Single-drive guide anti-crushing ratooning rice harvester with three traveling wheels and use method of harvester

A technology of walking wheels and regenerated rice, which is applied in the directions of harvesters, applications, cutters, etc., can solve the problems affecting the production of regenerated rice, and achieve the effect of realizing telescopic movement and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

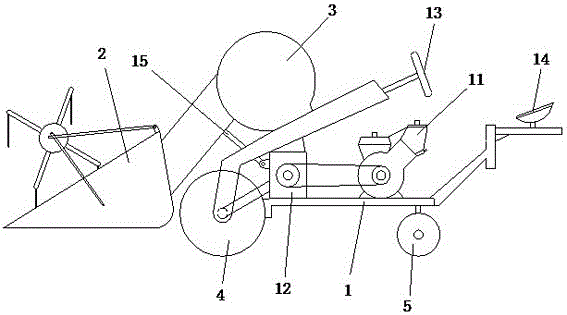

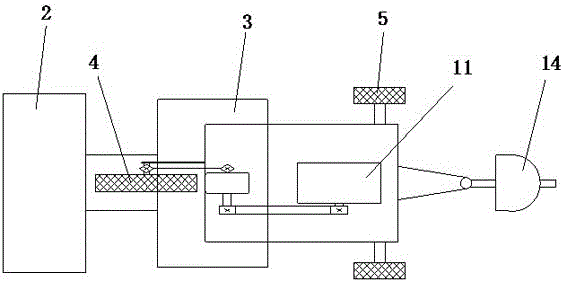

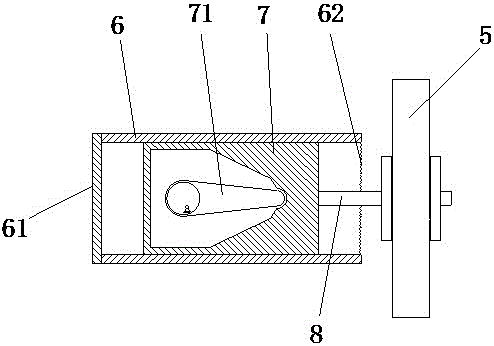

[0021] Example 1: as Figures 1 to 3 As shown, a single-drive guided three-wheeled anti-rolling regenerated rice harvester includes a chassis 1 and a control system. The front end of the chassis 1 is provided with a header 2 for harvesting rice ears and a threshing device 3 for threshing the rice ears. , the bottom ends of the chassis 1 are provided with a driving wheel 4 and two auxiliary wheels 5 arranged in an isosceles triangle, the driving wheel 4 is also used as a guide wheel, the driving wheel 4 is located at the front end, and the auxiliary wheel 5 is located at the rear Two telescopic mechanisms respectively connected with auxiliary wheels are provided on both sides of the bottom of the chassis 1, and the telescopic mechanism includes an outer sleeve 6 and a motor fixed at the bottom of the chassis, and the outer sleeve 6 is provided with a motor. The slider 7, one end of the slider 7 is hinged with a crank 71, the other end of the crank 71 is connected to the output ...

Embodiment 2

[0029] Embodiment 2: Its structure is the same as that of Embodiment 1, the difference is that the driving wheel is located at the rear end, and the auxiliary wheel is located at the front end, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com