Control method for color cell air door of printing machine

A printing machine color group and damper control technology, applied to printing machines, rotary printing machines, gravure rotary printing machines, etc., can solve the problems of unquantified data, inability to meet intelligent operation requirements, time-consuming and labor-intensive problems, and achieve reduction The effect of small exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] This embodiment provides a method for controlling the color group air door of a printing machine, the printing machine is a five-color (five color groups in total) printing machine, and the rated maximum printing speed of the printing machine is V max =300m / min, specifically follow the steps below:

[0053] Step 1: Install electric damper actuators on the air intake, exhaust and return air dampers of the color group oven;

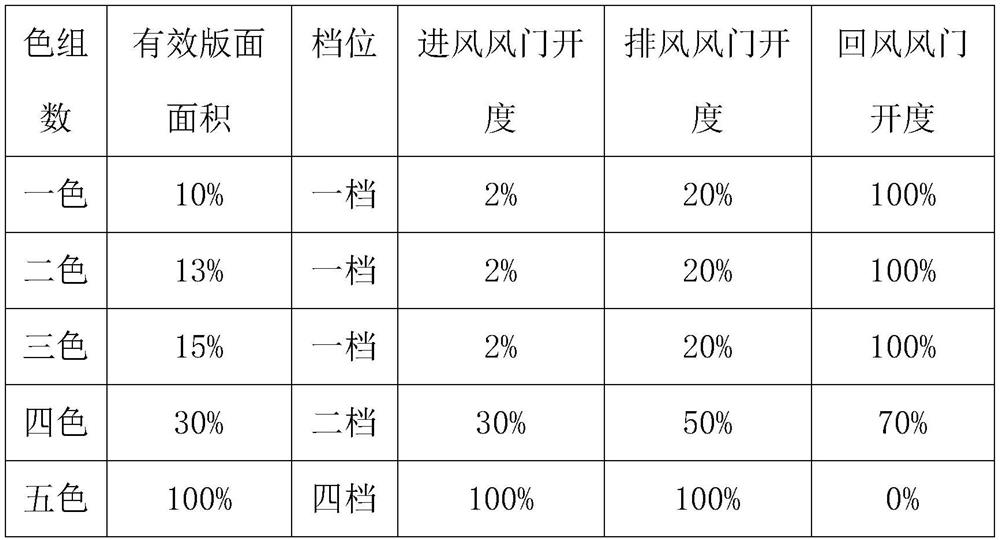

[0054] Step 2: Preset the parameters of the effective layout area range of the color group plate roller, and preset the opening values corresponding to the air inlet, exhaust, and return air damper actuators corresponding to the effective layout area of different plate rollers;

[0055] Step 3: Read the effective printing layout area and total layout area of the color group printing roller on the drawing of the printing roller;

[0056] Step 4: Select the damper gear corresponding to the effective layout area of the color group plate roller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com