Thermoforming plastic printing ink adopting ultraviolet-infra red drying technology

A plastic printing and infrared technology, applied in the field of printing ink, can solve the problems of human health hazards and environmental pollution of solvent-based ink, and achieve the effects of easy production and application, good flexibility, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

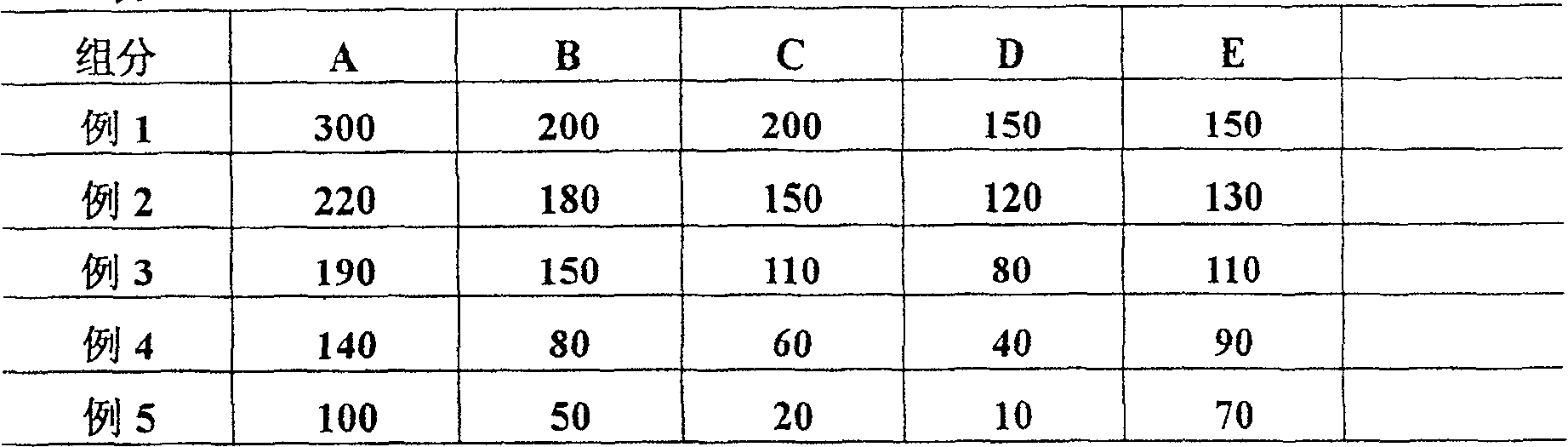

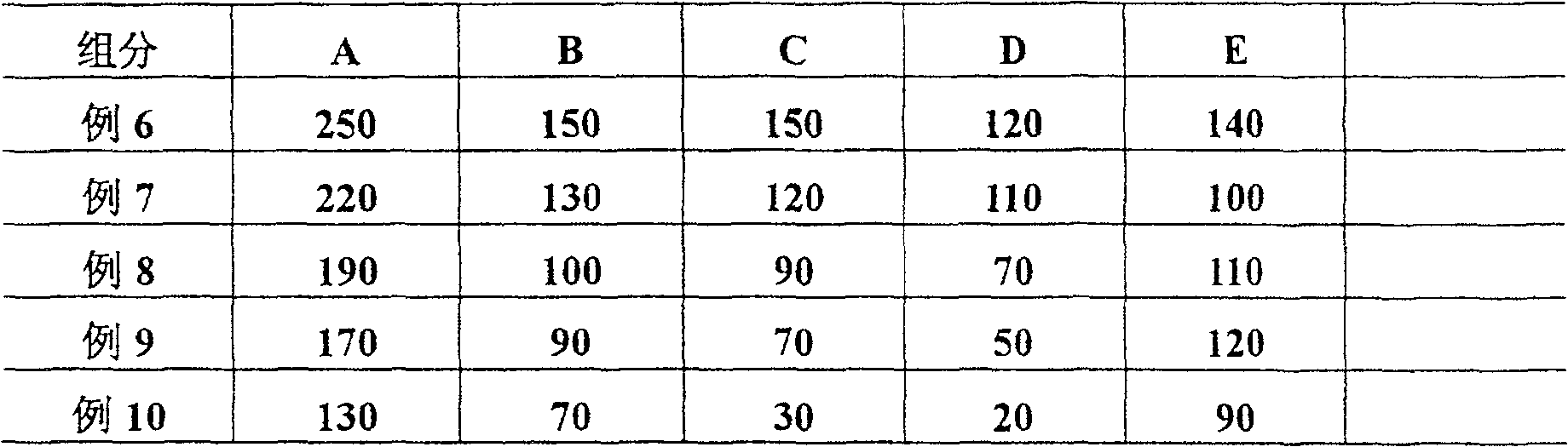

Examples

Embodiment Construction

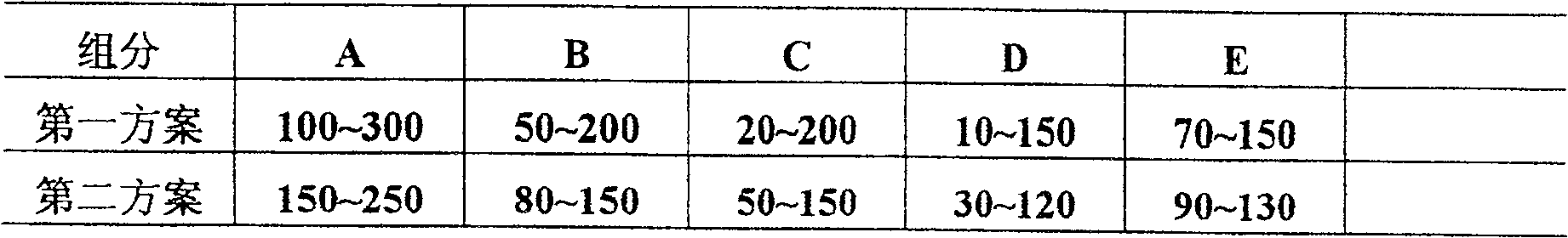

[0009] 1. Raw materials and selection of components

[0010] 1. The prepolymer, also known as an oligomer, is an ultraviolet curable resin, hereinafter referred to as A, which is a low-molecular polymer containing unsaturated functional groups and is the most important component in ultraviolet curable inks. Its performance has great influence on the curing process. And the properties of the cured film play a decisive role. The photoinitiator under ultraviolet irradiation can make the prepolymer and the active monomer into an excited state, continuously cross-link and polymerize, and quickly solidify into a film. It can be composed of one, two or three substances Composition, selected materials are as follows:

[0011] Epoxy acrylic resin, such as: HL-103 series bisphenol A epoxy acrylate [2], modified epoxy acrylic resin HL-140 [1]; ethoxylated bisphenol A diacrylate resin [1];

[0012] Polyurethane acrylic resin, such as: aliphatic polyurethane acrylic resin HL-203Z[2]; poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com