Diversion mechanism

A technology of deflector mechanism and deflector plate, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., and can solve the problems of excessive water flow, splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

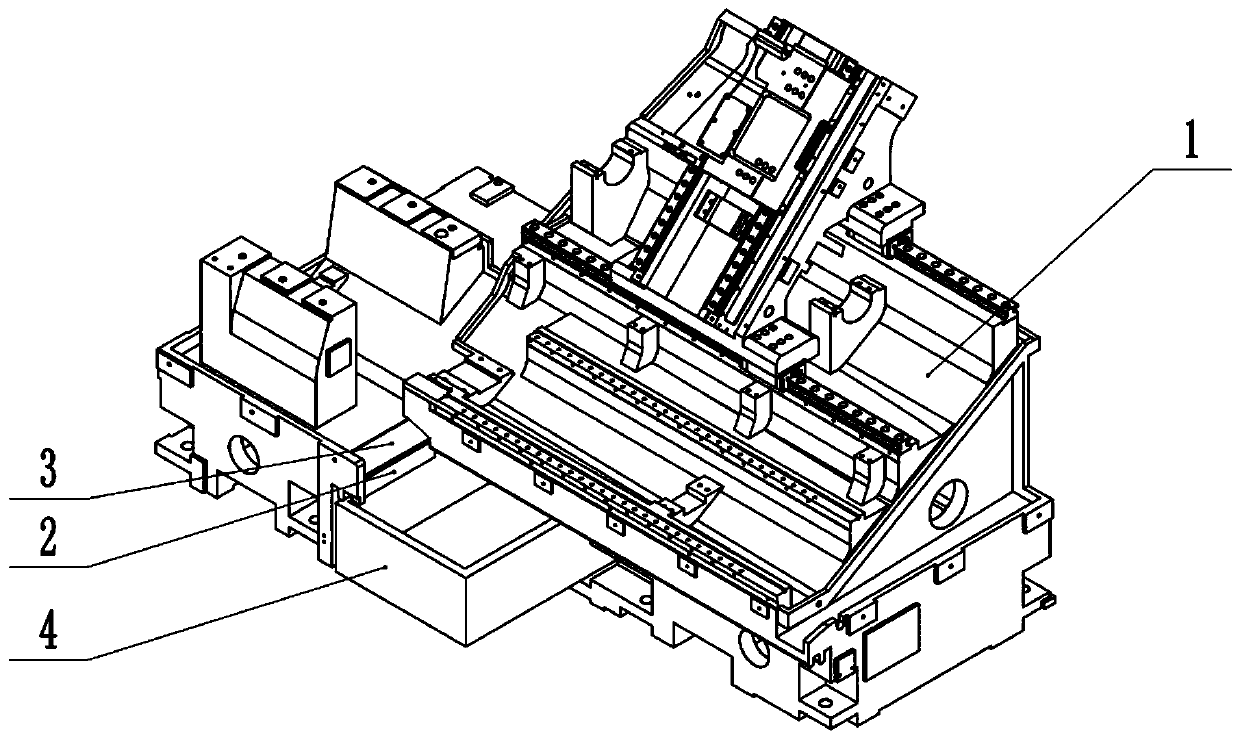

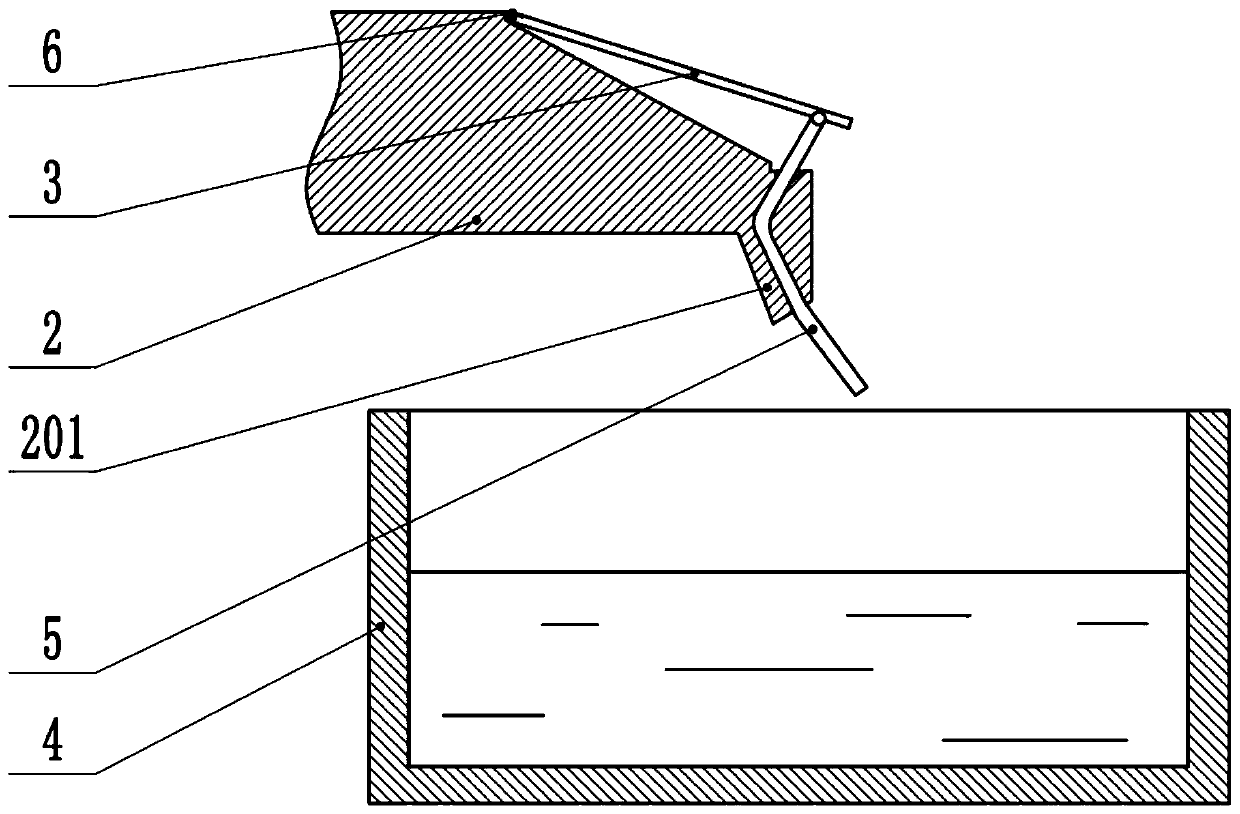

[0028] as attached figure 1 with attached figure 2 As shown, the guide mechanism includes a lathe 1 and a water tank 4. The diversion plate 2 is fixedly connected to the lathe 1 . The water tank 4 is horizontally slidably connected to the bottom of the lathe 1 . The diversion plate 2 is obliquely arranged on the top of the water tank 4, the inclination angle of the diversion plate 2 top surface is 120°, and the end of the diversion plate 2 away from the water tank 4 is the lowest end. The top surface of the diversion plate 2 is hinged with a diversion plate 3, the length of the diversion plate 3 along the inclined direction of the diversion plate 2 is greater than the length of the corresponding diversion plate 2, and a compression spring is fixedly connected between the top surface of the diversion plate 2 and the bottom surface of the diversion plate 3 . A rubber plate 5 is hinged at one end of the bottom surface of the deflector 3 away from the hinge of the deflector 3...

Embodiment 2

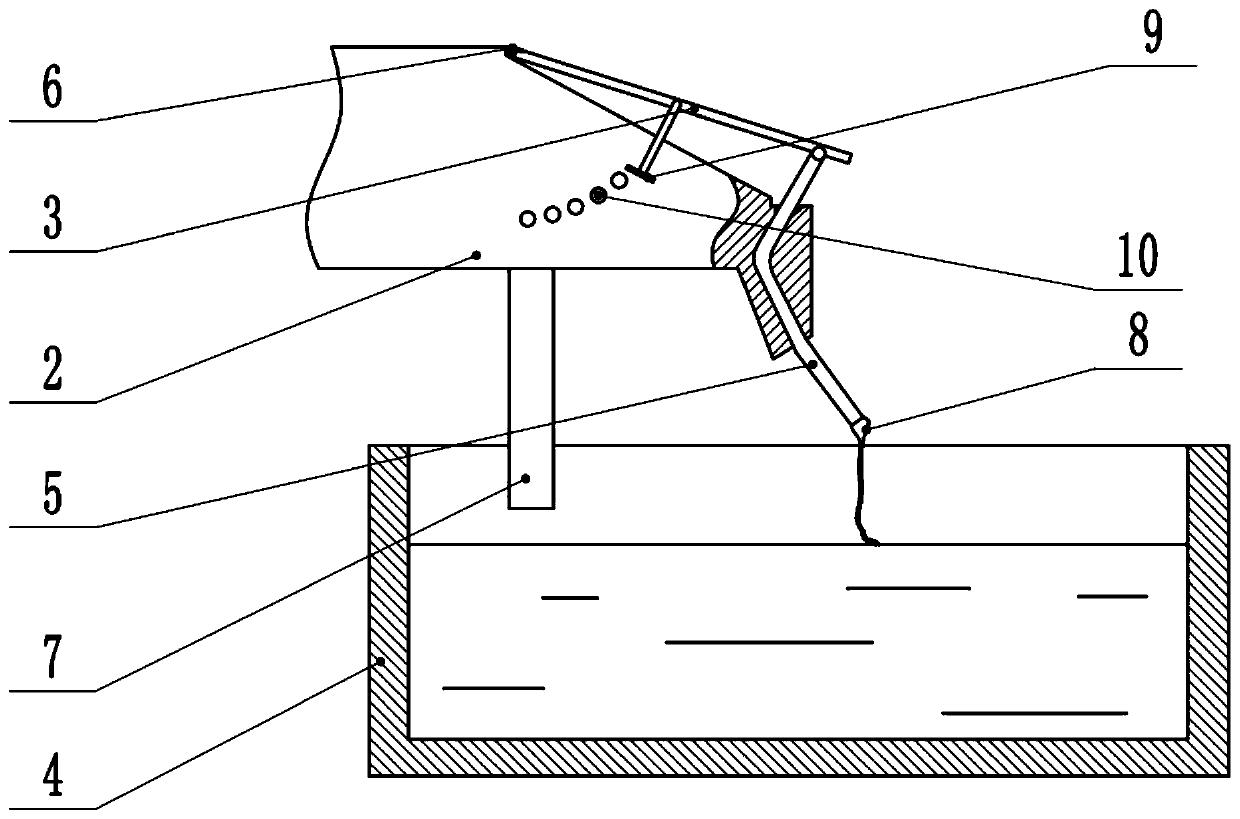

[0031] as attached image 3 As shown, the difference from Embodiment 1 is that the bottom surface of the drain plate 2 is also provided with a splash guard 7, the splash guard 7 and the drain plate 2 are integrally formed, and the bottom end of the splash guard 7 extends vertically downward , and the height of the bottom end of the splash guard 7 is less than the height of the top of the side wall of the water tank 4 . And the end of the rubber plate 5 away from the deflector 3 includes a layer of gauze 8, the height of the gauze 8 on the top surface of the deflector 3 is 3mm higher than the top surface of the deflector 3, and the end of the gauze 8 away from the deflector 3 extends out A piece of gauze 8, and extends to the liquid surface of water tank 4. The side wall of deflector 3 is threadedly connected to the strut, the axial direction of the strut is perpendicular to the bottom surface of deflector 3, the end of the strut away from deflector 3 extends to the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com