A push flow mechanism and flow push method for range hood

A range hood and fan technology, which is applied in the fields of removing oil fume, heating method, household stove/stove, etc., can solve the problems of complex structure of the range hood and no boosting effect of oil fume, and achieve the effect of improving the suction and exhaust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the embodiments of the accompanying drawings.

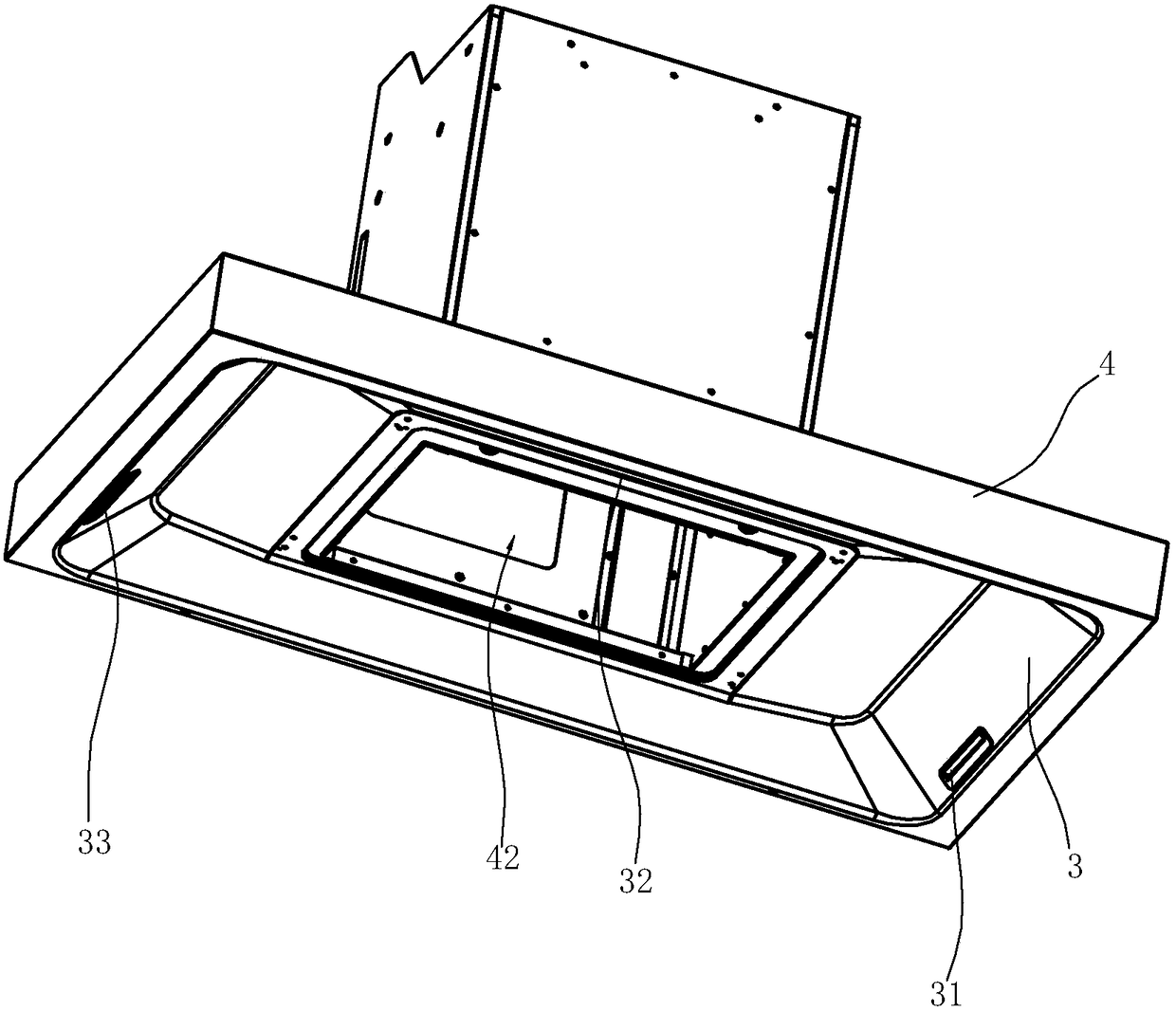

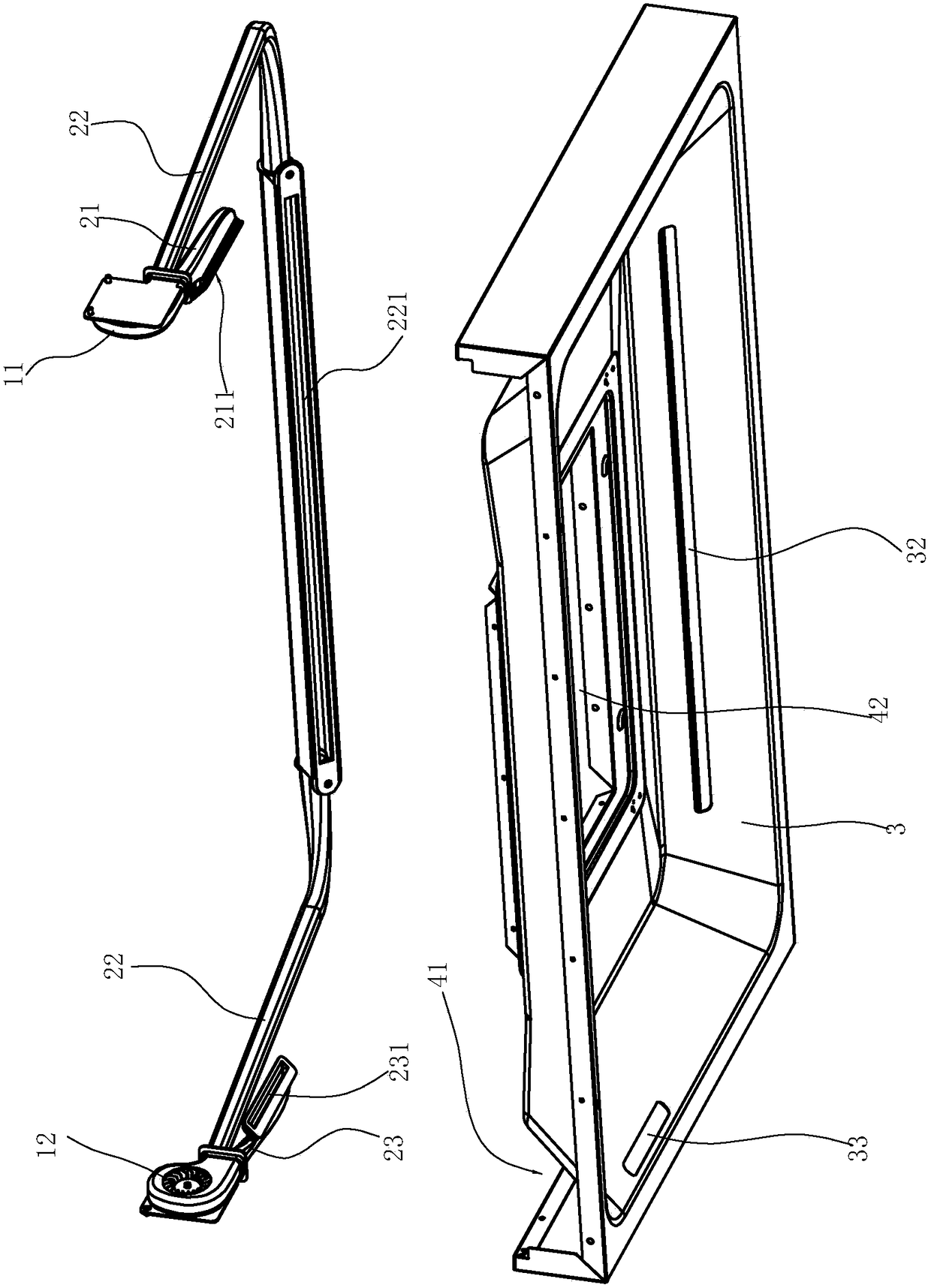

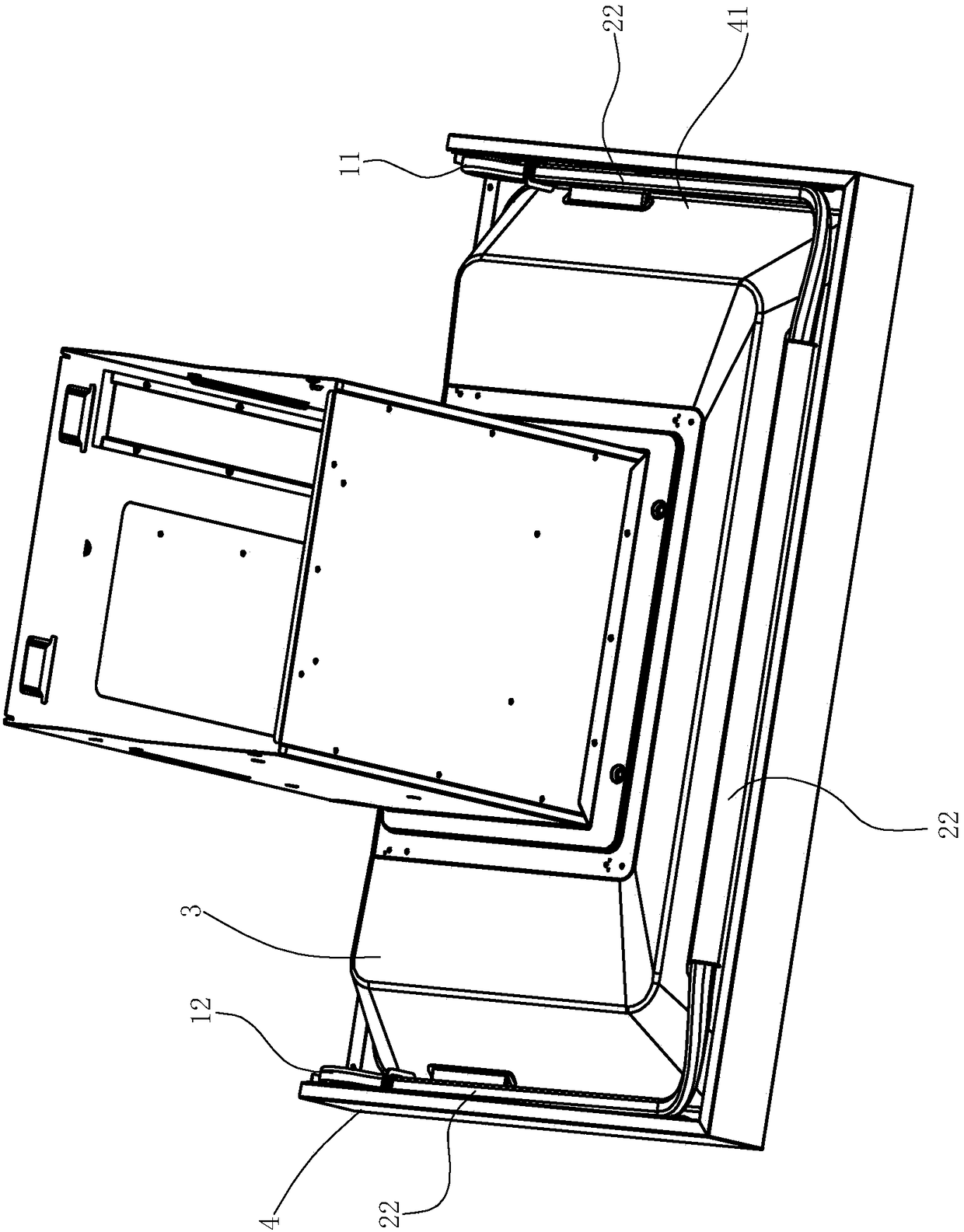

[0037] Such as Figure 1 to Figure 6 As shown, the push flow structure of the range hood is installed in the cavity 41 between the shell 4 of the range hood and the smoke collection hood 3, and the three sides of the smoke collection hood 3 are respectively provided with a first vent 31, The second ventilation opening 32 and the third ventilation opening 33, wherein the second ventilation opening 32 is arranged in the side cavity close to the cook, and the other two ventilation openings are arranged in the left and right side cavities.

[0038] The pushing flow structure of the range hood includes an air supply device, and the air supply device is composed of two buttons, two fans, a control chip (not shown in the figure) and three air guide pipes.

[0039] Wherein, the first switch 13 and the second switch 14 are arranged on the housing 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com