A high-voltage inverter multi-IGBT clock synchronous driving method and system

A high-voltage frequency converter, clock synchronization technology, applied in the output power conversion device, electrical components and other directions, can solve the problem that the function index cannot achieve the expected effect, the IGBT drive pulse is not synchronized, the local clock is not synchronized, etc., to avoid failures. Potentially risky, easy-to-achieve, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

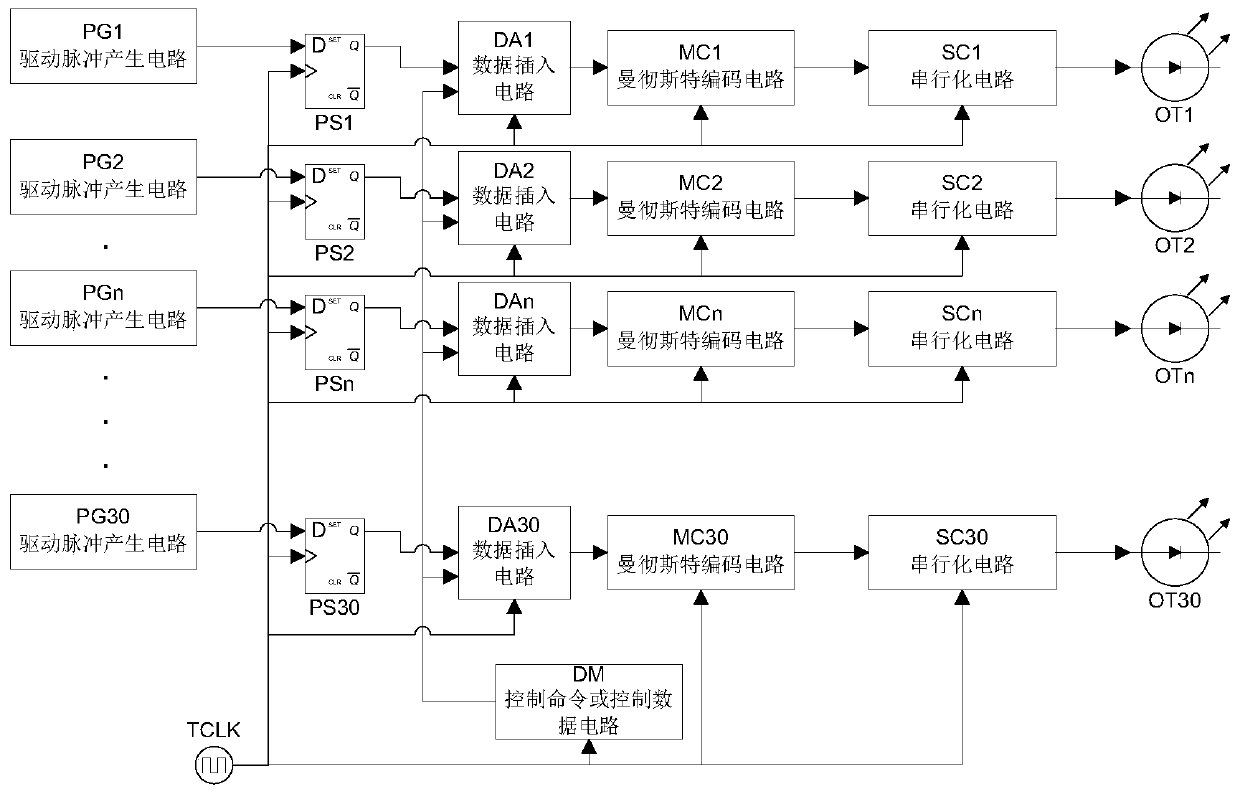

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

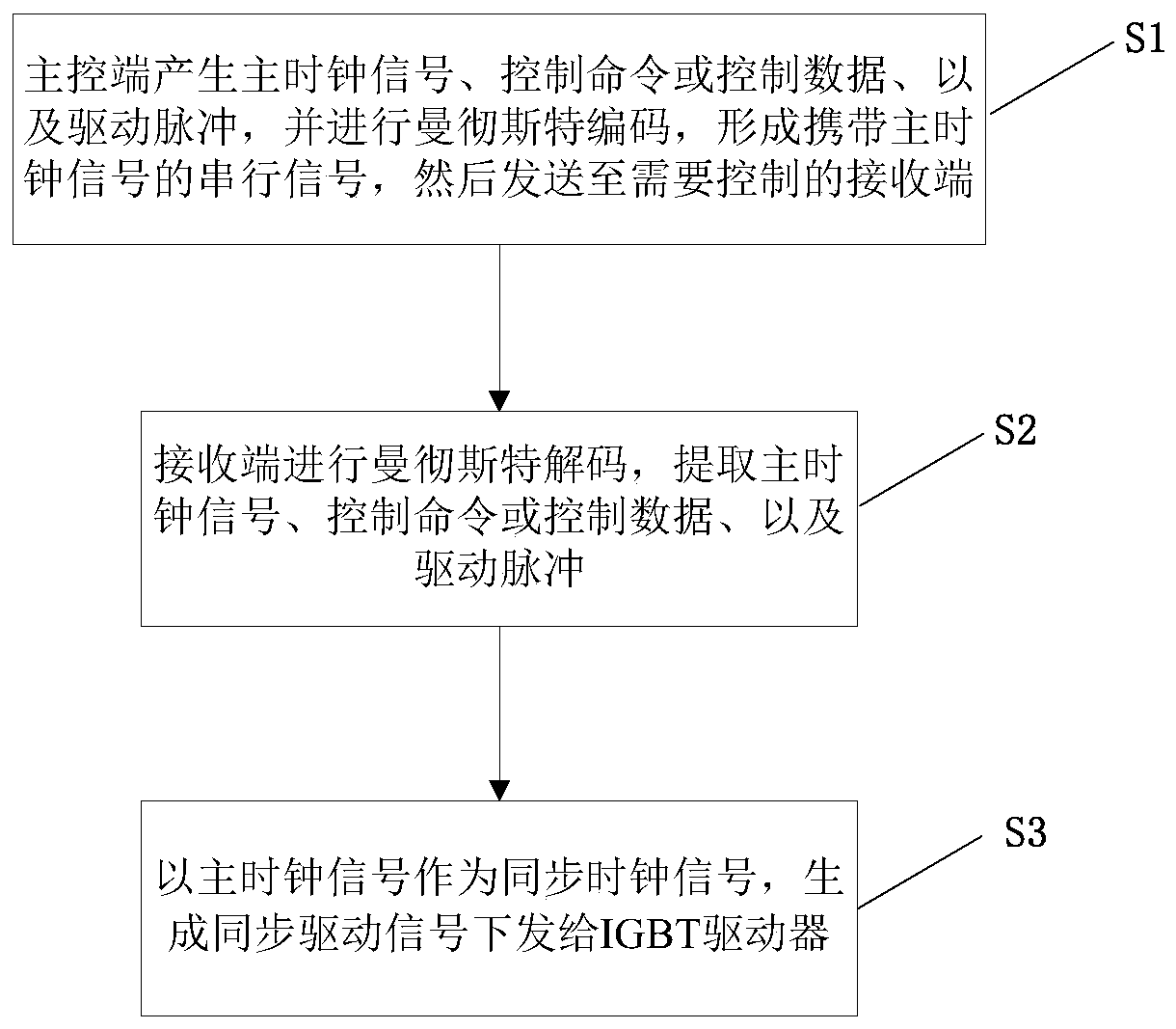

[0049] see figure 1 As shown, the embodiment of the present invention provides a high-voltage inverter multi-IGBT clock synchronous driving method, which includes the steps:

[0050] S1. The main control terminal generates the main clock signal, control command or control data, and driving pulse, and performs Manchester encoding to form a serial signal carrying the main clock signal, and then sends it to the receiving end that needs to be controlled; the control command or control data carries The address code of the above receiving end.

[0051] S2. The receiving end performs Manchester decoding to extract the main clock signal, control command or control data, and driving pulse.

[0052] S3. Using the main clock signal as a synchronous clock signal, generating a synchronous driving signal and sending it to the IGBT driver.

[0053] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com