High-voltage and low-voltage power-on/off time sequence control method of pure electric vehicle

A pure electric vehicle, low-voltage controller technology, applied in electric vehicles, battery/fuel cell control devices, electrical devices, etc., can solve the problems of short service life, relay adhesion failure, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

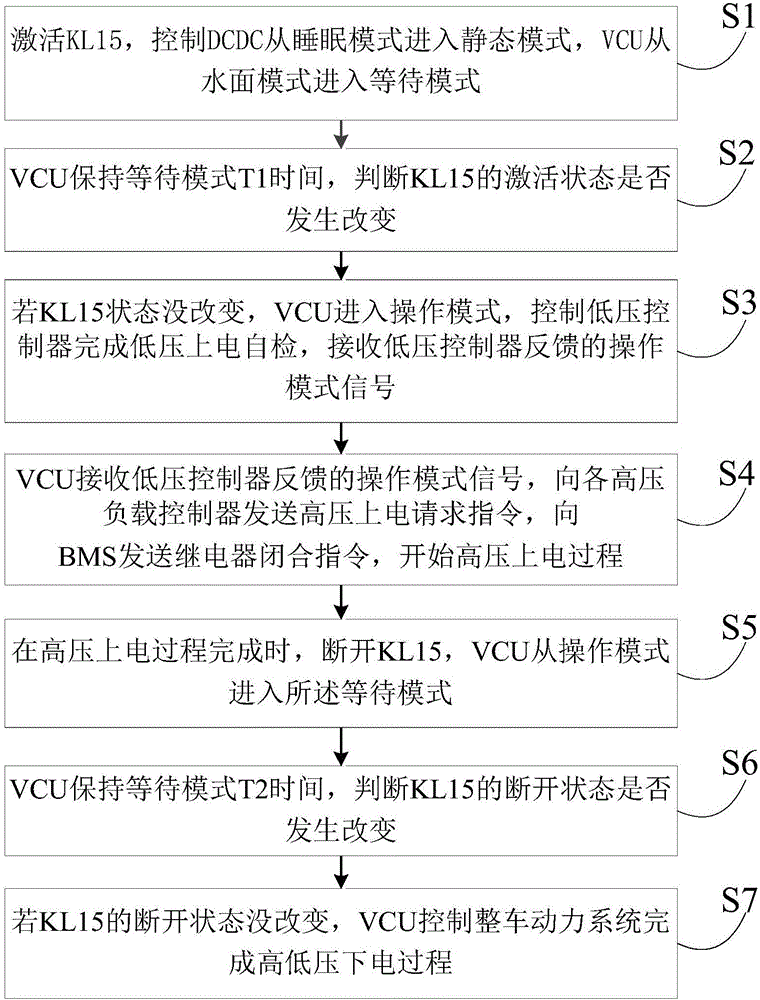

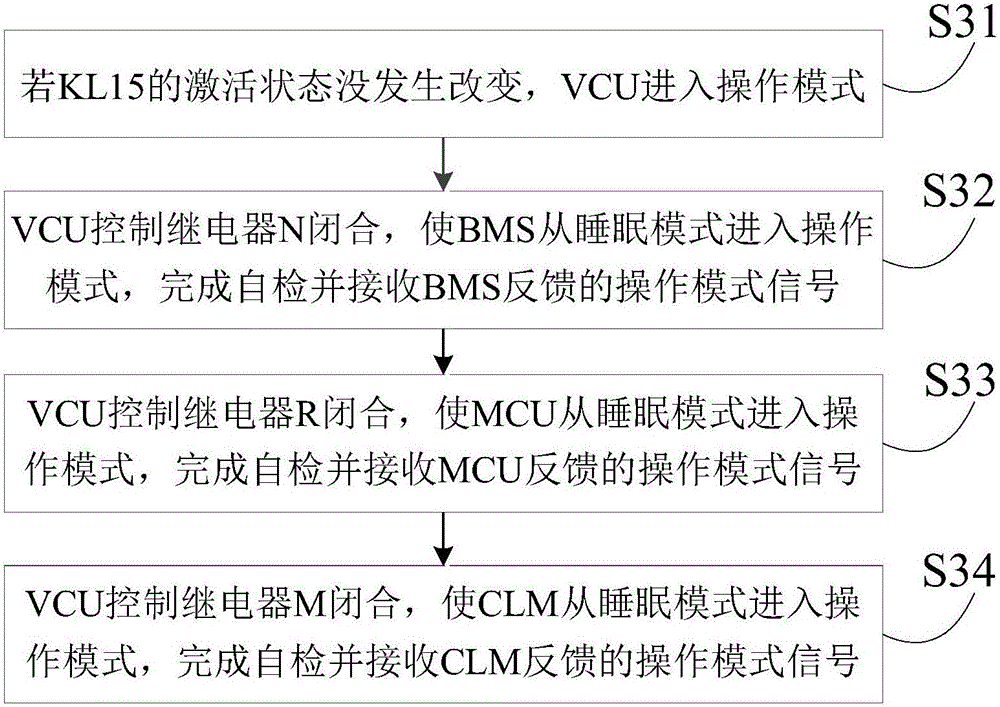

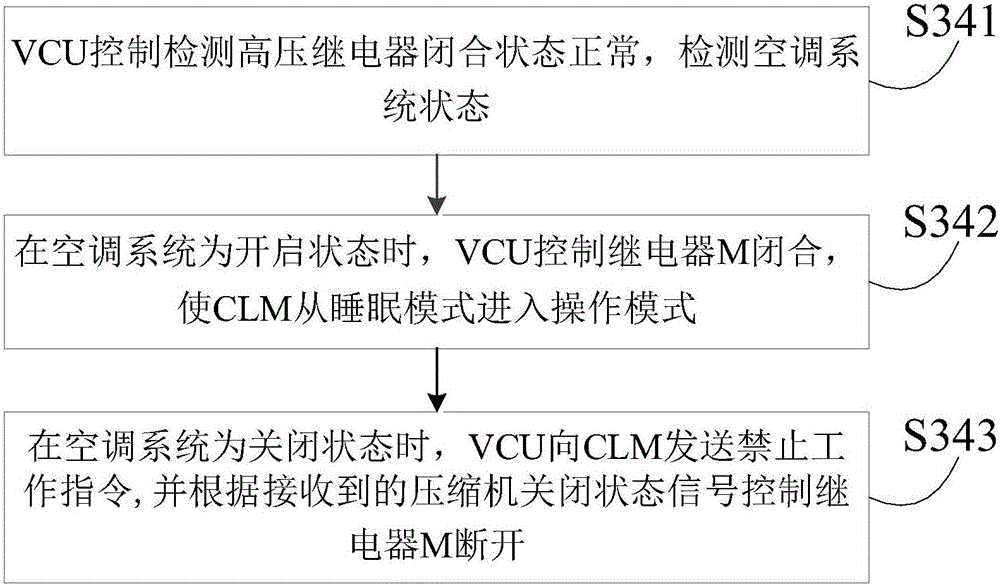

[0019] Combine below Figure 1 to Figure 4 , the present invention is described in further detail.

[0020] Such as figure 1 As shown, this embodiment provides a high and low voltage power-on and power-on sequence control method for pure electric vehicles, including the following steps S1 to S7:

[0021] S1. When the key switch KL15 is activated, the DC converter changes from the sleep mode to the static mode, and the vehicle controller VCU enters the waiting mode from the sleep mode;

[0022] S2. The VCU remains in the waiting mode for T1 time, and judges whether the activation state of the key switch KL15 changes, wherein T1 is a preset constant;

[0023] S3. If the activation state of the key switch KL15 does not change, the VCU enters the operation mode, controls the low-voltage controller to complete the low-voltage power-on self-test process and receives the operation mode signal fed back by the low-voltage controller;

[0024] S4. When the VCU receives the operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com