Removable denture and manufacturing process thereof

A removable denture and manufacturing process technology, applied in the field of oral prosthesis, can solve the problems of large volume of removable dentures, foreign body sensation in patients, metal snap rings, etc., and achieve the effects of realistic and beautiful appearance, reduced production, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

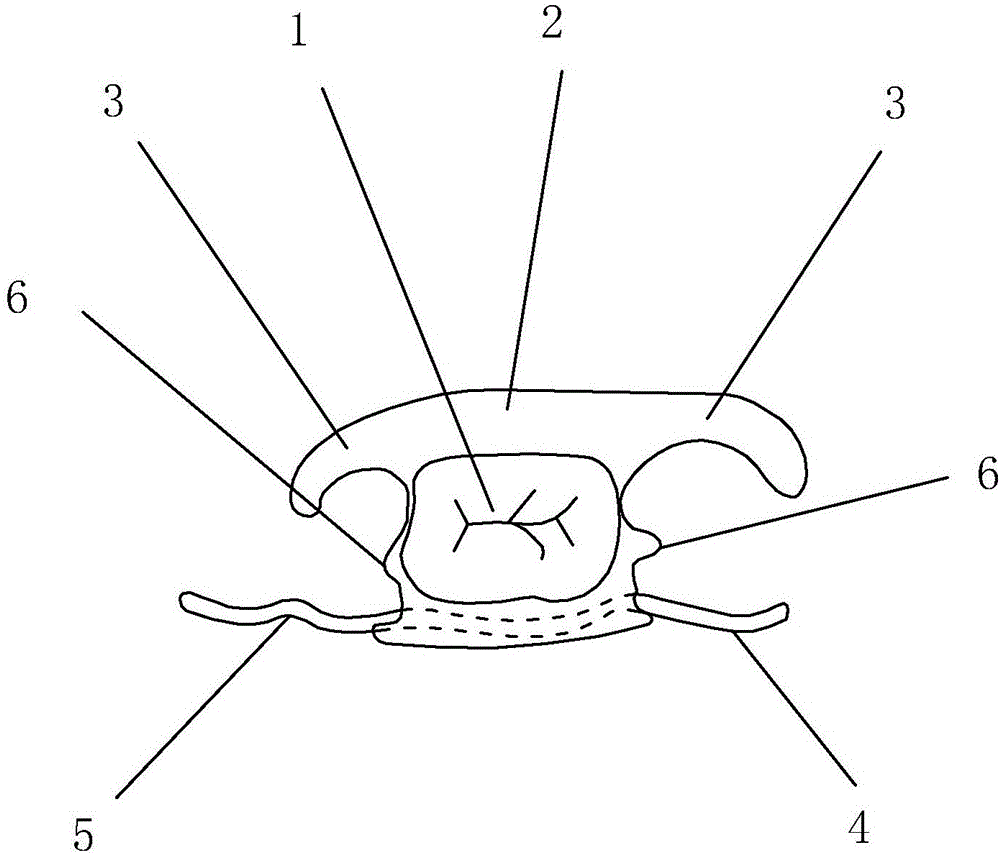

[0031] A removable denture, such as figure 2 , 3 , 4, including bionic teeth 1 and base 2, the bionic teeth 1 is fixed on the base 2, the lip and buccal sides of the base 2 are integrally provided with bionic resin fixing snap rings 3 extending to both ends, the base 2 tongue and palate The side is fixed with a stainless steel wire curved clasp 4 and / or a stainless steel continuous clasp 5 extending to both ends, and the bionic resin fixed clasp 3 and stainless steel wire curved clasp 4 are formed on both sides of the base 2 to be fixed with the natural teeth. The fixed area of the base 2 is provided with dental rests 6 made of bionic resin near the two sides of the fixed area.

[0032] The base 2 is fixed on the edentulous area of people's gums, and the bionic resin fixing clasp 3 is fitted on the lip and buccal sides of the abutments on both sides of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com