Monocular self-adaption cross laser visual corrugated plate welding line tracking sensor

An adaptive crossover and self-adaptive technology, applied in the field of weld seam tracking, can solve the problems of low production efficiency and achieve the effect of improving efficiency, improving precision and improving automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better express the technical solutions and beneficial effects of the entire invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation cases. Embodiments of the present invention are not limited thereto.

[0018] Step 1: Identification of the welding starting point of the corrugated plate.

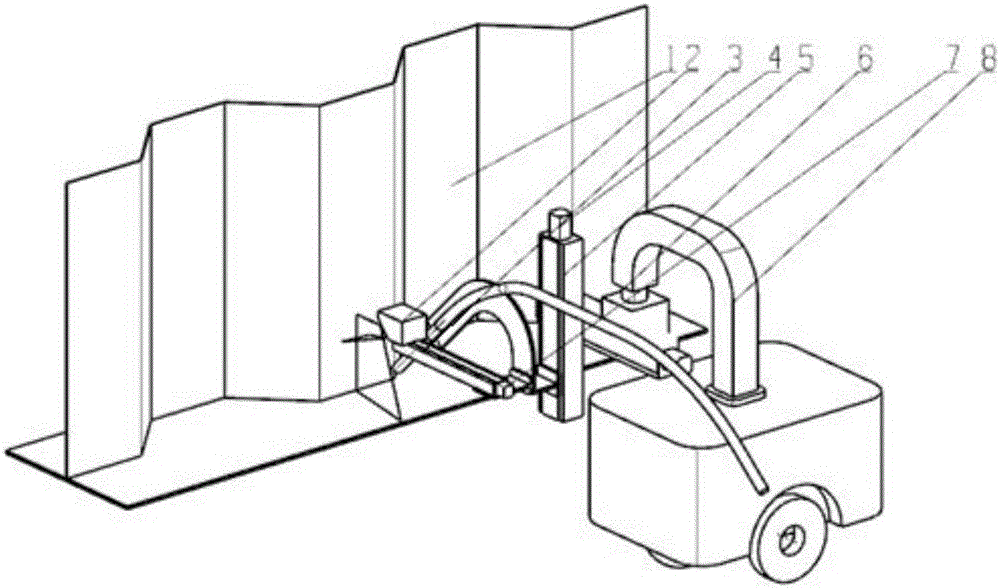

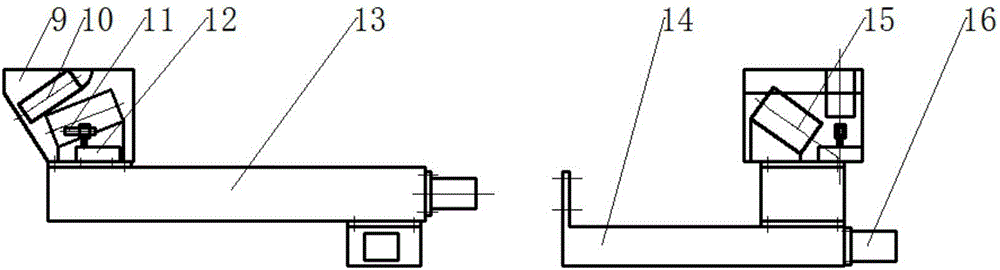

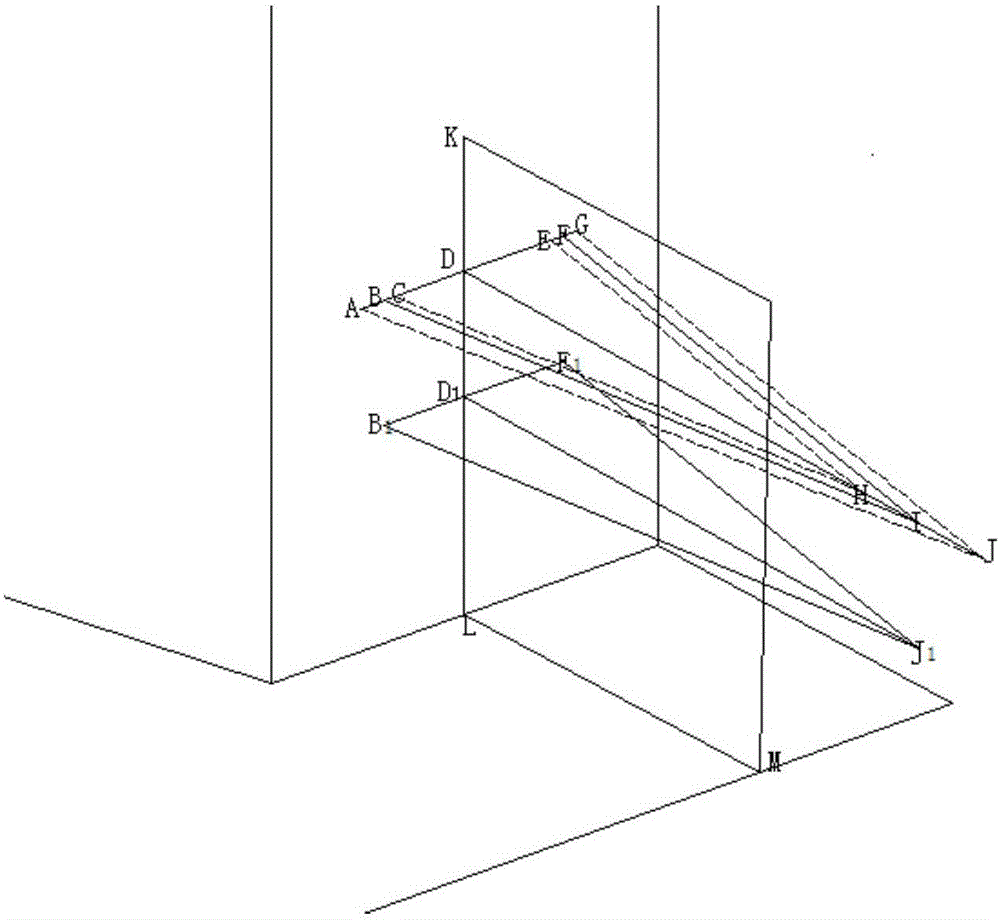

[0019] Set the required scanning laser length L before welding BF And the distance L from the intersection of the line laser and the weld to the intersection of the line laser and the scanning laser DL . The oscillating scanning laser emitted by the oscillating scanning laser device 11, 12 hits the corrugated plate, and the line laser emitter 10 emits the line laser and the camera 15 based on the linear array CCD takes pictures, and the camera 15 based on the linear array CCD captures the laser stripes, After image processing, the length L of the scanning laser is obtained BF1 , compare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com