Steel plate needle file preventing selvage from becoming hard

A steel plate, needle seat technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., to achieve uniform humidity and improve fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

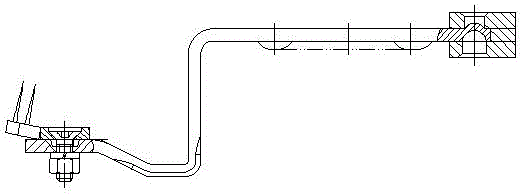

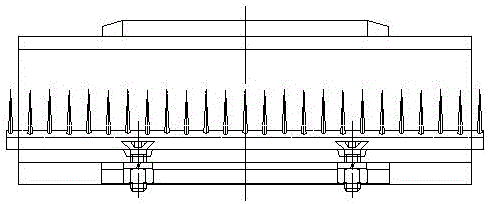

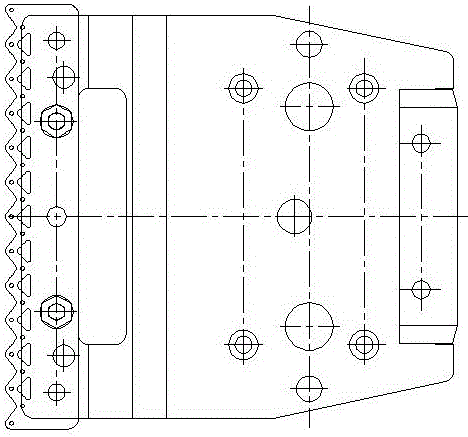

[0016] Embodiment 1: A steel plate needle holder for preventing cloth edges from hardening, including a plate body 1, a needle plate 2 installed at the front of the plate body 1, and two rows of pinholes arranged at the front end of the needle plate 2, and the pinholes are arranged horizontally Arrangement, the needle body 3 is arranged in the pinhole, the connecting hole is opened on the connecting surface between the rear end of the needle plate 2 and the front part of the plate body 1, the connecting hole is a countersunk hole, and the front part of the plate body 1 is opened with a hole corresponding to the connecting hole. The connection hole and the through hole are provided with screws 4, which are screwed and fastened by nuts 5. There are also 7 heat dissipation holes 6 on the connection surface between the rear end of the needle plate 2 and the front part of the plate body 1, and the plate body 1 Corresponding to the heat dissipation holes 6, there are heat dissipation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com