Two-way throttle valve and pantograph air supply control system formed by same

A two-way throttling valve and pantograph technology, which is applied in the direction of valve housing structure, valve operation/release device, lift valve, etc., can solve the problems of large space occupation, unreasonable design, inconvenient maintenance, etc., and achieve simple structure, Avoid too fast action and avoid the effect of excessive transient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

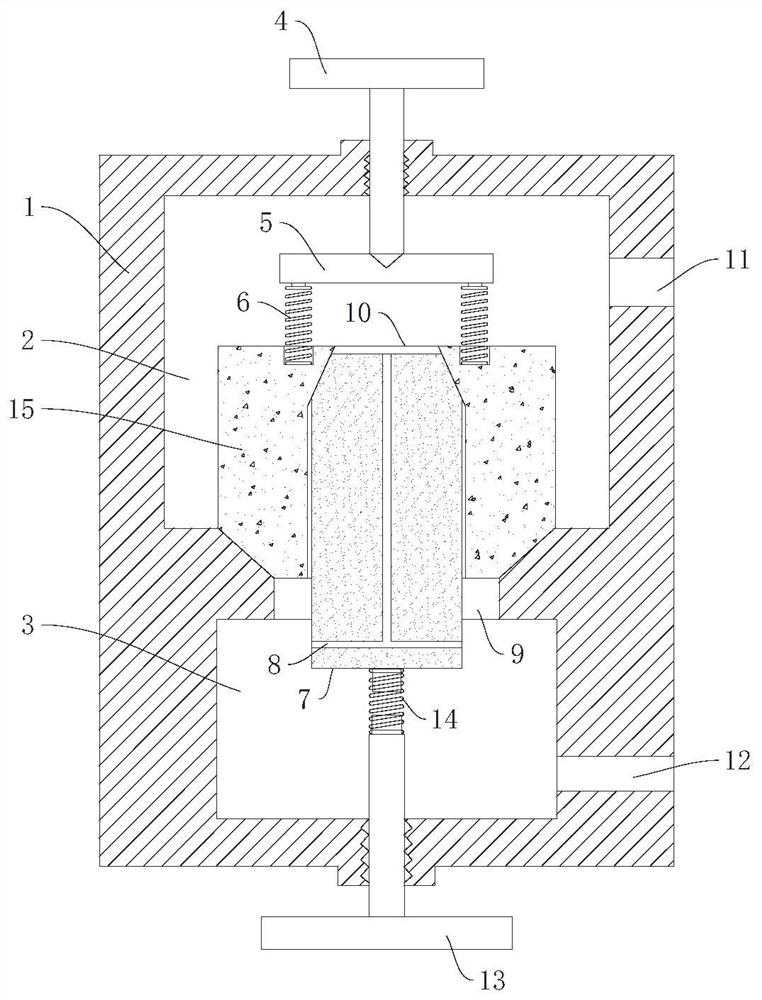

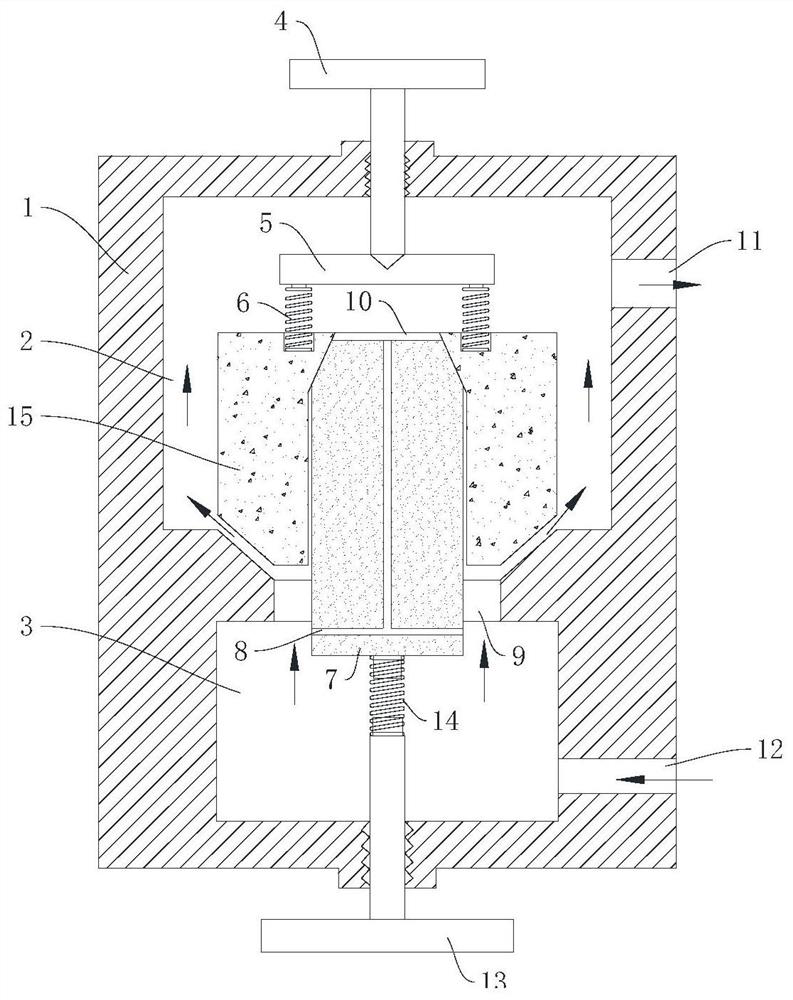

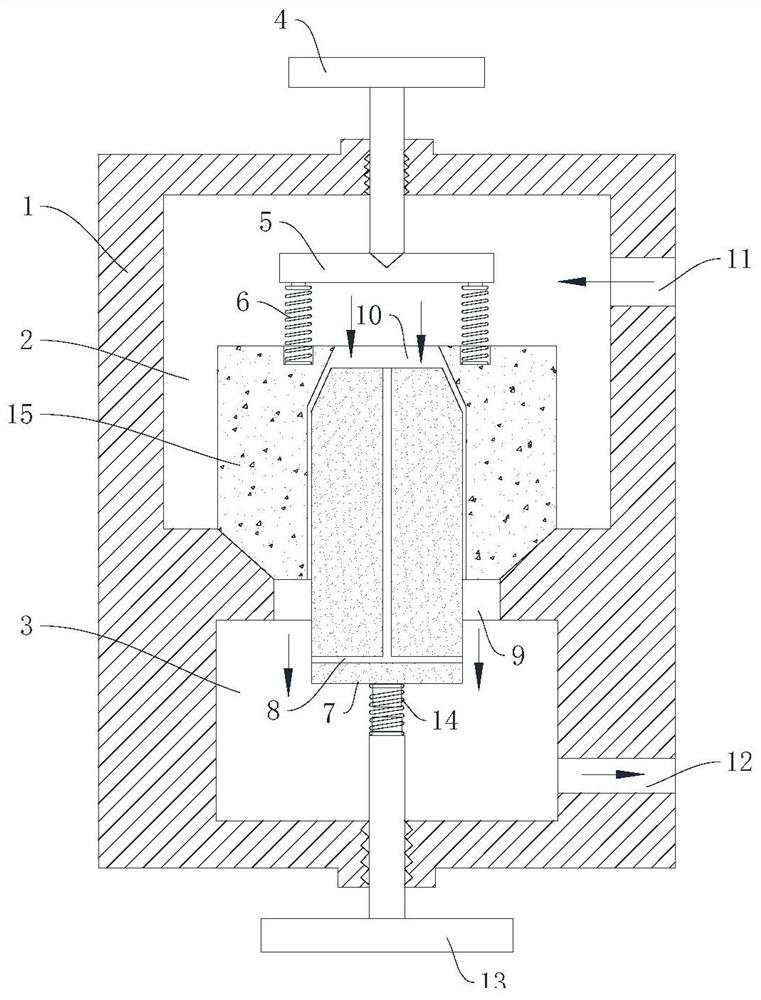

[0033] Such as figure 1 As shown, this embodiment mainly solves the structural optimization of the throttle valve. The existing throttle valve is generally a one-way throttling valve. And avoid excessive pressure transients of the fluid pressure medium.

[0034]The specific scheme adopted is: a two-way throttle valve, including a valve body 1 and a valve core, the valve body 1 is provided with a first chamber 2 communicating with the pressure medium and a second chamber 3 communicating with the actuator, A communication port 9 is provided between the first chamber 2 and the second chamber 3. The valve core includes an outer core 15 and an inner core 7 that are nested, and the outer core 15 is inside the first chamber 2. Sliding and used to open and close the communication port 9, the first chamber 2 is provided with a first elastic component for pressing against the outer core 15 and making the outer core 15 close the communication port 9; the outer core 15 is provided with a...

Embodiment 2

[0050] The above-mentioned embodiment discloses the technical solution of the two-way throttle valve, and this embodiment provides a technical solution for applying the two-way throttle valve to the pantograph air supply control system, specifically as follows:

[0051] Such as Figure 5 As shown, a pantograph air supply control system integrating a two-way throttle valve adopts the two-way throttle valve described in Embodiment 1, and the first chamber 2 of the two-way throttle valve communicates with the air duct of the pantograph , the second chamber 3 is sequentially communicated with the electromagnetic control valve 17, the pressure reducing valve 16 and the gas source.

[0052] The electromagnetic control valve 17 adopts a two-position three-way electromagnetic valve. Among them, one working position of the solenoid valve is connected to the gas source and the two-way throttle valve, and the gas medium from the gas source is sent to the second chamber 3 to help the pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com