A kind of water-based ink and preparation method thereof

A water-based ink and water-based polyurethane technology, applied in the field of textile printing, can solve the problems of safety and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

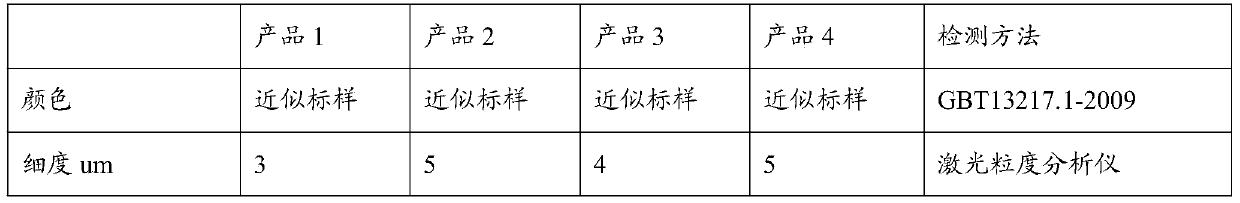

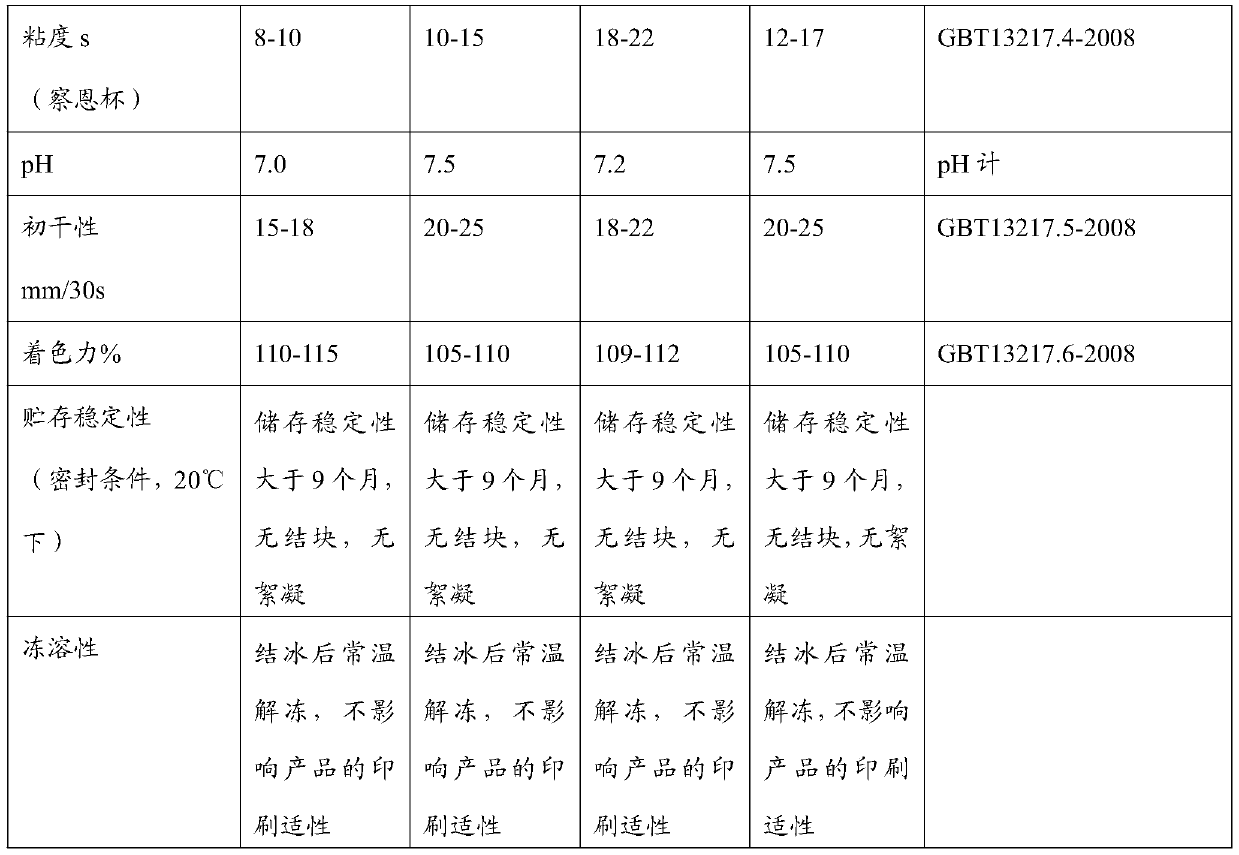

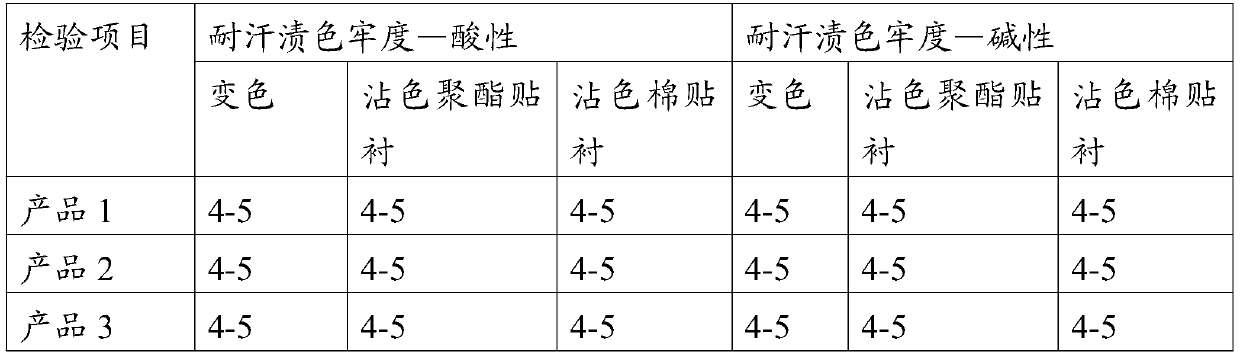

[0021] Weigh 1 kg of dispersant, 10 kg of disperse dye and 40 kg of deionized water, mix them, and grind to obtain the first product 1, the diameter of the first product 1 is less than or equal to 5 μm. After the first product 1 was stirred at a stirring speed of 400 r / min for 20 min, the pH was adjusted to 7.0 to obtain the second product 1. 24kg of water-based polyurethane, 5kg of co-solvent and 20kg of deionized water were sequentially added to the second product 1, mixed, and stirred at a stirring speed of 400r / min for 15min to obtain product 1.

[0022] In the embodiment of the present invention, the dispersant is dispersant MF, the disperse dye is disperse red 60, the water-based polyurethane is cross-linked water-based polyurethane with an acid value of 230 mgKOH / g, and the co-solvent is ethanol.

Embodiment 2

[0024] Weigh 2 kg of dispersant, 50 kg of disperse dye and 12.5 kg of deionized water, mix them, and grind to obtain the first product 2, the diameter of the first product 2 is less than or equal to 5 μm. After the first product 2 was stirred at a stirring speed of 500 r / min for 18 min, the pH was adjusted to 7.5 to obtain the second product 2. 20kg of water-based polyurethane, 8kg of co-solvent and 7.5kg of deionized water were sequentially added to the second product 2, mixed, and stirred at a stirring speed of 450r / min for 20min to obtain product 2.

[0025] In the embodiment of the present invention, the dispersant is dispersant Pingpingjia, the disperse dye is Disperse Yellow 211, the water-based polyurethane is cross-linked water-based polyurethane with an acid value of 230 mgKOH / g, and the co-solvent is ethanol.

Embodiment 3

[0027] Weigh 3 kg of dispersant, 27 kg of disperse dye and 32 kg of deionized water, mix them, and grind to obtain the first product 3, the diameter of the first product 3 is less than or equal to 5 μm. After the first product 3 was stirred at a stirring speed of 450 r / min for 15 min, the pH was adjusted to 7.2 to obtain the second product 3 . 10kg of water-based polyurethane, 10kg of co-solvent and 18kg of deionized water were sequentially added to the second product 3, mixed, and stirred at a stirring speed of 500r / min for 17min to obtain product 3.

[0028] In the embodiment of the present invention, the dispersant is dispersant NNO, the disperse dye is disperse blue 165, the water-based polyurethane is cross-linked water-based polyurethane with an acid value of 230 mgKOH / g, and the cosolvent is ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com