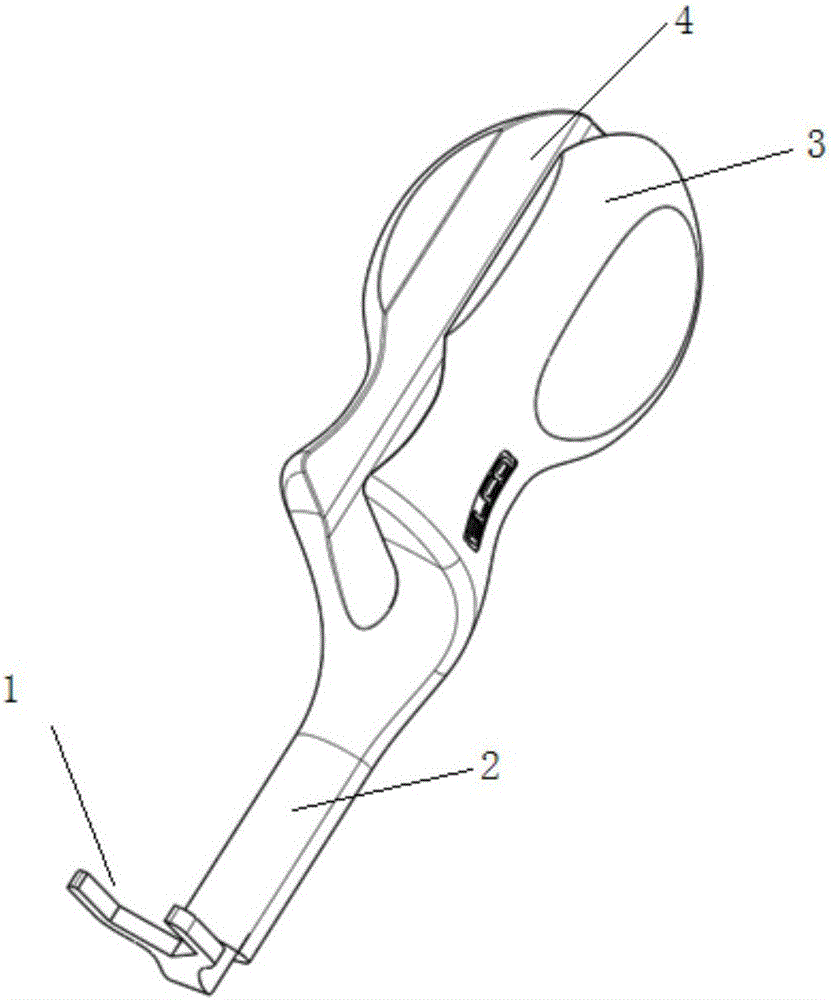

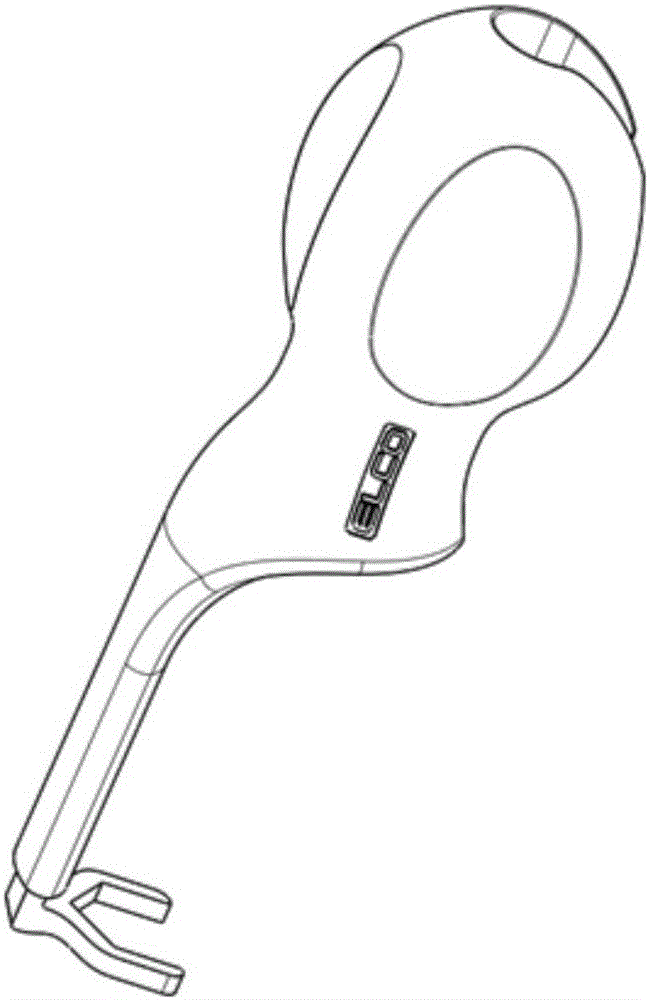

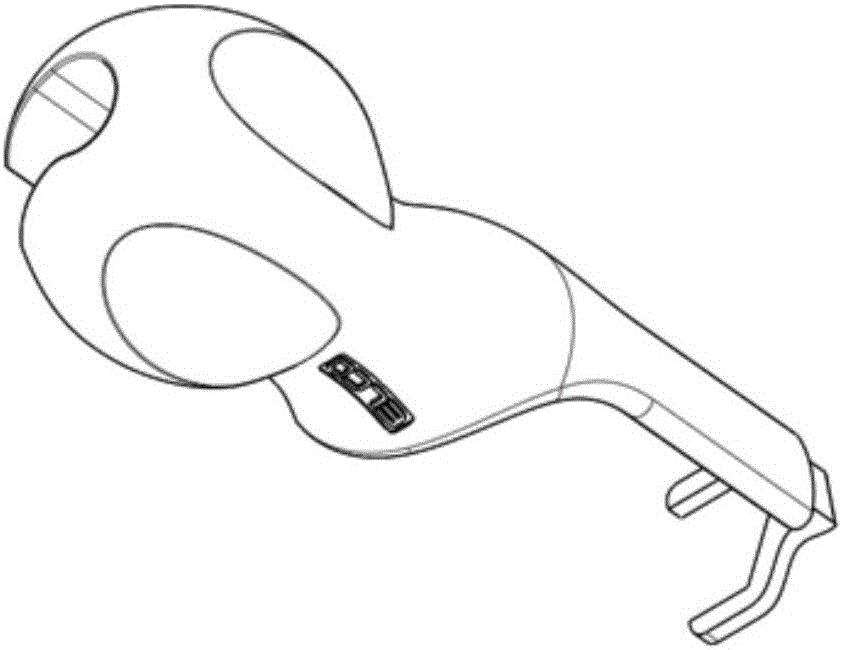

Pre-wired connector wrench

A connector and pre-injection technology, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve problems such as low efficiency and poor cable contact, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0022] It should be noted that the "connected" and the words used to express "connected" in this application, such as "connected", "connected", etc., can refer to the direct connection of a component with another component, It can also mean that a component is connected to another component through other components.

[0023] The present invention is mainly used for connector installation in a narrow space on site, and the cable is clamped into the handle to realize unrestricted continuous rotation. The invention utilizes the space inside the handle to place the cable, so that the rotation of the handle does not affect the cable at all, thereby realizing uninterrupted rotation, and greatly improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com