Photocatalyst Coating Composition

A technology of photocatalyst and composition, applied in the direction of coating, chemical/physical process, physical/chemical process catalyst, etc., to achieve the effect of stable construction, excellent workability, and low temperature dependence of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

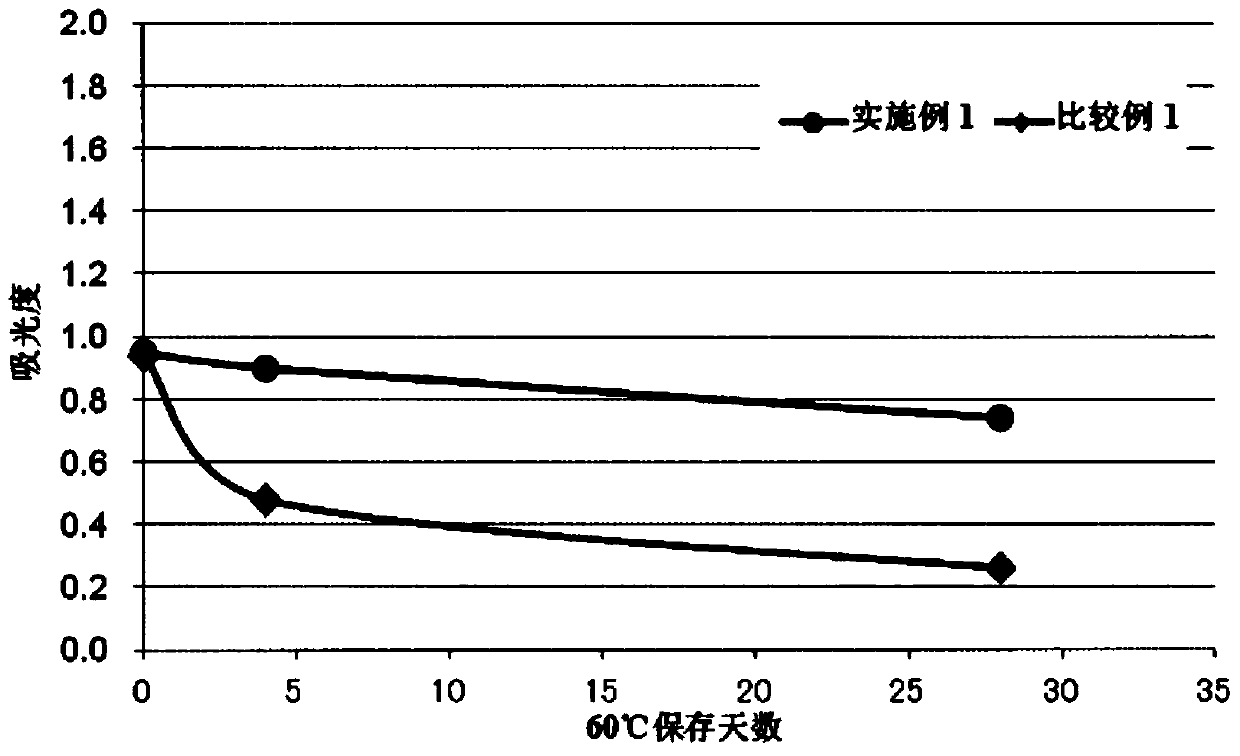

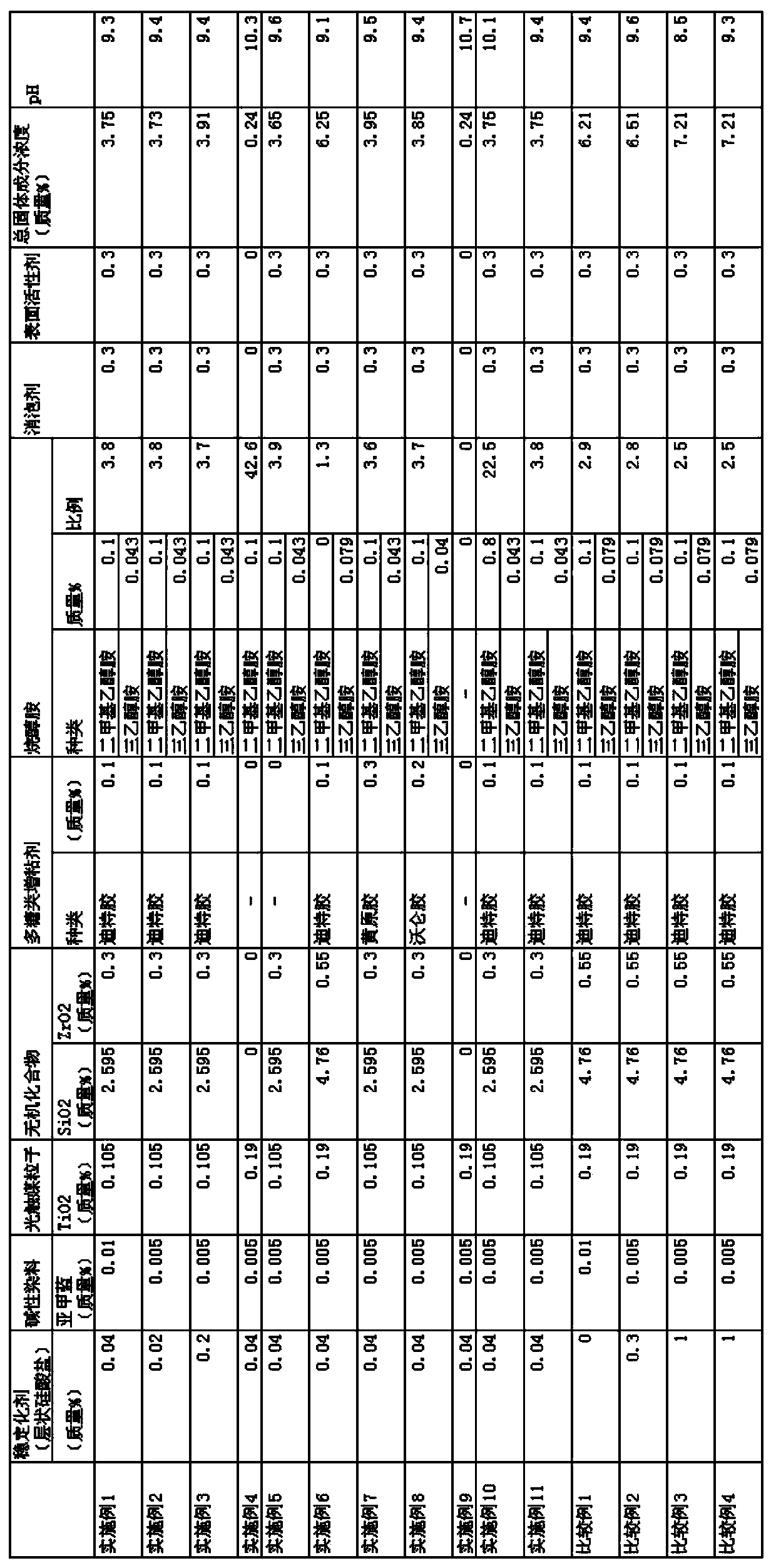

Embodiment 1-11、 and comparative example 1-4

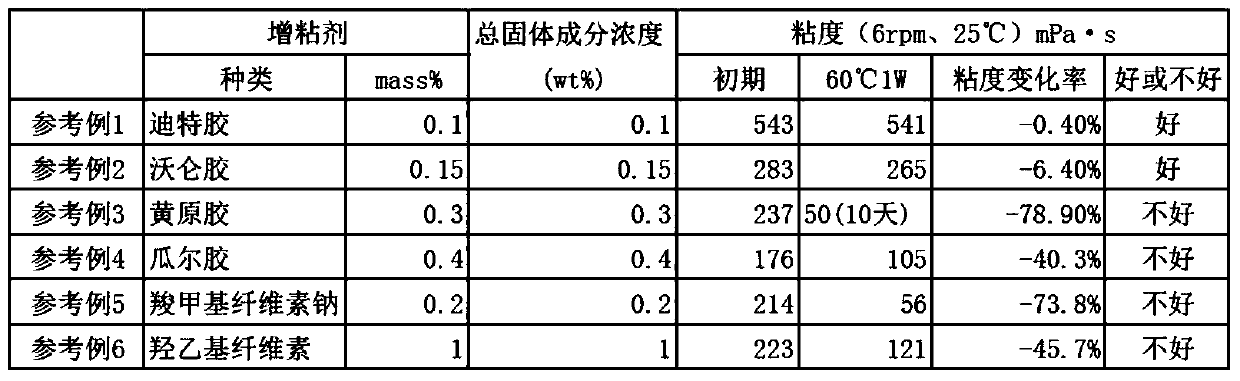

[0093]In Examples 1-11, a prescribed amount of synthetic phyllosilicate as a stabilizer was added to deionized water and sufficiently stirred. In Examples 1-10 synthetic hectorite was used, while in Example 11 synthetic saponite was used. Next, the pre-prepared 1% aqueous solution of methylene blue was gradually added in small amounts. An anatase-type titanium oxide aqueous dispersion was prepared as photocatalyst particles. As inorganic compounds, water-dispersed colloidal silica and zirconia sol were prepared. Thereafter, photocatalyst particles and an inorganic compound were added so that the anatase type titanium oxide aqueous dispersion / water dispersion type colloidal silica / zirconia sol became a predetermined mass ratio. However, in Examples 4 and 9, no inorganic compound was added. Thereafter, a predetermined amount of polysaccharide thickener was added. However, in Examples 4, 5, and 9, no polysaccharide thickener was added. Thereafter, one or two or more selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com