A rotary cultivator with an automatic following clutch device

A clutch device and automatic follow-up technology, applied in the field of rotary tillers, can solve the problems of greatly increased rotational resistance of rotary tillers, overload damage of tools, and decreased rotary tillage efficiency, and achieves the effect of solving insufficient torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

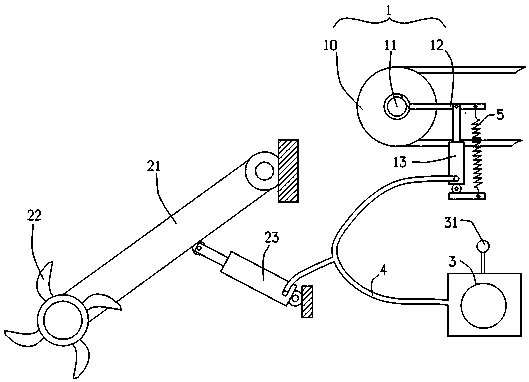

[0010] figure 1 It shows an embodiment of a rotary cultivator with an automatic following clutch device, including a belt clutch wheel 1 driven by power. The belt clutch wheel 1 includes a pulley 10, an output shaft 11, and a separation pawl 12. The output shaft 11 drives the rotary cultivator. , the rotary tiller includes a transmission box 21 that is hinged at one end on the frame, and the rotary tiller 22 is installed at the other end of the transmission box 21; the hydraulic cylinder one 23 is connected to the transmission box 21, and can push the transmission box 21 around the hinge Point rotation to lift the working position of the rotary tiller 22, the hydraulic cylinder two 13 is connected to the separation claw 12 of the belt clutch wheel 1, and the separation claw 12 can be promoted to rotate to disconnect the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com