Electromechanical valve

A valve, electromechanical technology, applied in the direction of lift valve, circuit, electromagnet, etc., can solve the problems of dust sensitivity, easy wear, easy to block the working medium and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

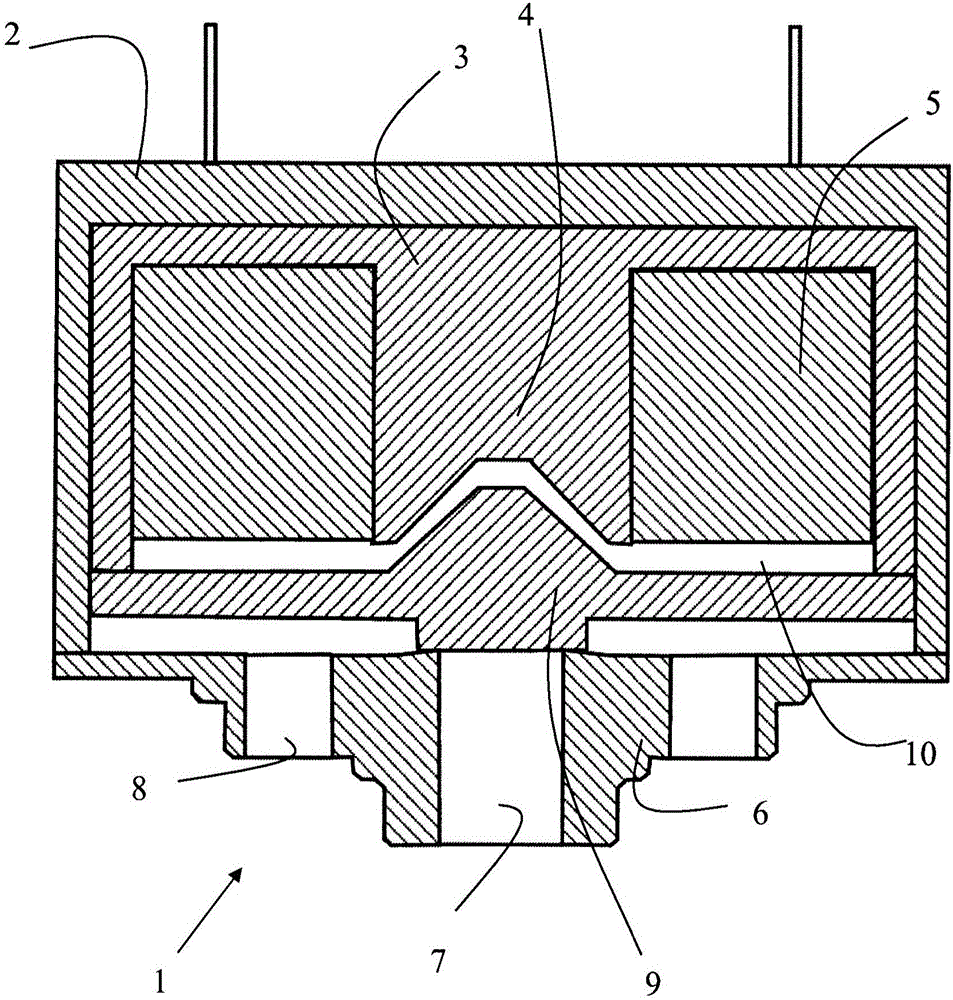

[0023] figure 1 An axial sectional view of an embodiment of an electromechanical valve 1 , for example a pneumatic valve, is shown. The valve can be designed to operate with fluids other than air.

[0024] The electromechanical valve 1 comprises a housing 2 made of a non-magnetic material such as aluminium. Inside the housing 2 is a core 3 made of electromagnetic material. The core 3 has a central extension 4 around which a coil 5 surrounds. In one embodiment, the core 3 is generally cup-shaped. In one embodiment, the core 3 may be U-shaped. Other shapes are also possible, eg E-shape.

[0025] In one embodiment, the central portion 4 extends to the edge of the cup-shaped magnetic core 3 . It should be understood, however, that the portion 4 may be shorter or longer than the height of the wall of the core.

[0026] The coil 5 is supplied via its terminals with excitation current from a current source, as hereinafter incorporated Figure 13 shown.

[0027] Preferably, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com