Water-sand separation structures suitable for straight-line steep channel spillways

A technology of water and sand separation and spillway, applied in the field of sand removal, can solve the problems of few water and sand separation measures, small probability of large particles and loose particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

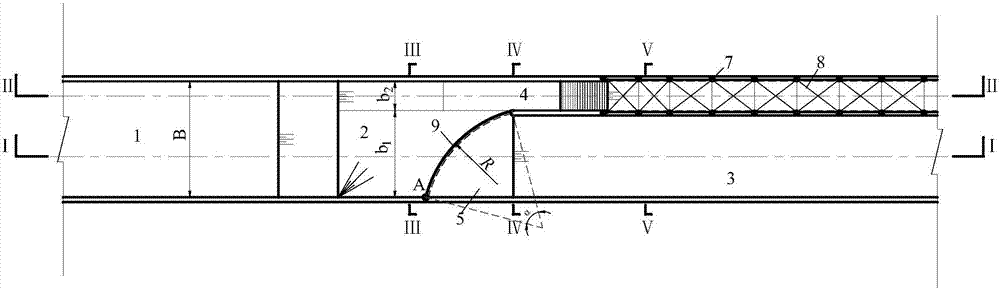

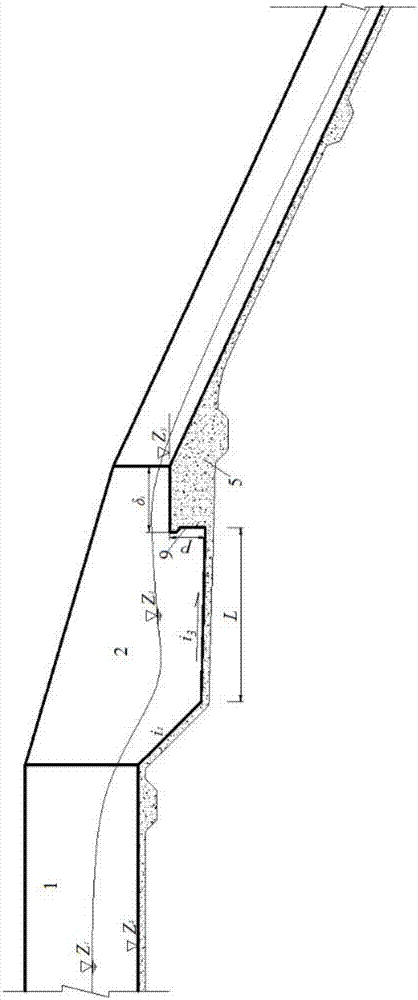

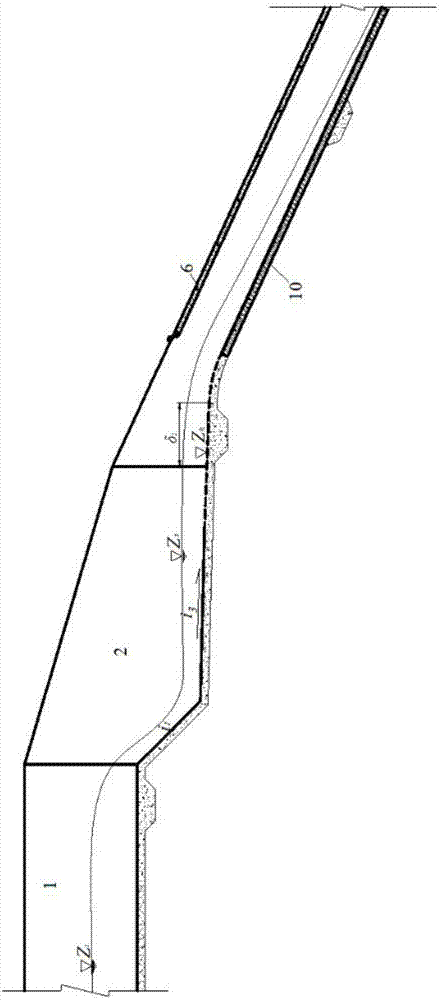

[0068] The implementation examples of the present invention are given below in conjunction with the accompanying drawings, and the present invention will be further described through the examples. It is necessary to specify here that the specific implementation of the present invention is not limited to the forms in the examples. According to the disclosed content of the present invention, those skilled in the art can also implement in other specific ways. Therefore, the examples It should not be understood as a specific embodiment that the present invention can only implement.

[0069] Engineering example

[0070] The example of this project is the flood drainage system of a construction stockyard of a hydropower station. The stockyard is located in a debris flow ditch. The upstream of the stockyard uses a retaining dam to intercept the upstream flow and sand, and a drainage tunnel is used in front of the retaining dam. The sand is guided to a suitable location, and then rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com