Box lowering mechanism

A technology for lowering and supporting boxes, applied to conveyors, conveyor objects, destacking of objects, etc., can solve problems such as inability to use a universal transmission mechanism, inability to accurately separate trays, and inability to accurately insert fork plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

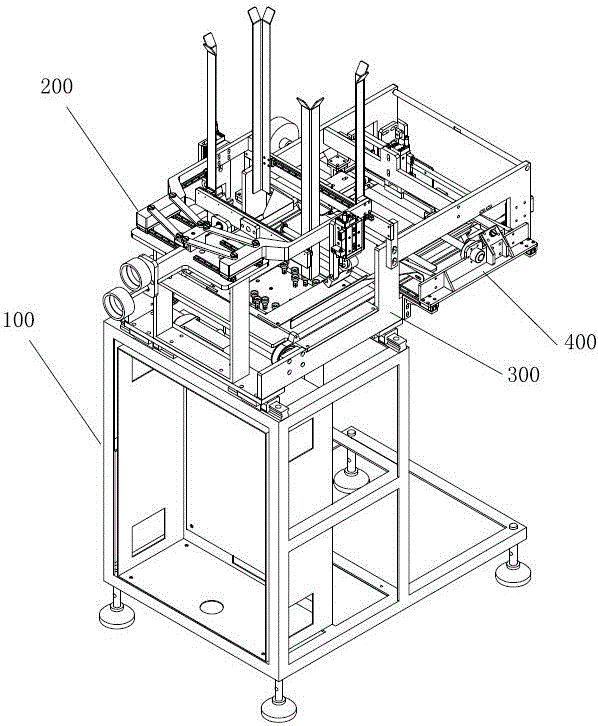

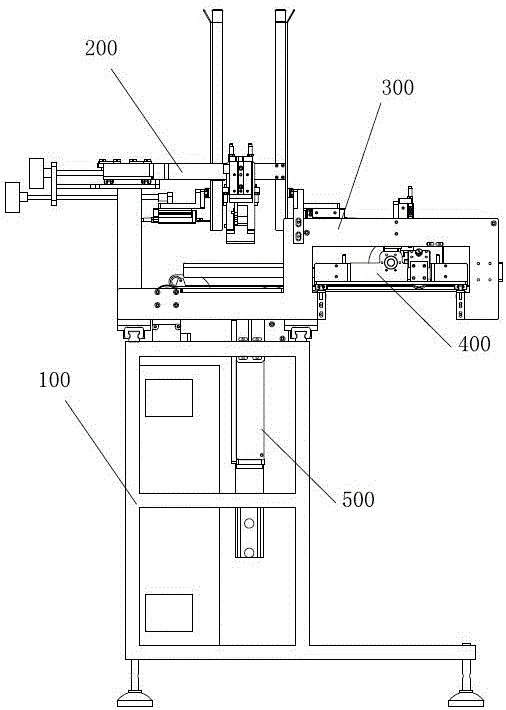

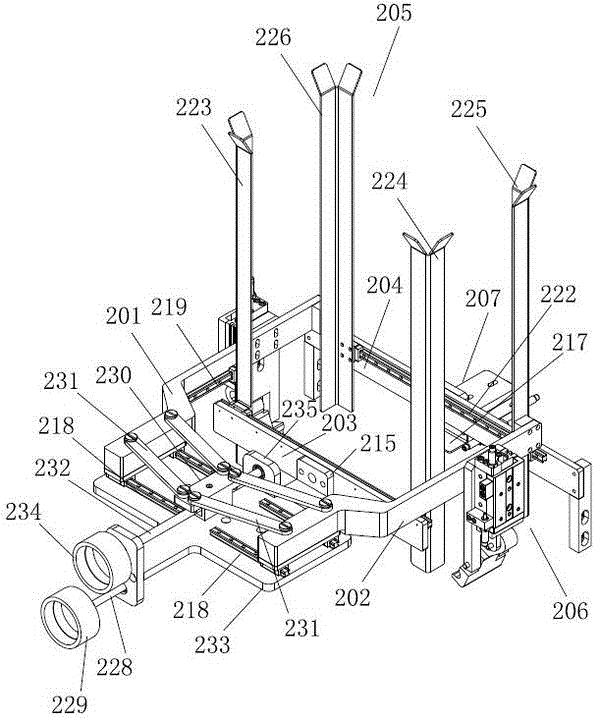

[0108]A lower box mechanism includes a support 100, a box loading frame, a tray conveying pusher 300 for pushing the tray horizontally, and a tray positioning pusher 400 for pushing the tray downward, and the bracket 100 is provided with In the box loading frame, one end of the tray delivery pushing part 300 is located below the box loading frame, the other end of the tray delivery pushing part 300 is located below the tray positioning pushing part 400, and the tray delivery pushing part 300 Located next to the box-loading frame, a lifting and absorbing component 500 for absorbing the tray is also arranged below the box-packing frame, and the lifting and absorbing component 500 is connected with the bracket 100 .

[0109] The tray is placed in the box loading frame, and the lowermost tray is absorbed by the lifting and absorbing part 500, and then falls onto the tray conveying pushing part 300, and then the tray conveying pushing part 300 translates and pushes the tray to the p...

Embodiment 2

[0122] A lower box mechanism includes a support 100, a box loading frame, a tray conveying pusher 300 for pushing the tray horizontally, and a tray positioning pusher 400 for pushing the tray downward, and the bracket 100 is provided with In the box loading frame, one end of the tray delivery pushing part 300 is located below the box loading frame, the other end of the tray delivery pushing part 300 is located below the tray positioning pushing part 400, and the tray delivery pushing part 300 Located next to the box-loading frame, a lifting and absorbing component 500 for absorbing the tray is also arranged below the box-packing frame, and the lifting and absorbing component 500 is connected with the bracket 100 .

[0123] The tray is placed in the box loading frame, and the lowermost tray is absorbed by the lifting and absorbing part 500, and then falls onto the tray conveying pushing part 300, and then the tray conveying pushing part 300 translates and pushes the tray to the ...

Embodiment 3

[0152] On the basis of the embodiment 1-2, the tray conveying pusher 300 includes a horizontal frame 301, the horizontal frame 301 is provided with a driving shaft 302, both ends of the main transmission shaft are connected with a timing belt 303, the The timing belt 303 is provided with a push rod 304 for horizontally pushing the tray, the bottom of the horizontal frame 301 is an open structure, the driving shaft 302 is connected with a first motor 305 to drive its rotation, the timing belt 303 The other end is provided with a driven shaft 306 , and both the driving shaft 302 and the driven shaft 306 are installed on the horizontal frame 301 . The bottom of the horizontal frame 301 is provided with an open structure. One is to make things easier for the tray when it falls on the tray conveying part. Subsequently, it can be pushed down from the tray conveying pushing part 300 to other stations. Theoretically, the driven shaft 302 can also be provided with the driven shaft 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com