Towel embroidery machine head with single cam and three connecting rods

An embroidery machine and three-link technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problem of bloated axial size of the towel embroidery machine head, and achieve the effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

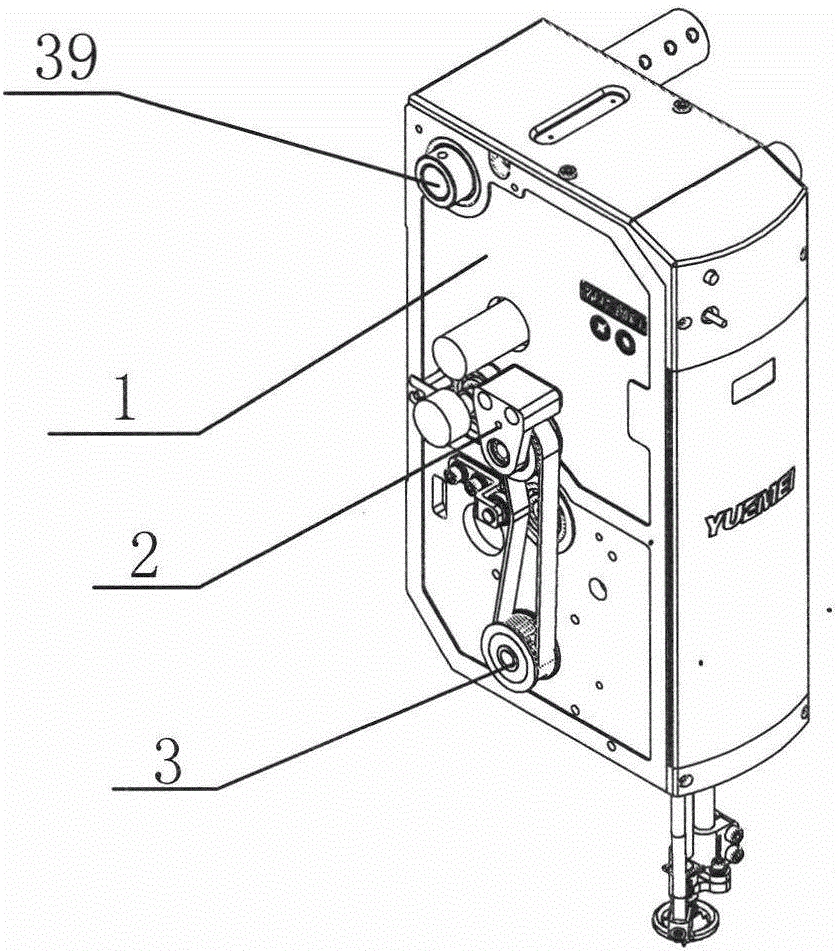

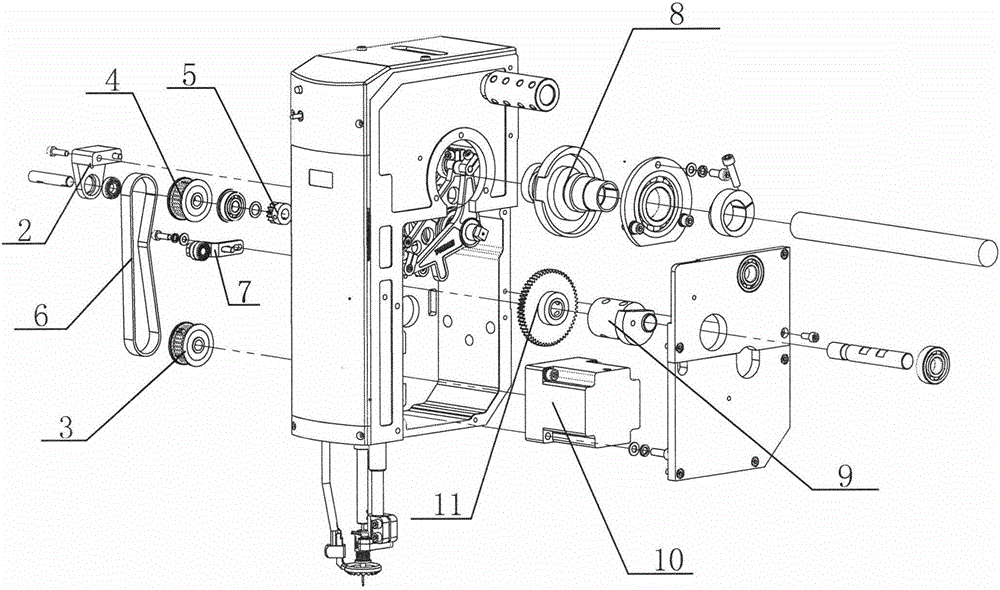

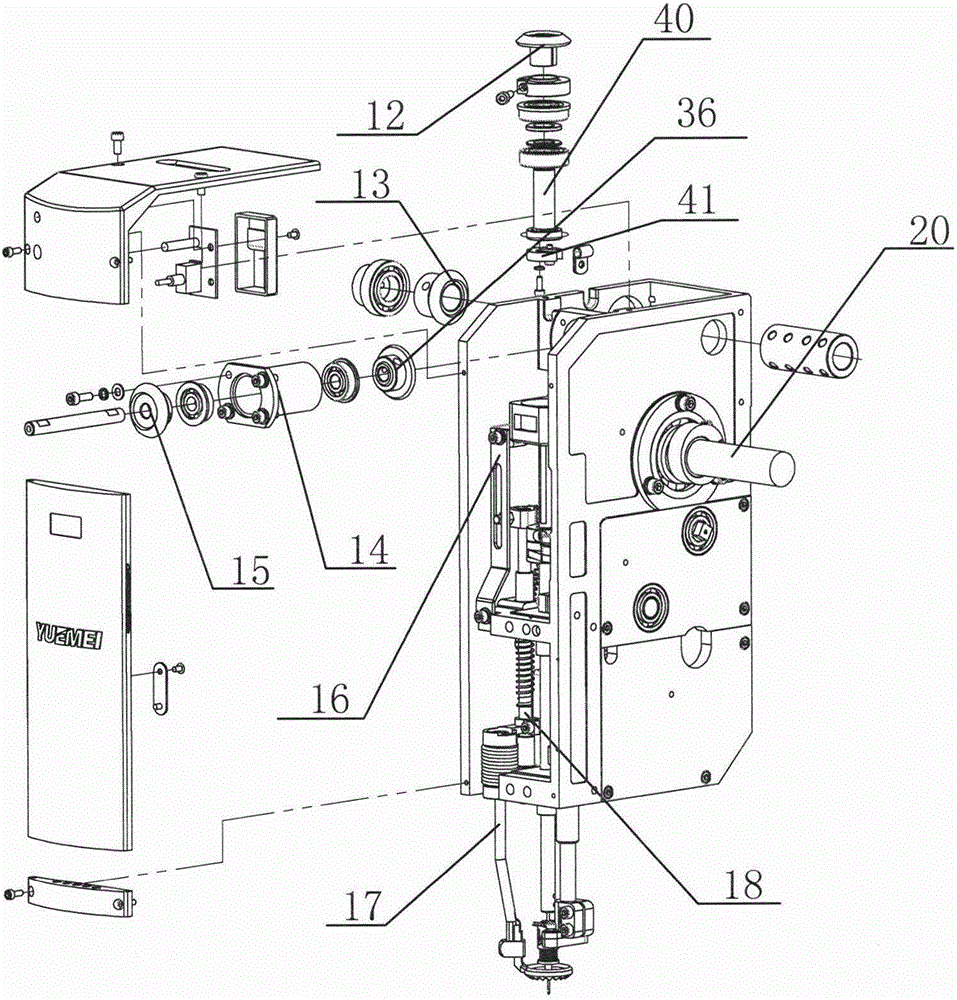

[0017] Such as Figures 1 to 6 A towel embroidery machine head with a single cam and three linkages is shown, including a head housing 1, in which are respectively installed a towel needle up and down driving device, a presser foot up and down driving device that cooperates with the towel needle to move up and down, and Needle nozzle up and down driving device, towel needle up and down driving device, presser foot up and down driving device, needle nozzle up and down driving device are respectively equipped with towel needle connecting rod 25, presser foot connecting rod 23, needle nozzle connecting rod 24, towel needle connecting rod 25 , the presser foot connecting rod 23, and the needle tip connecting rod 24 are all connected with bearings, and the above bearings are all connected to the same cam 8, and the cam 8 is axially provided with a towel needle cam track ring, a presser foot cam track ring, a needle tip The cam track ring, the towel needle cam track ring, the presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com