Synthesis method and preparation process of hyperbranched polymer resin for intaglio ink

A technology of hyperbranched polymer and engraving gravure ink, applied in the field of binder, can solve the problems of synthetic modification of hyperbranched polyester, which have not been reported, and meet the requirements of ink, printability, moderate fixation time, and storage stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Put 0.1mol of phthalic anhydride, 0.89mol of triethylene glycol, 0.1mol of ethanol and 0.005mol of concentrated sulfuric acid into a 500ml four-neck flask equipped with a reflux condensing tube, and pass through an inert gas protection, stir and raise the temperature to 100-160°C for reaction After 12 hours, the by-product was evaporated under reduced pressure, and after cooling, 300ml of ether was added to precipitate and wash to obtain a colorless to light yellow liquid, which was a polyhydroxyl hyperbranched polymer. The yield was 94%, and the weight-average molecular weight was 1750. The molecular weight distribution is 2.2.

Embodiment 2

[0044] Under the same reaction condition of embodiment 1, drop into 0.1mol benzene tetracarboxylic acid and 1.34mol4-hydroxyl isophthalic acid, obtain white solid, be polycarboxy hyperbranched polymer, yield is 92%, weight-average molecular weight is In 2000, the molecular weight distribution was 2.8.

Embodiment 3

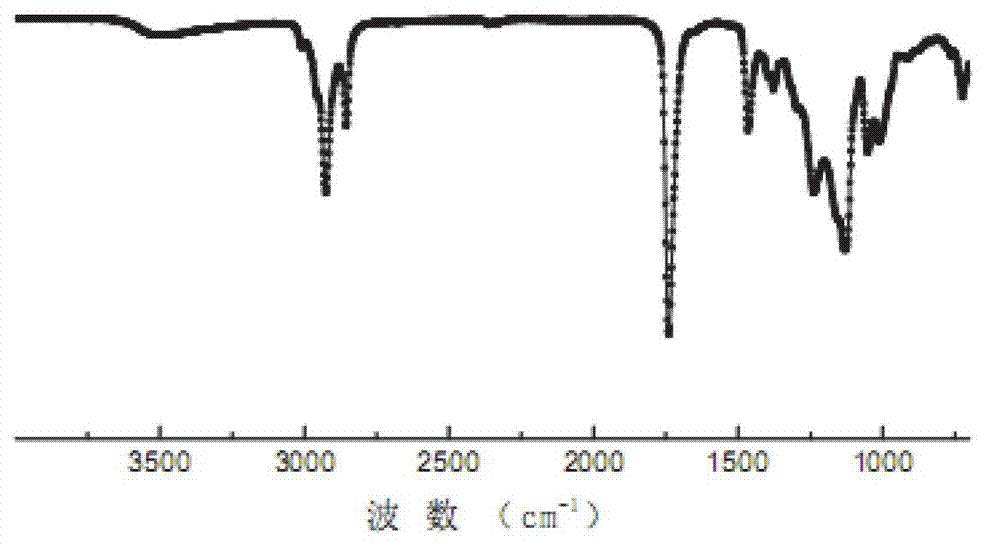

[0046] Select 0.1 mol and 0.8 mol of soybean oil from Example 1 and put them into a 500ml four-necked flask, pass inert gas protection, stir and raise the temperature to 140°C for 10 hours to obtain an amber liquid with an acid value of 35mgKOH / g and a viscosity of 0.5PaS , the weight average molecular weight is 5500, and the molecular weight distribution is 3.5. (Infrared spectrum see figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com