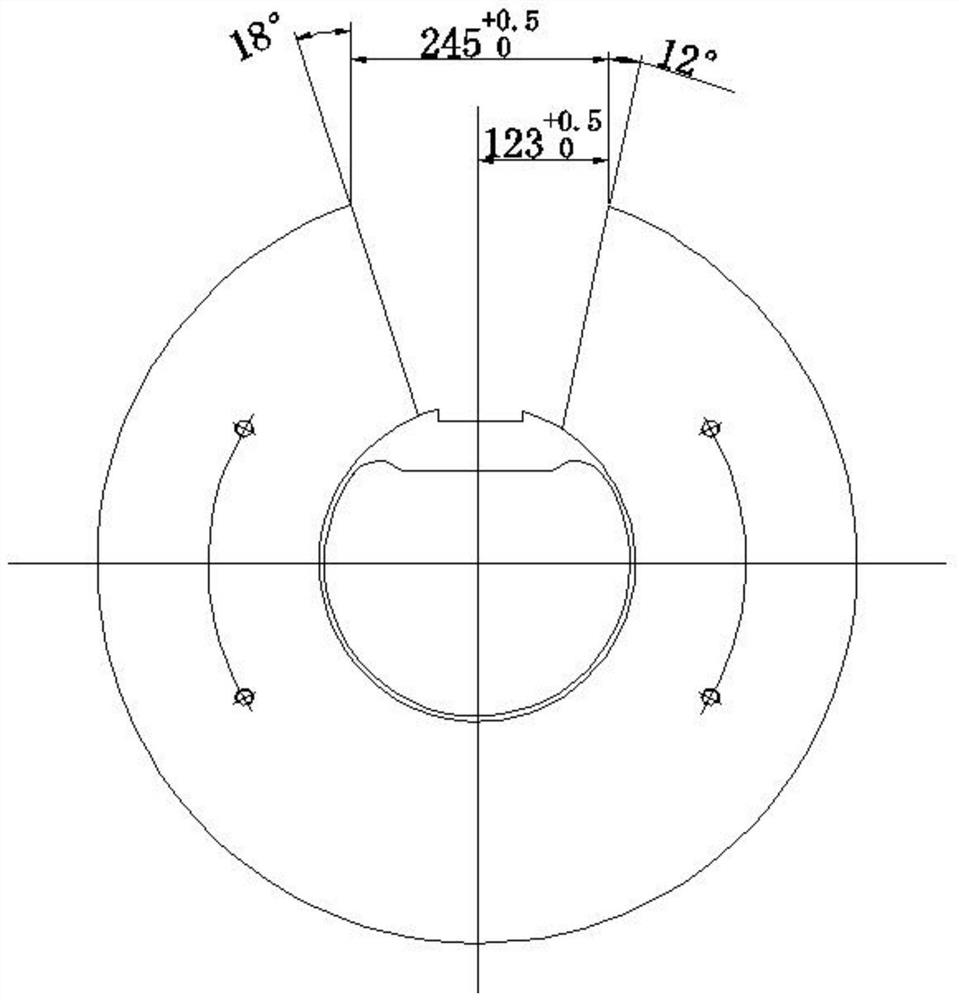

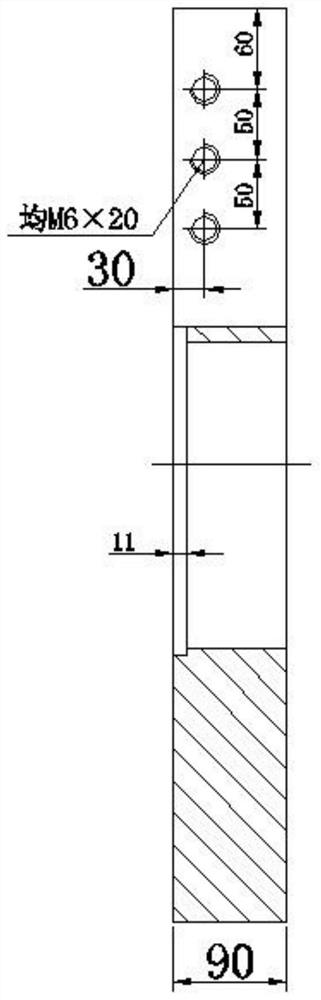

[0034] Specific embodiment one: the grinding plate of the steel ball ultra-finishing cycle processing in this embodiment, the central angle formed by the left boundary 1-2 of the opening of the grinding plate and the vertical central axis 1-3 is 40-44 degrees, and the opening of the grinding plate is The angle between the right boundary 1-1 and the vertical central axis 1-3 is 12 degrees, and the distance between the opening end of the right boundary 1-1 and the vertical central axis 1-3 is 123mm.

specific Embodiment approach 2

[0035] Embodiment 2: In this embodiment, the method of preparing steel balls by using the grinding plate of the steel ball ultra-finishing cycle processing described in Embodiment 1 is specifically carried out in the following steps:

[0036] 1. Cold stamping: Bring the polished steel material into the steel ball cold heading machine by the guide wheel, complete the cutting, send it to the center of the ball mold, and extrude to obtain the ball billet with the ring belt;

[0037] Two, annealing: carry out stress-relief annealing treatment in the heating furnace with the spherical billet obtained in step one;

[0038] 3. Light ball: put the ball billet processed in step 2 into the light ball machine for grinding to obtain a preliminary spherical steel ball;

[0039] Four, soft grinding one: adopt steel ball grinder to carry out spherical trimming to the steel ball obtained in step 3;

[0040] 5. Hot pickling: put the steel ball processed in step 4 into the acid solution for ac...

specific Embodiment approach 3

[0054] Embodiment 3: This embodiment is different from Embodiment 2 in that: the steel material in step 1 is 8Cr4Mo4V steel. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com