SMD automatic testing machine

An automatic testing machine and testing mechanism technology, applied in measuring devices, instruments, material analysis by optical means, etc., can solve the problems of high labor cost, low production efficiency, error-prone, etc., and achieve a high degree of automation, simple structure, less error-prone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

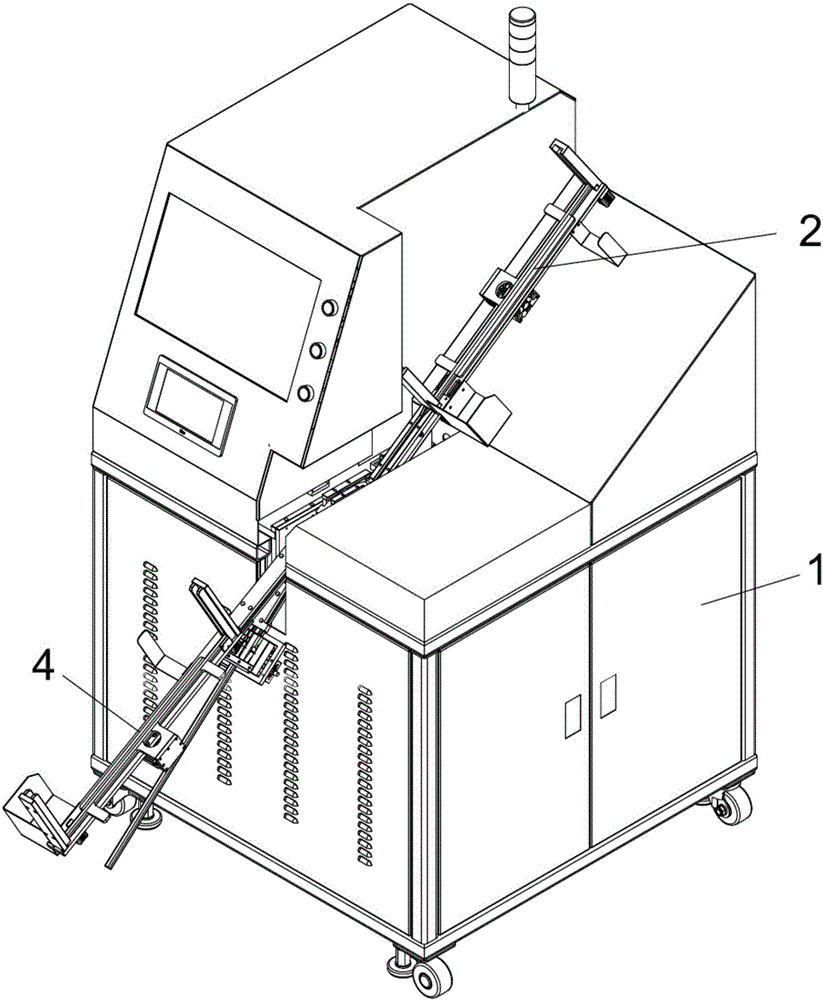

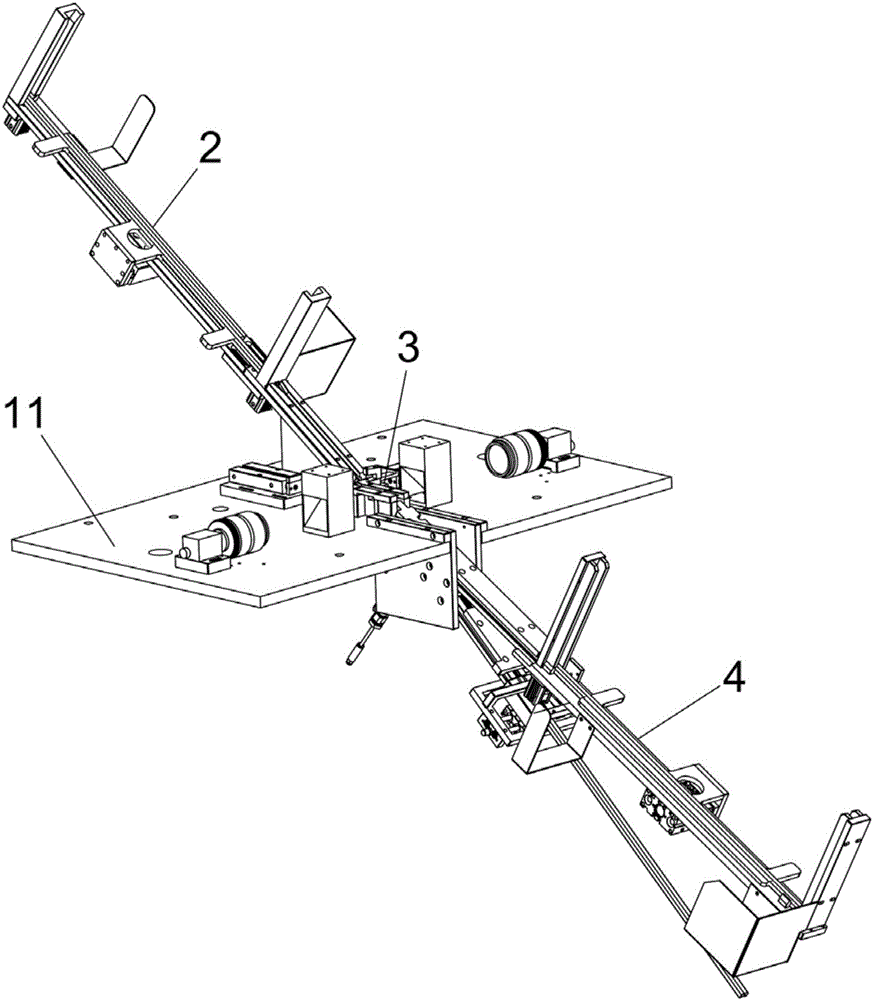

[0030] refer to figure 1 , figure 2 , a kind of SMD automatic testing machine of the present invention, comprises body 1, is provided with detection mechanism assembly 3 on the body 1 and is arranged on the feeding mechanism assembly 2 of the feeding end of detection mechanism assembly 3, is arranged on detection mechanism assembly The receiving mechanism assembly 4 of the discharge end of 3.

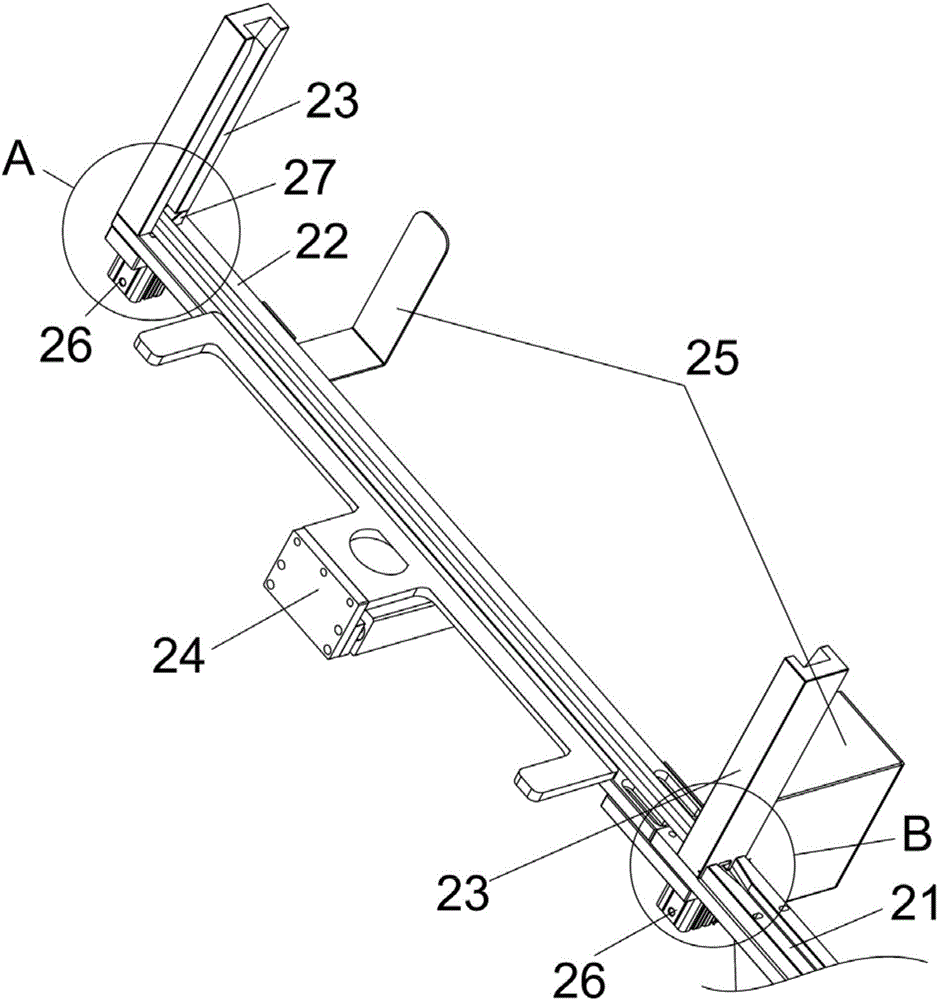

[0031] refer to Figure 6 , Figure 7 , the detection mechanism assembly 3 includes a detection channel 34 of L-shaped structure, the detection channel 34 includes an X-axis section 341 and a Y-axis section 342 that are connected to each other and are vertical, and the described blanking mechanism assembly 2 includes a blanking channel 21. The feeding channel 21 is perpendicular to the detection channel 34 of the X-axis section 341 and communicated with it. The end of the detection channel 34 of the X-axis section 341 is provided with a device for pushing the material 5 in the X-axi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap