A special vehicle for composite material detection of aircraft outer wing and horizontal tail

A special vehicle and outer wing technology, applied in the direction of the lifting device, etc., can solve the problems of not being able to move at will, difficult to detect and operate the lower wall, and no space for the ladder to be placed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

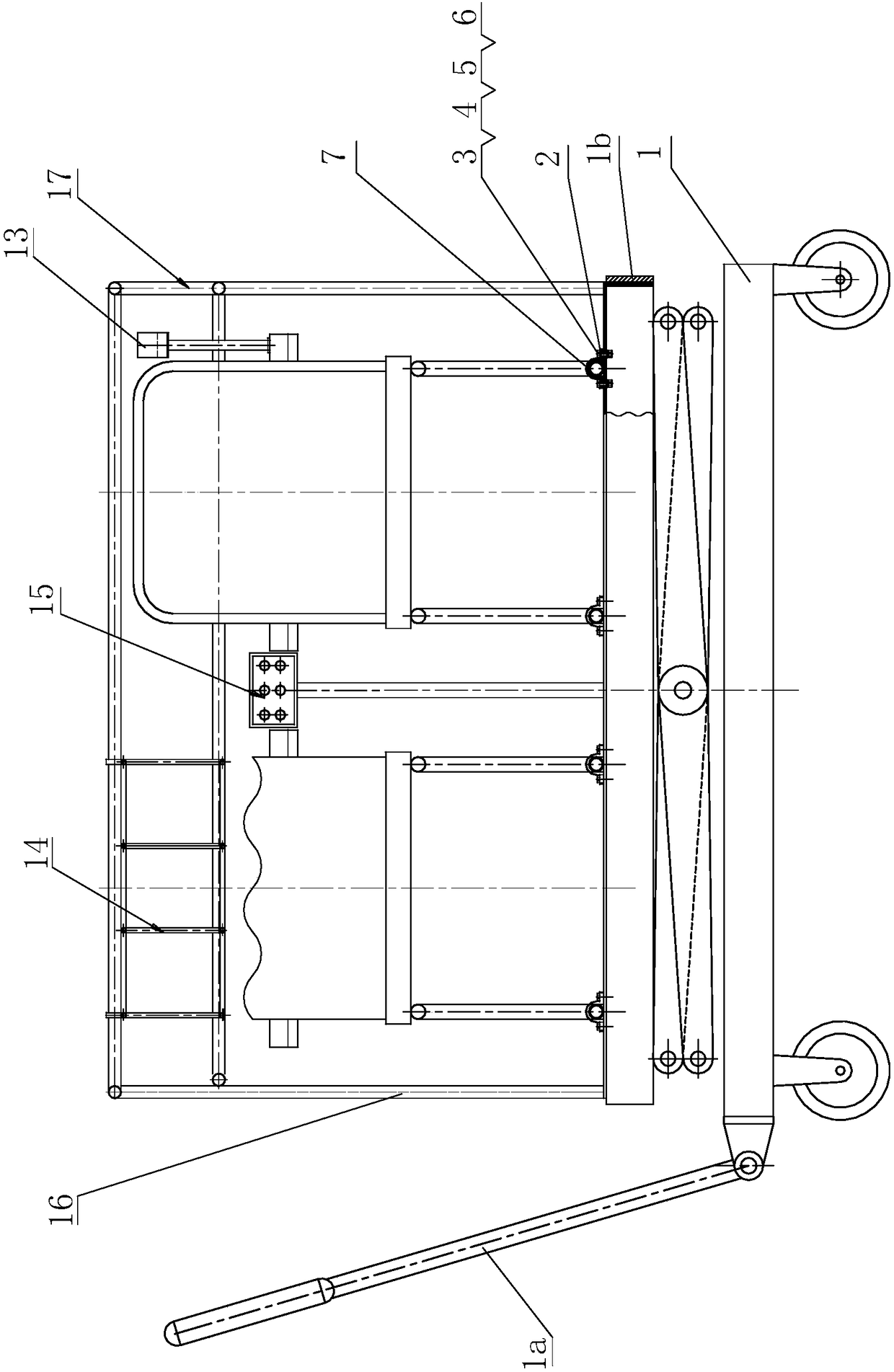

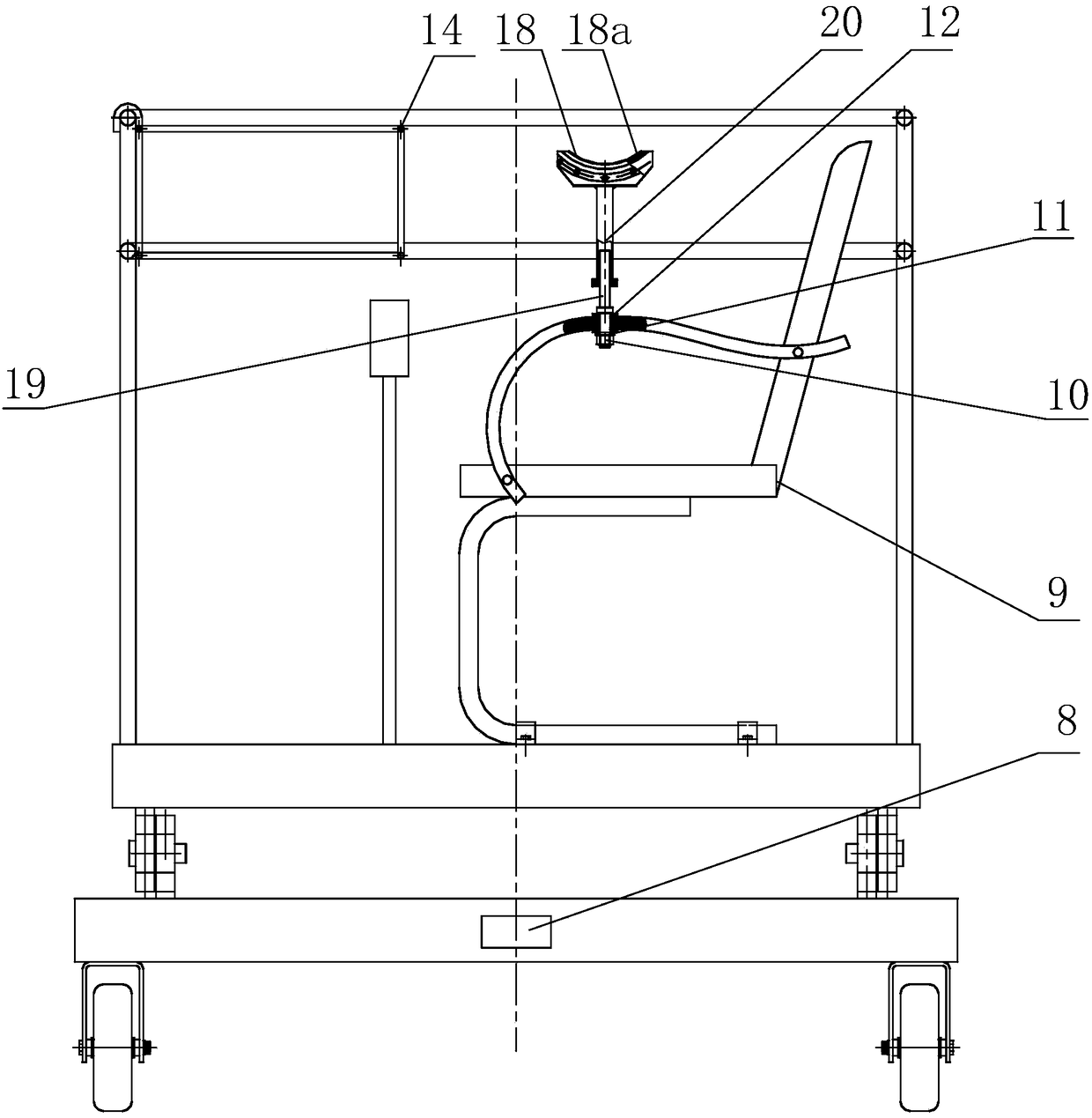

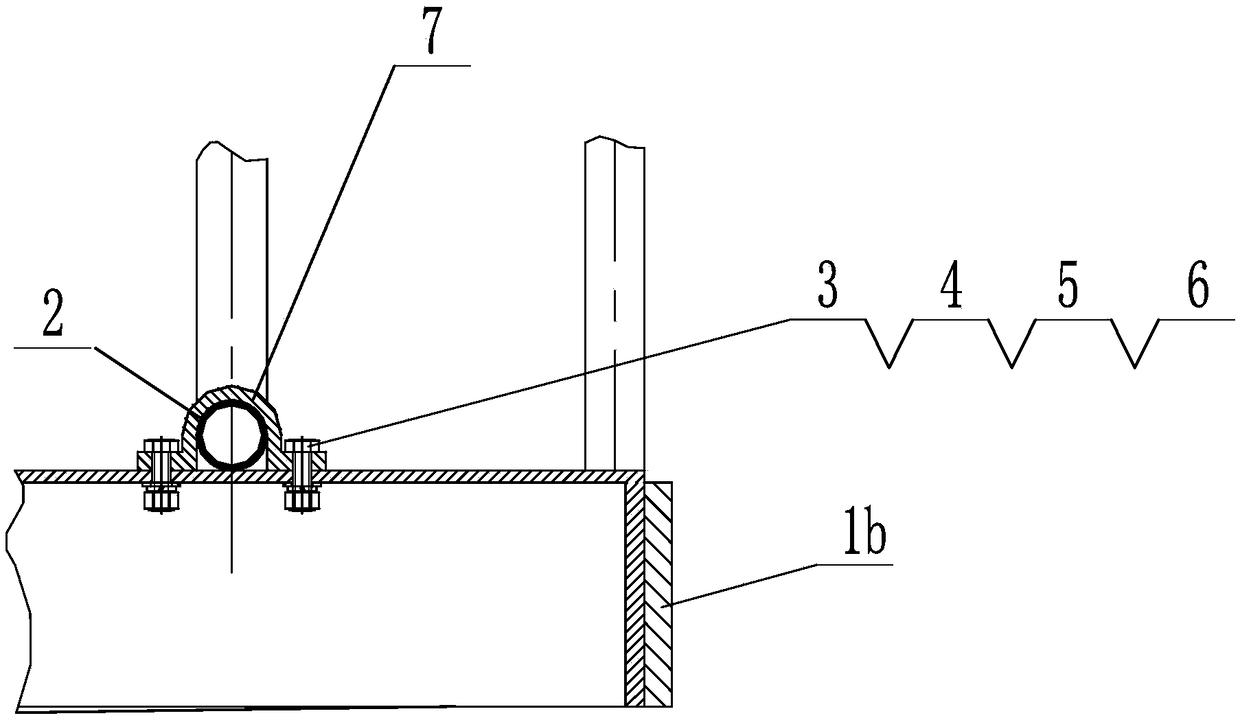

[0022] Such as Figure 1 to Figure 4 As shown, a special vehicle for composite material testing of the outer wing and flat tail of an aircraft includes an electric mobile lifting platform 1, two high-back chairs 9, a testing instrument hanging basket 14, a worktable controller 15, and a guardrail 16. The guardrail 16 Installed on the upper end of the electric mobile lifting platform 1, the two high-back chairs 9 are symmetrically installed on the upper rear part of the electric mobile lifting platform 1, and the two high-back chairs 9 are located in the guardrail 16. The controller 15 is installed in the middle part of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com