Three-dimensional printing method

A technology of 3D printing and support rods, which is applied in the field of 3D printing, can solve problems such as difficulty in adapting to printed objects, structures that cannot guarantee physical stability, and inflexible rule patterns, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

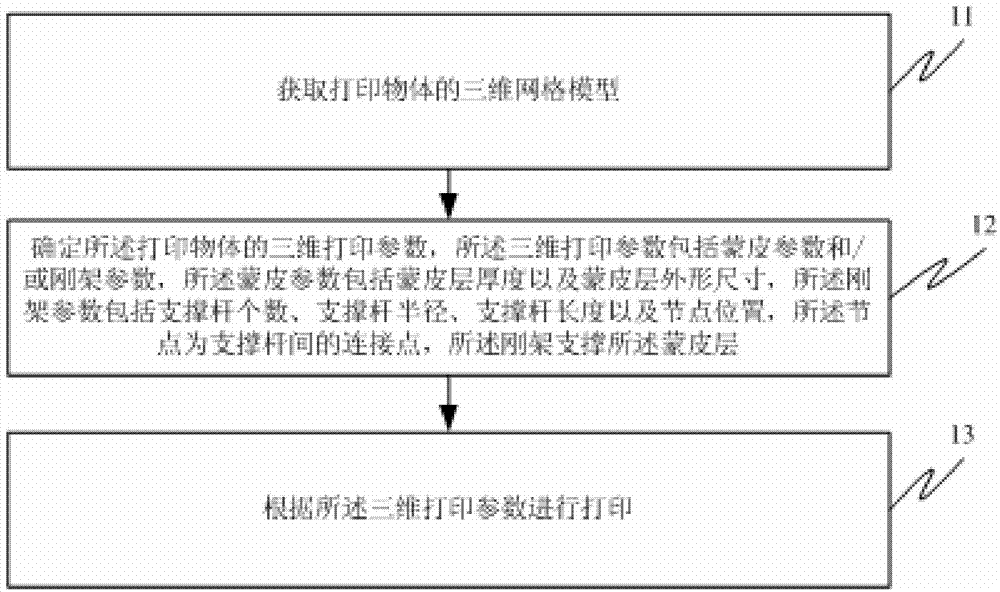

Method used

Image

Examples

Embodiment 3

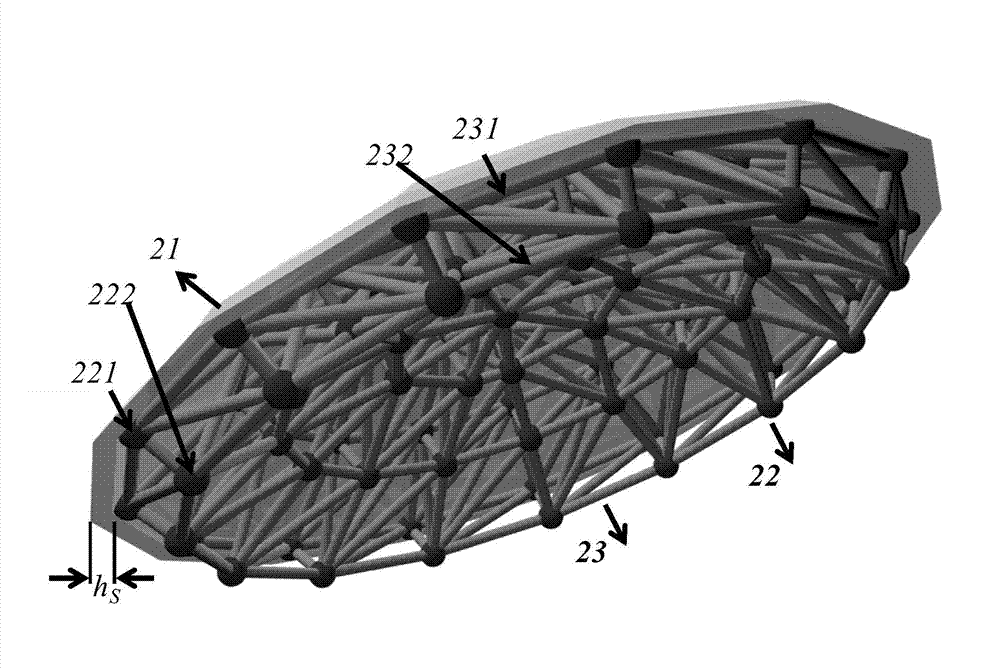

[0031] The three-dimensional printing method of the embodiment of the present invention may also include:

[0032] A multi-objective three-dimensional printing model is established with the constraints of the printing environment and the physical characteristics of the printing material, and with the goal of minimizing the total volume of the support rods and the minimum number of the support rods.

[0033] Specifically, the printing environment may include the lower limit of the printing radius of the three-dimensional printer, and the physical properties of the printing material include tensile or compressive strength σ, shear strength τ, tensile elastic modulus γ, shear modulus μ, Ω Tensile buckling slenderness ratio α, the nodes include surface nodes and internal nodes, and the struts include surface struts and internal struts.

[0034] At this time, the physical characteristics of the printing environment and printing materials are used as constraints, which can include: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com