Resin sand mold

A resin sand and mold technology, used in the field of resin sand molds, can solve the problems of not being able to be tightly packed with the model, sticking, and affecting the quality of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

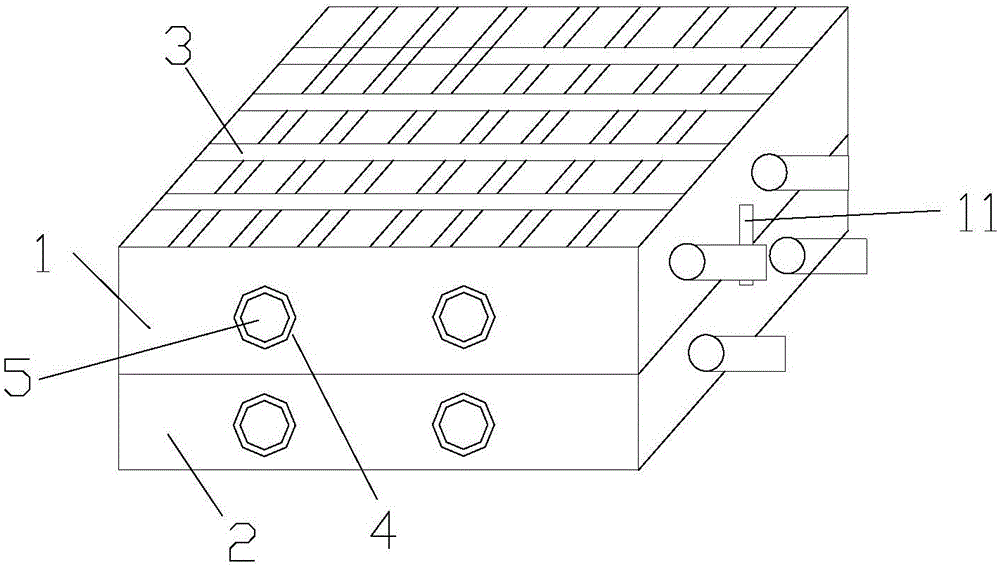

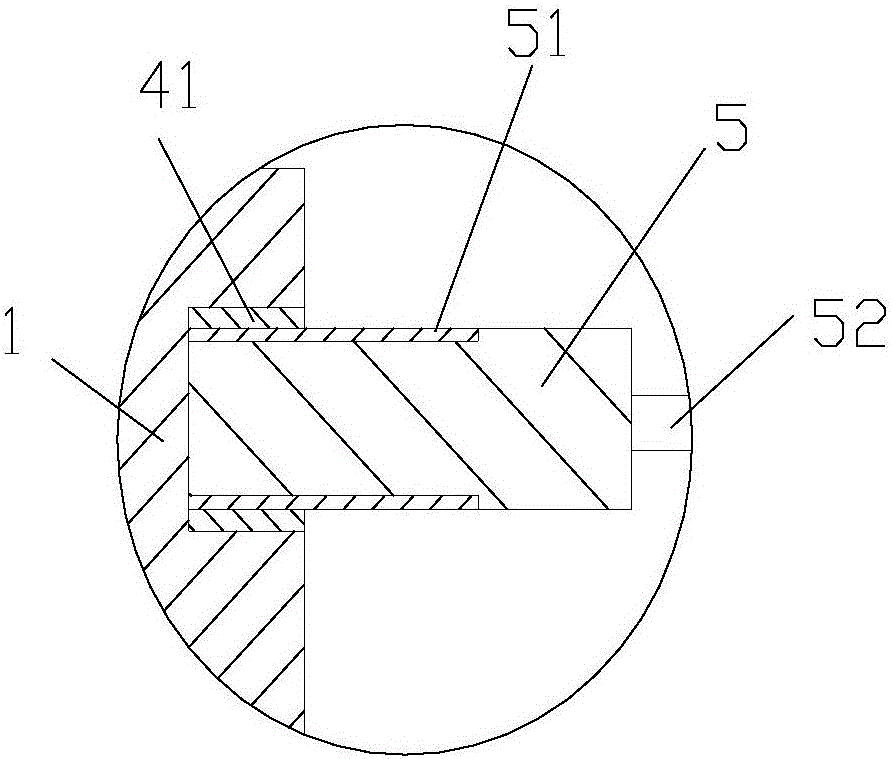

[0016] Such as figure 1 , figure 2 As shown, a resin sand mold is composed of an upper frame 1 and a lower frame 2, the upper frame 1 and the lower frame 2 are connected by a loose leaf, the two sides of the upper frame 1 and the lower frame 2 are hollowed out, and the top surface of the upper frame 1 and the lower frame The bottom surface of the frame 2 is respectively provided with a number of tiled iron bars 3, the iron bars 3 are intersected horizontally and vertically, the width of the iron bars is 0.5-1 cm, and the sides of the upper frame 1 and the lower frame 2 are provided with Several circular sockets 4 are provided with through cylinders 5, and the cylinders 5 and the sockets 4 are connected in a movable locking manner.

[0017] In order to conveniently lock the upper frame and the lower frame, a lock 11 for locking the upper frame 1 and the lower frame 2 is provided between the upper frame 1 and the lower frame 2 .

[0018] In order to ensure enough columns on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com